Applications

- Ideal for recycling, demolition and volume reduction projects in constrained inner city environments,

- Demolition sites where rebars should be separated from construction debris,

- Optional 3 deck screening plant downstream from MCC plant for product sizing.

Why MEKA Construction and Demolition Waste Recycling?

WHY MEKA MCC PLANTS?

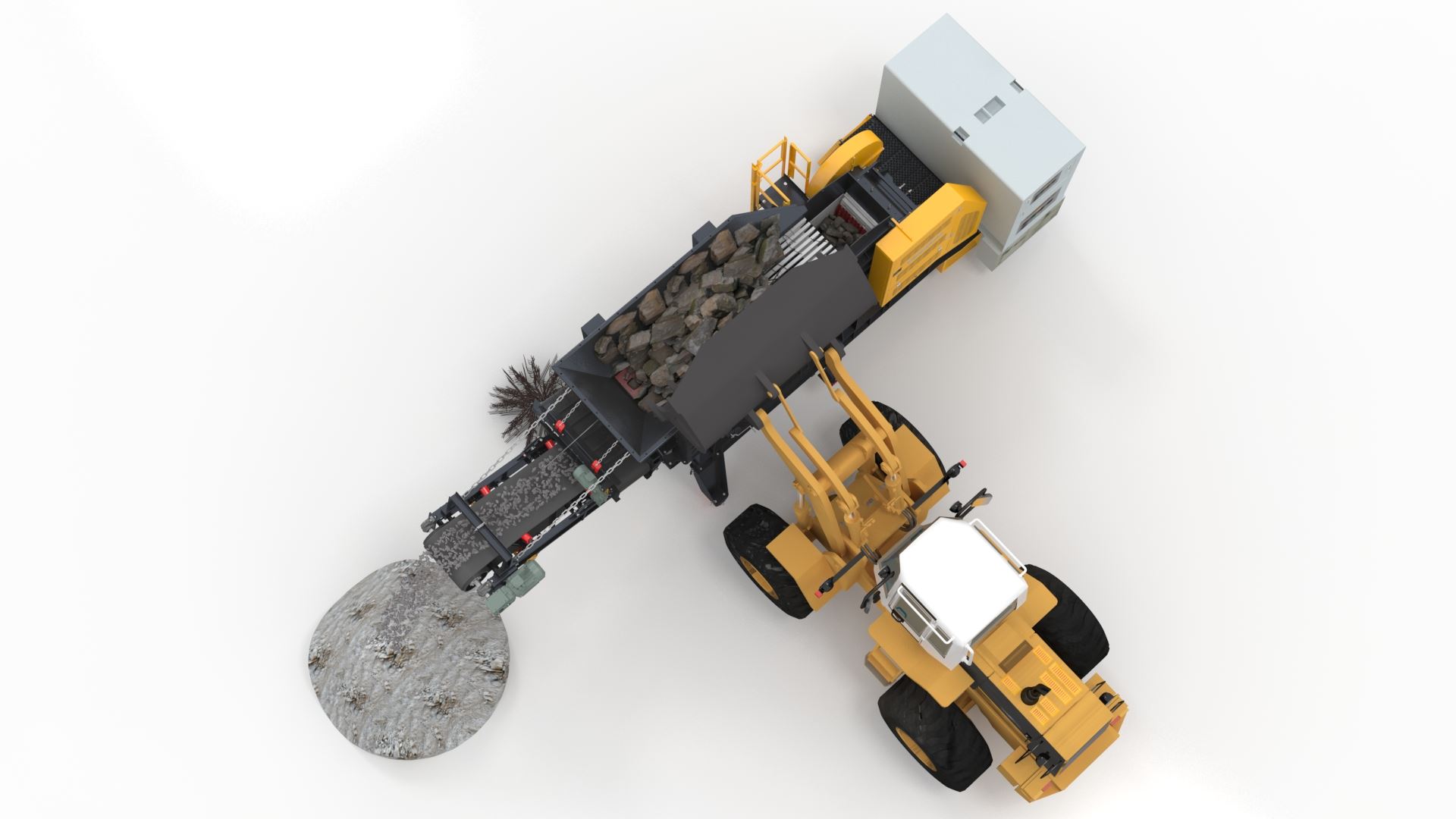

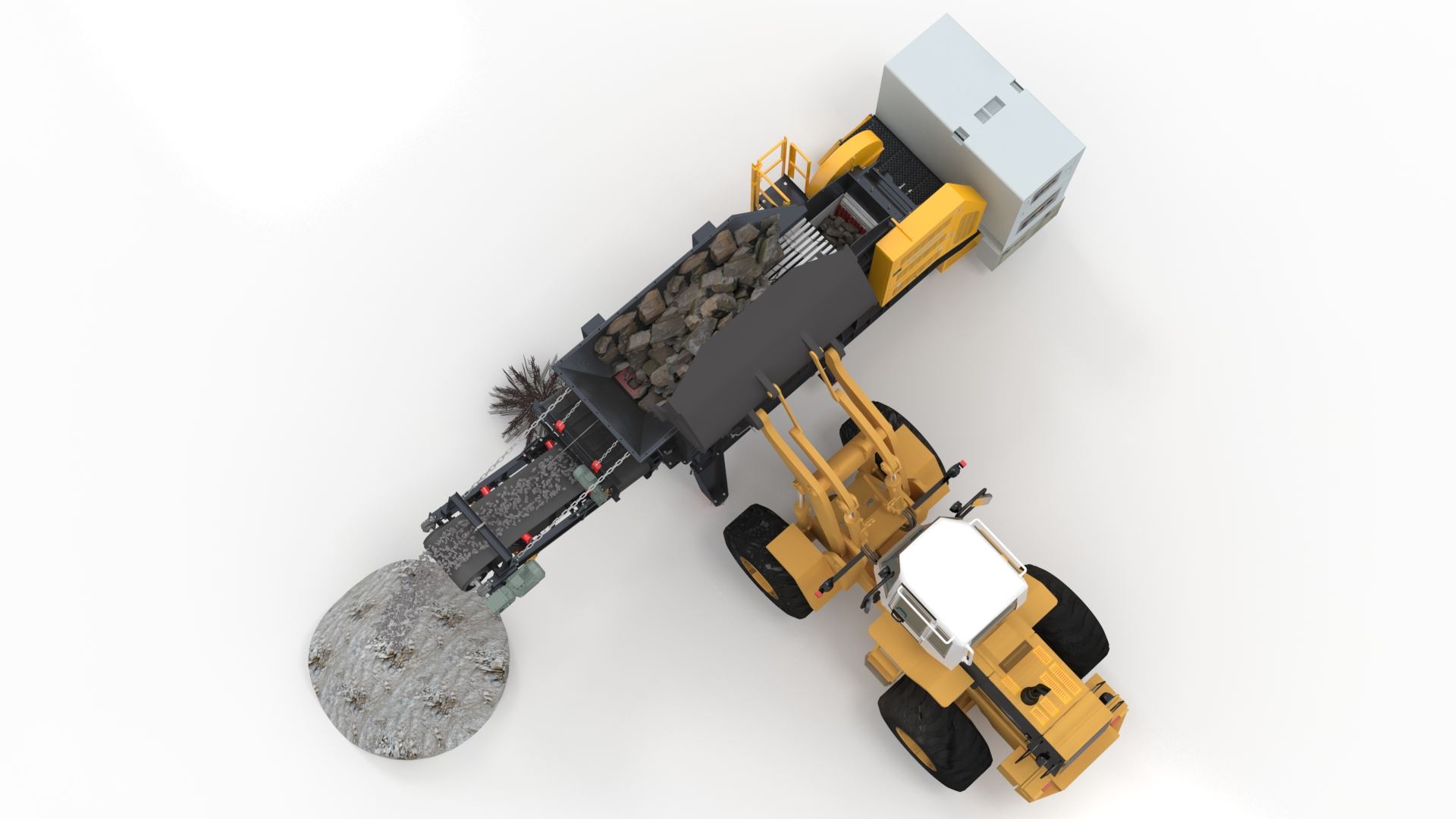

- Fully transportable hook-lift type primary crushing plant complete with a MEKA MJ Series single toggle jaw crushers,

- All models are high-capacity, extremely versatile semi-mobile crushing plants suitable for urban recycling and demolition projects,

- The under-frame members are designed to the universal industry standard for hook lift frames and when off-loaded distributes ground loadings,

- Wheel loader or excavator feed; Feed hopper can accomodate both of these without any restrictions,

- Electrical drive; MCC Plants are ready for use with an external power supply, or with an on-board diesel generator,

- Loading device for transportation on a low-bed trailer.

Construction and Demolition Waste Recycling Gallery

Construction and Demolition Waste Recycling Technical Specifications

MCC 70 |

MP 90 |

MP 110C |

|

| FEEDER | |||

| Model | MGF 6530 | MGF 0942 | MGF 1160 |

| Width | 650 mm | 900 mm | 1 100 mm |

| Length | 3 000 mm | 4 200 mm | 6 000 mm |

| Grizzly Length | 1 000 mm | 1 500 mm | 1 400 mm |

| Grizzly Gap Adjustment | 30 - 40 mm | 55 - 75 mm | 65 mm |

| Motor Power | 2 x 3.2 kW | 2 x 6.1 kW | 22 kW |

| Hopper Volume | 1.3 m³ | 8 m³ | 20 m³ |

| JAW CRUSHER | |||

| Model | MJ 70 | MJ 90 | MJ 110C |

| Feeding Opening | 700 x 400 mm | 900 x 650 mm | 1 070 x 770 mm |

| Maximum Feed Size | 320 mm | 580 mm | 730 mm |

| Capacity | up to 110 mtph | up to 200 mtph | up to 340 mtph |

| CSS Range | 30 - 100 mm | 60 - 150 mm | 75 - 210 mm |

| Motor Power | 37 kW (50 Hz) | 75 kW (50 Hz) | 110 kW (50 Hz) |

| OVERBELT MAGNETIC SEPARATOR | |||

| Magnet Dimensions | 500 x 650 mm | 750 x 880 mm | 900 x 1150 mm |

| Belt Width | 500 mm | 650 mm | 800 mm |

| Motor Power | 2.2 kW | 2.2 kW | 2.2 kW |

| DISCHARGE CONVEYOR | |||

| Belt Width | 650 mm | 800 mm | 1 200 mm |

| Length | 6 700 mm | 7 000 mm | 8 000 mm |

| Motor Power | 5.5 kW | 7.5 kW | 11 kW |

| TRANSPORT DIMENSIONS | |||

| Length | 8 192 mm | 12 000 mm | 16 210 mm |

| Width | 2 300 mm (with no generator) 2 400 mm (with generator) |

2 300 mm | 2 970 mm |

| Height | 2 844 mm | 3 700 mm | 4 150 mm |

| Weight | 13 260 kg (with no generator) 14 940 kg (with generator) |

33 000 kg | 52 000 kg |

| OPERATING DIMENSIONS | |||

| Length | 9 212 mm | 12 000 mm | 16 210 mm |

| Width | 2 620 mm (with no generator) 2 720 mm (with generator) |

3 700 mm | 4 190 mm |

| Height | 3 455 mm | 4 500 mm | 4 720 mm |

MP 90 and MP 110C are Wheel mounted plants.

Capacity figures shown apply to material weighing 1.6 tons per cubic meter, or 100 pounds per cubic foot.

Performance may vary depending on the feed gradation, feed moisture content, crushability of the material, rpm, installed power and the circuit design. Please consult MEKA for specific applications.

Capacity figures shown apply to material weighing 1.6 tons per cubic meter, or 100 pounds per cubic foot.

Performance may vary depending on the feed gradation, feed moisture content, crushability of the material, rpm, installed power and the circuit design. Please consult MEKA for specific applications.

What are Construction and Demolition Waste Recycling?

MIXED WASTE PLANTS FOR PRODUCTION OF RECYCLED CONCRETE AGGREGATE

Mixed construction debris coming to the plant as a result of classical demolition methods passes through crushing-magnetic separator-screening processes, and then the material that comes out as a product is subjected to certain separation processes.

Since its current quality for use as aggregate is lower than the desired quality, windsifters, optical separation systems and manual sorting station can be integrated into the plant to improve the quality of materials and to separate the desired materials from the mixed waste.

With full experience of equipment designing and manufacturing in CDW recycling field, MEKA has researched and developed efficient integrated recycling technologies for choice. We have a skillful engineers team to provide most suitable CDW processing solutions for our clients.

We provide solutions for centralized waste process, which can handle a large amount of mixed demolition and construction waste, with strong production capacity, high stability and powerful functions. According to your specific needs, the entire system can include feeding and pre-screening, crushing, material sorting, cleaning, aggregate optimization, dust removal, water treatment and other modules.

Mixed construction debris coming to the plant as a result of classical demolition methods passes through crushing-magnetic separator-screening processes, and then the material that comes out as a product is subjected to certain separation processes.

Since its current quality for use as aggregate is lower than the desired quality, windsifters, optical separation systems and manual sorting station can be integrated into the plant to improve the quality of materials and to separate the desired materials from the mixed waste.

With full experience of equipment designing and manufacturing in CDW recycling field, MEKA has researched and developed efficient integrated recycling technologies for choice. We have a skillful engineers team to provide most suitable CDW processing solutions for our clients.

We provide solutions for centralized waste process, which can handle a large amount of mixed demolition and construction waste, with strong production capacity, high stability and powerful functions. According to your specific needs, the entire system can include feeding and pre-screening, crushing, material sorting, cleaning, aggregate optimization, dust removal, water treatment and other modules.

Types of Construction and Demolition Waste Recycling

Recycling plants can be classified as three types ; mobile, semi-mobile and fixed plants.

How Does Construction and Demolition Waste Recycling Work?

In the mobile plant the waste material is crushed and screened with ferrous impurities extracted by magnetic separation method. The crusher is usually transported to operation site where selected suitable non-contaminated concrete or masonry waste can be processed to meet specified standards. In the case of the semi mobile plant, contaminated components are manually separated by hand with the final product also undergoing screening with the extraction of ferrous impurities achieved by the magnetic method. It is believed that the end product from the semi mobile plant has higher quality than that of the mobile plant. Whereas fixed plants are specially designed to execute the crushing, screening and purification processes, resulting with the products having the highest quality. However, certain factors are considered when setting up a fixed recycling plant namely: site and plant location, road and plant accessibility, land space availability, availability of weigh stage and availability storage space among other things.

Advantages of Using Construction and Demolition Waste Recycling

A huge portion of solid waste generated globally, constitutes of CDW composed of concrete and masonry materials disposed in landfills which ideally can be recycled and reused in the building industry in forms of blocks and slabs among other structural elements with less complexity. The conversion of this waste to wealth in various forms promotes sustainable beneficial outcomes by saving land used as disposal sites and easing the pressures on scarce natural resources while creating job opportunities for locals as well as creating avenues for small scale businesses to thrive.

Construction and Demolition Waste Recycling Processes Applications

Recycled CDW as coarse or fine aggregates can be utilized as bulk and backfill materials, sub base material in road and pavement construction, landfill liners, canal lining, fills in land reclamation and drainage projects as well as in the production of new concrete with less structural complexities. Demolition activities result in masonry and brick waste which when proper recycled are mixed with cement, mortar or lime to activate its properties and used as a new material. They are often used as building materials or in the construction of road and drainage layers or in mechanical soil stabilization as a result of its inert nature. In the case of metal waste, it is often generated from demolition activities and collected in forms of pipes, light sheets, wires and metal fittings, reinforcement bars in the concrete etc., which are easily separated by magnetic process and melted. Materials made of aluminium are easily recovered without contamination and are sold to recyclers. In cases where wood is recovered in good state as frames, windows, doors, beams, roofing members, partitions etc., they are easily cleaned up and reused. High quality waste wood members have high market value for reuse in flooring and furniture while lower quality wood waste can be recycled or in very common cases, burnt for energy recovery.