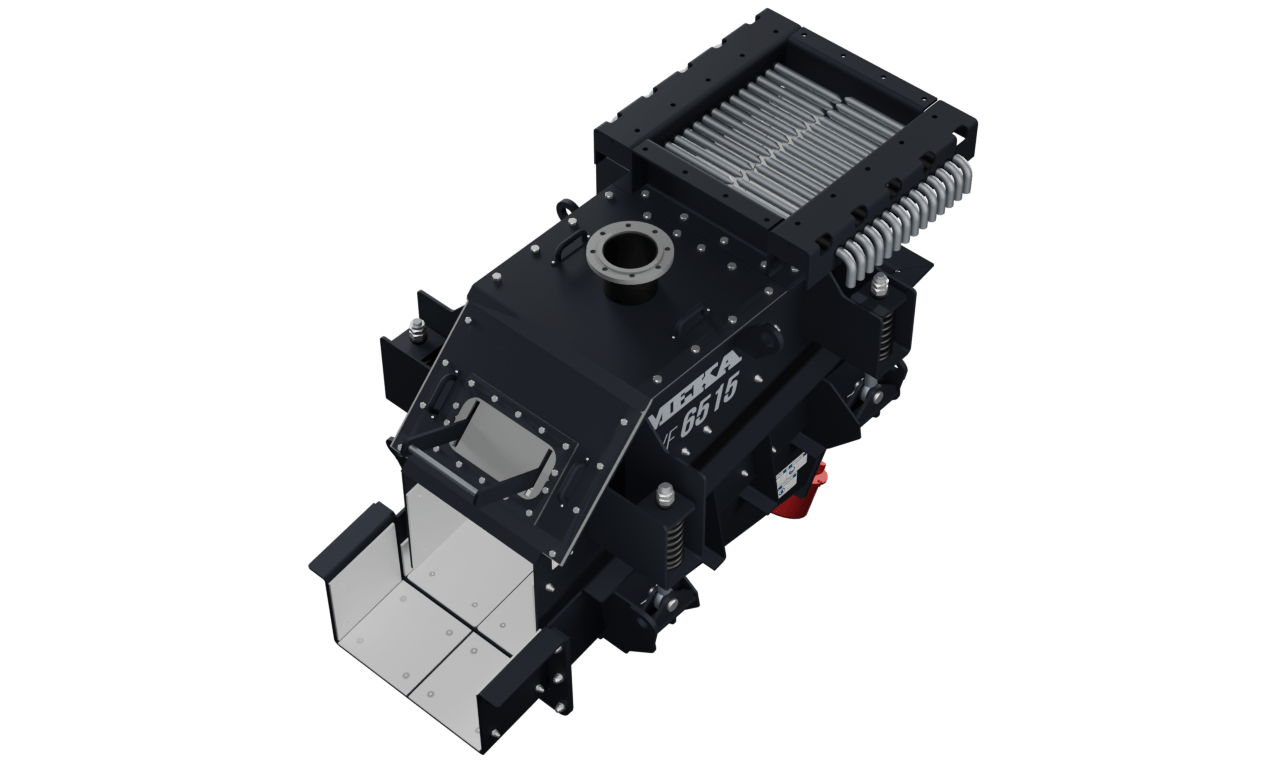

MEKA Aggregate Feeder | Heavy-Duty Aggregate, Mineral, Sand and Rock Feeder Systems

Aggregate feeders not only transfer bulk materials to screens, crushers, hoppers, bins, and other equipment but also turn your plant into a profitable investment.

Overfeeding overloads crushers, screens, and other processing equipment, leading to costly downtime and unnecessary maintenance. Inadequate material feeding reduces production capacity and increases production costs.

Inaccurate material feeding invariably increases the plant's energy consumption and reduces operating efficiency.

MEKA's range of feeders is engineered for continuous use under harsh conditions, providing high feeding capacity.

-

For feeding large, lumpy, abrasive and heavy materials during wet, sticky or frozen operations

-

In case of difficult-to-feed wet, sticky bulk, and clayey substances, ensure consistent and controlled feeding and pre-screening.

-

Separate screen unit ensuring efficient scalping and fines removal

-

Increase your earnings with high capacity feeding, especially in the secondary and tertiary stages.

-

Provide regular feeding of coarse blasted material in the most demanding applications with high wear resistance.

-

It ensures the regular feeding of fine materials, especially for aggregate production, mining and recycling.

From Experience to Perfection

Since 1987, MEKA Global has been involved in the design, manufacture, and installation of stationary and portable aggregate processing plants and concrete batching plants throughout more than 110 countries.

Learn more about us by watching the MEKA video.

Let us solve all your feeder needs!

How much do apron feeders cost?

Can I get a price quote?

Can I become a dealer for your equipment?

May I learn about your feeding equipment references in the US?

How long does it take to deliver a wobbler feeder?

How can we calculate feeder capacity?

And all your questions...

Let's move on to the next level. Contact us now by filling out the form.

Can I get a price quote?

Can I become a dealer for your equipment?

May I learn about your feeding equipment references in the US?

How long does it take to deliver a wobbler feeder?

How can we calculate feeder capacity?

And all your questions...

Let's move on to the next level. Contact us now by filling out the form.