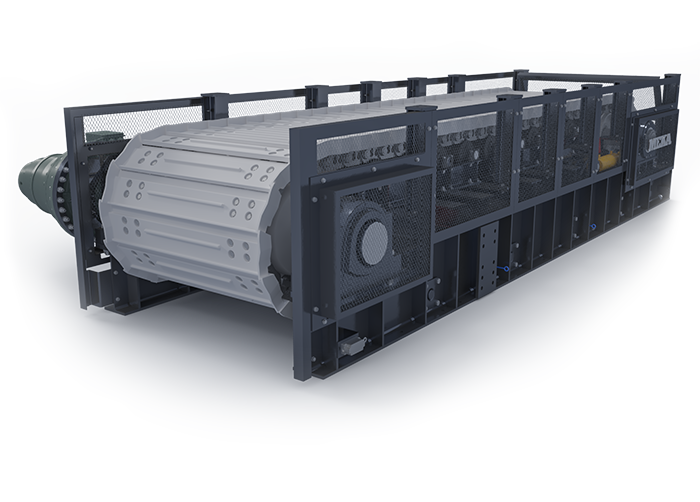

Apron Feeder Gallery

Unparalleled performance in feeding challenging materials

In quarries, stone veins are frequently encountered, where feeding is problematic during the rainy winter months. Apron feeders are the ideal solution for these types of materials. While their investment costs are higher than those of other feeders, their ability to be used in all conditions makes them a preferred choice. For these excellent, wet, and sticky materials, an MWF-type wobbler feeder or grizzly scalper feeder is installed after the pallet feeder, separating unwanted material before the crusher and feeding clean material to the subsequent crusher.

MEKA Apron Feeders are designed for these challenging material handling operations in mining, ore, coal, and aggregate production. With a heavy-duty chassis, drive unit, pallet, and chain system to ensure an extremely long service life, they exceed your expectations.

Applications

In open-pitand underground mining, above-ground and below-ground material transportation

In operations such as truck and ship loading/unloading, as a mobile, compact, and stationary system component

Hopper unloading, primary or secondary crushing stage (feeding of the crusher or screen)

Increased plant efficiency with regular feeding

Apron Feeder Technical Specifications

| Width (mm) | *Capacity (mtph) | Max Feed (mm) | Chain Speed (m/s) | |

| 900 | 110-350 | 380 | 0,1 - 0,30 m/s | |

| 1200 | 230-680 | 520 | 0,1 - 0,30 m/s | |

| 1500 | 350-1100 | 650 | 0,1 - 0,30 m/s | |

| 1800 | 600-1750 | 830 | 0,1 - 0,30 m/s |

*Capacity Figures are provided for: 50% Bed Depth, 0,1-0,3m/s chain speed and for material weighing 1.6 t/m³ or 100 lbs/ft³. Capacity values are indicative only and depend not only on feeder size but also on feeder inclination, feed gradation, etc. Other sizes are also available on request

Would you like to request a quote or receive information about a apron feeder?

Would you like to receive a price quote for a MEKA apron feeder?

Do you need a apron feeder with different options and configurations?

Do you want to become a MEKA apron feeder dealer?

Let's move on to the next level. Contact us now by filling out the form.

What is Apron Feeder?

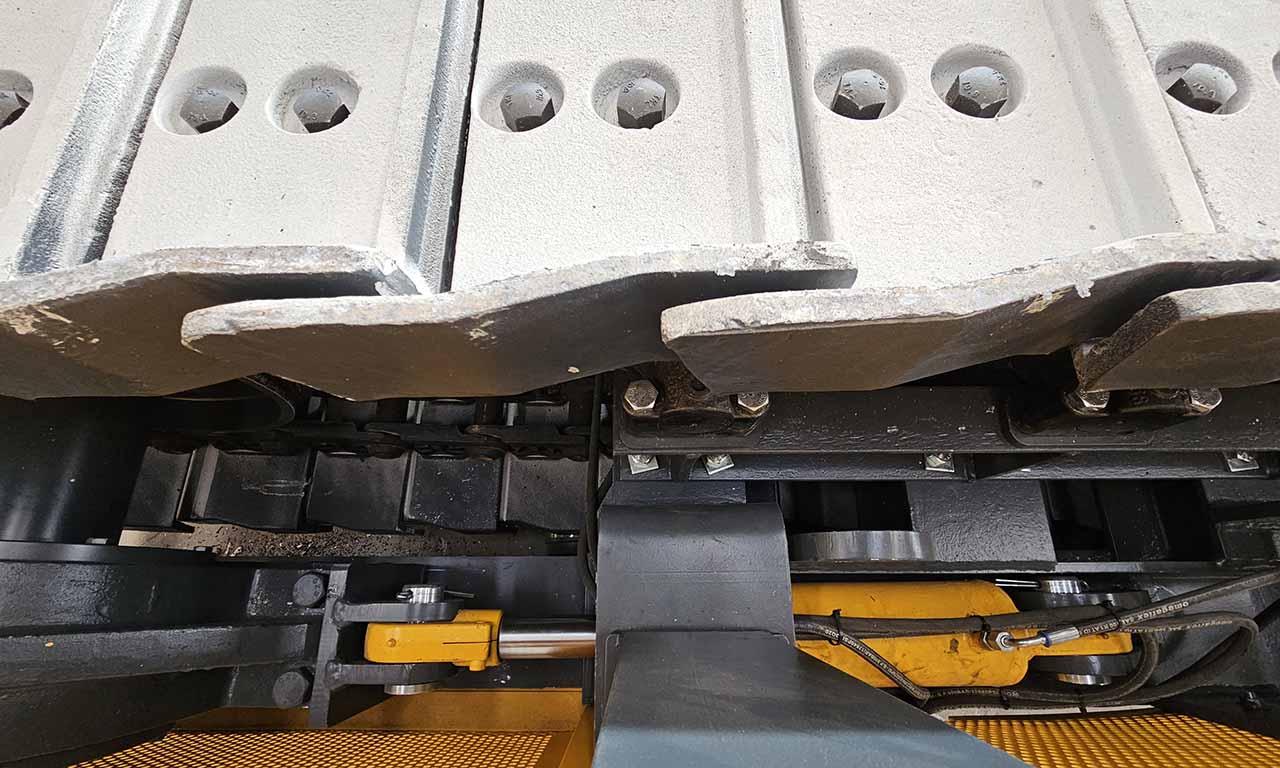

Consisting of articulated metal plates (steel or cast metal), the apron feeder works in principle like a conveyor belt. The aprons are supported by rollers and rotates slowly between the drive pinion and the tail pinion.

Types of Apron Feeder

How Does Apron Feeder Work?

Advantages of Using Apron Feeder

Apron feeder's heavy-duty construction and durable components ensure minimal maintenance and parts requirements.

Apron feeders can be customized to meet a wide range of applications. They provide better feed control to feed material to downstream equipment.

Apron Feeder Processes Applications

Apron feeders are heavy duty equipment and are widely used in mining applications such as rock quarries, gold ore, iron ore, coal and other bulk material handling industries.

Apron feeders are indispensable if the material to be fed is moist, sticky or contains clay.