Vertical Shaft Impact Crusher - L Model

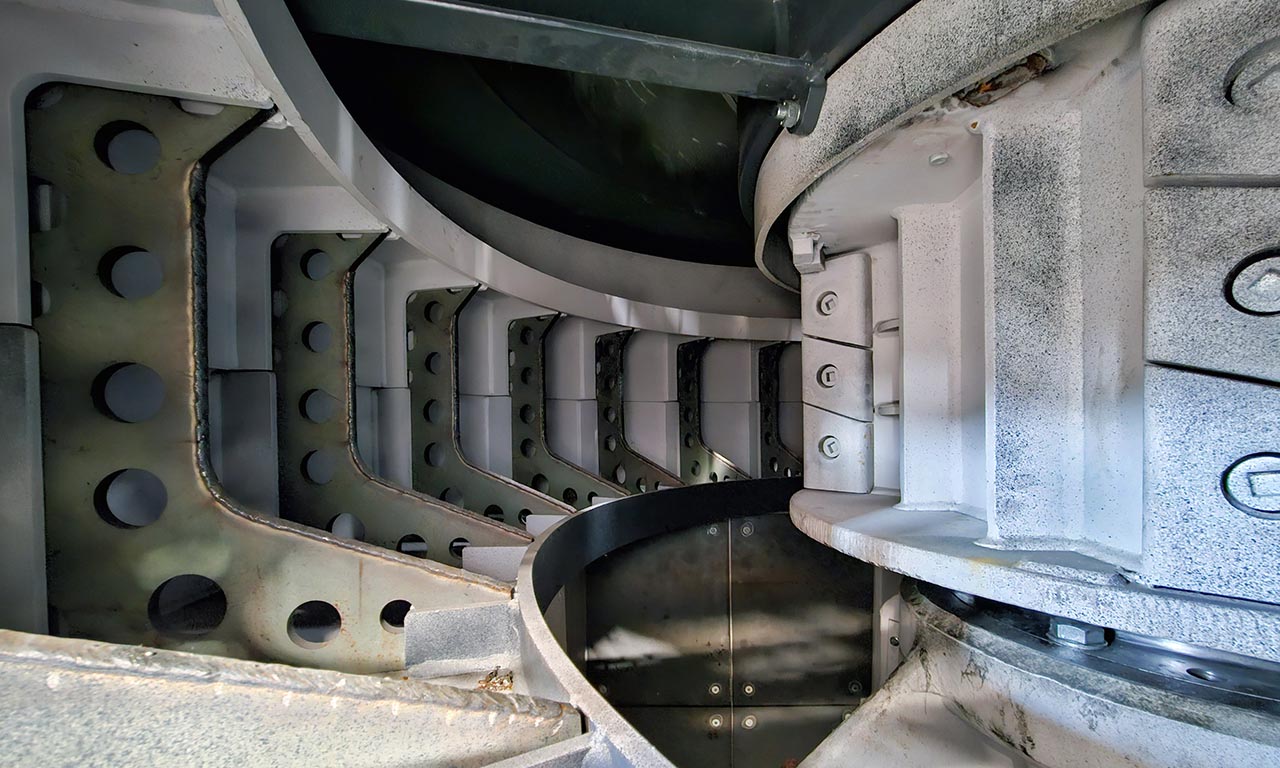

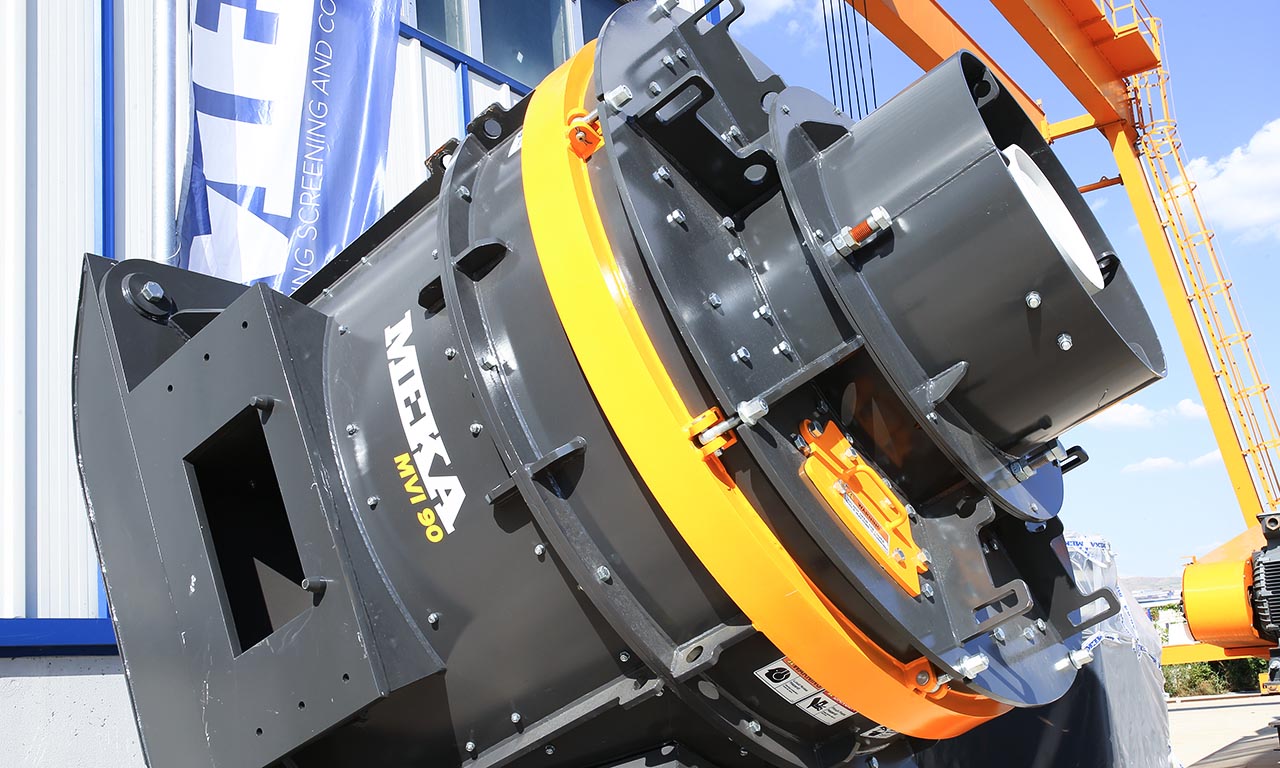

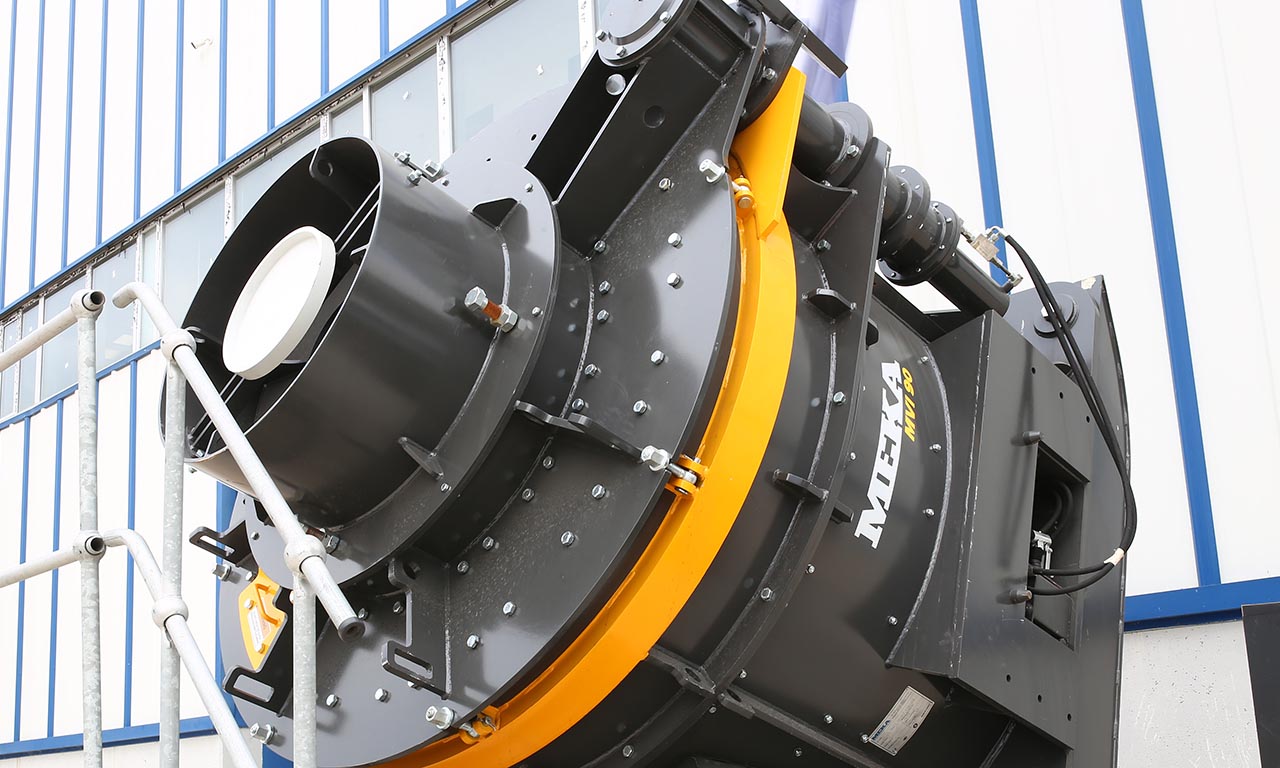

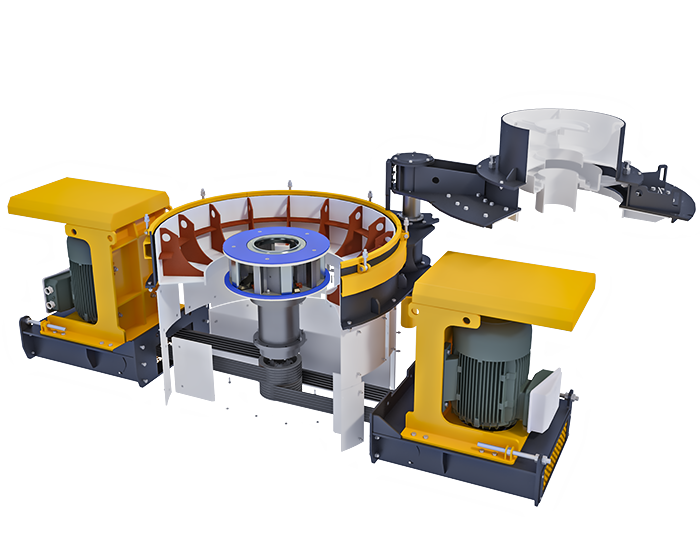

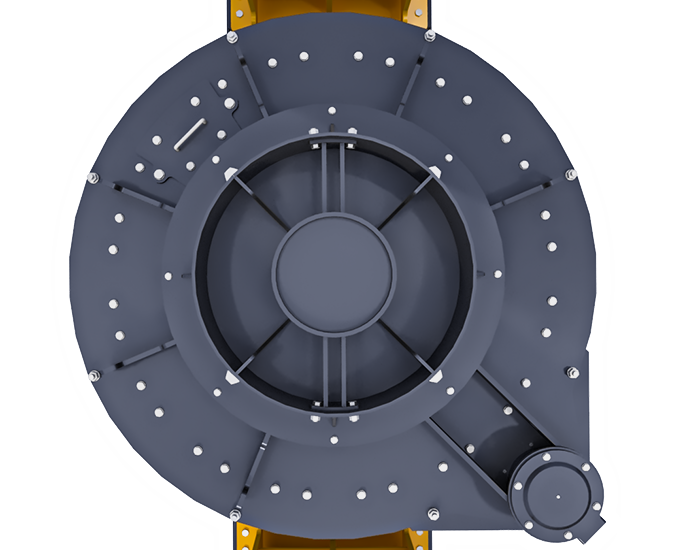

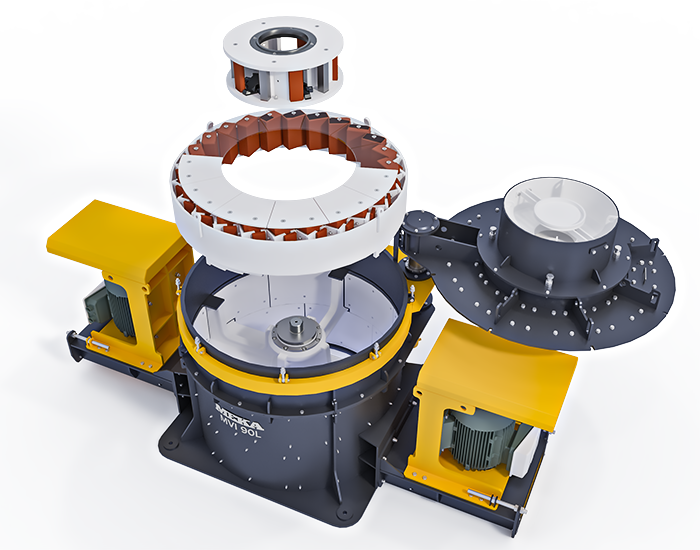

L Series vertical shaft impact crushers use high-speed rotor or heavy duty open tables. These crushers are offered in a variety of enclosed rotor or open table configurations and are convertible between three types of crushing chamber designs for maximum flexibility. Configuration options include enclosed rotor and rock shelf (ROR), enclosed rotor and anvil ring (ROS) and open table and anvil ring (SOS). This feature maximizes flexibility and allows the crusher to be configured as needed with the highest performance possible.

Applications

L Series vertical shaft impact crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial minerals.

Crushers can also be used for shaping or removal of soft stone from aggregate, crushing of cement clinker before mills and glass recycling.

Why MEKA Vertical Shaft Impact Crusher - L Model?

- Flexible crushing chamber options

- Oil lubrication system comprised of tank, pump, temperature switch, flow meter, oil cooler, oil heater and valve assembly

- Externally adjustable feed tube system with a convenient inspection door mounted on the lid, provides safe and easy inspection

- Air transfer system enables internal air circulation and reduces dust emission

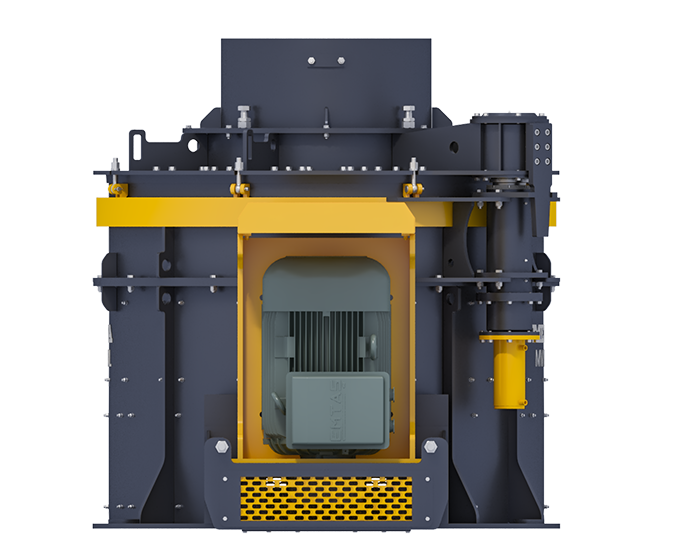

- Dual drive design reduces the radial and thrust loading on the electric motors, resulting in an extra-long service life for the motors

MEKA Vertical Shaft Impact Crusher - L Model Advantages

-

MEKA Vertical Shaft Impact Crusher - L Model Download Catalogue

Vertical Shaft Impact Crusher - L Model Technical Specifications

MVI 90L

|

MVI 90L

|

MVI 90L

|

MVI 90L

|

MVI 90L

|

MVI 90L

|

|

| Max Feed Size (mm) Max Feed Size (inch) | 50 2 | 50 2 | 50 2 | 50 2 | 75 3 | 75 3 |

| *Capacity (mtph)* *Capacity (stph) | 200 220 | 300 330 | 250 275 | 300 330 | 250 275 | 400 440 |

| Power (kW) Power (HP) | 200-250 275-340 | 2x110-160 2x150-220 | 200-250 275-340 | 2x110-160 2x150-220 | 200-250 275-340 | 2x200 2x275 |

| Speed (rpm) Speed (rpm) | 800-1700 800-1700 | 800-1700 800-1700 | 800-1600 800-1600 | 800-1600 800-1600 | 800-1400 800-1400 | 800-1400 800-1400 |

| **Weight (kg) **Weight (lbs) | 9210 20300 | 10150 22371 | 10900 24024 | 11900 26228 | 11460 25258 | 12450 27440 |

*For material weighing 1.6 t/m³ or 100 lbs/ft³. Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture content,crushability of the material, crusher rpm, installed power and the crushing circuit design.

**Weights shown do not include drive motor package, support legs, maintenance platform, inlet and outlet chutes

What is Vertical Shaft Impact Crusher - L Model?

Vertical shaft impact crusher is a tertiary or quaternary crusher and can be used in three interchangeable crushing chambers according to applications.

The high-speed rotating rotor accelerate and throw the material fed into the rotor towards the crushing chamber, which already contains rock shelf in ROR type or anvils in ROS type. In the SOS type, the material fed to the open shoe table is first crushed by applying impact with the shoes on the table, and then the material thrown against the crushing circle is crushed by hitting the anvils.

It has a wide range of uses from soft to hard, non-abrasive to abrasive materials in tertiary and quaternary stages for the production of sand and aggregates ,metal and industrial mineral processes.