Coarse Material Washer Gallery

Clean coarse aggregates in the most efficient way

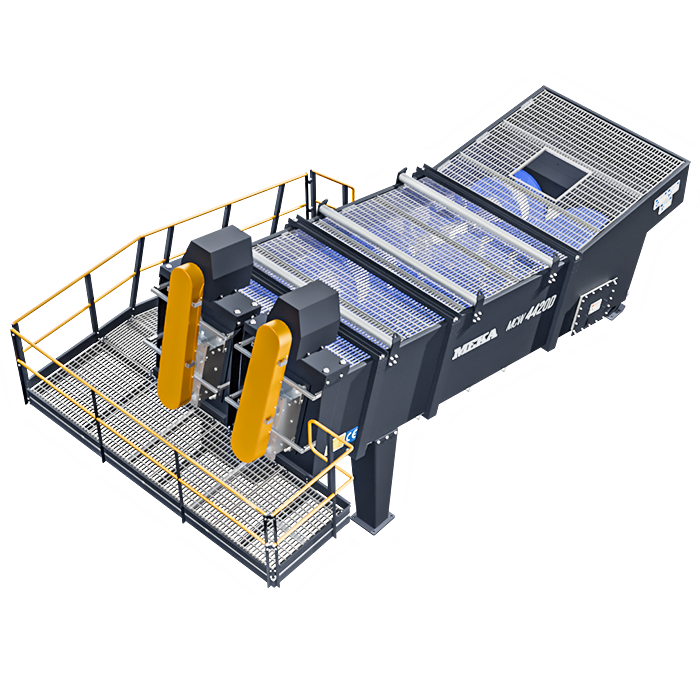

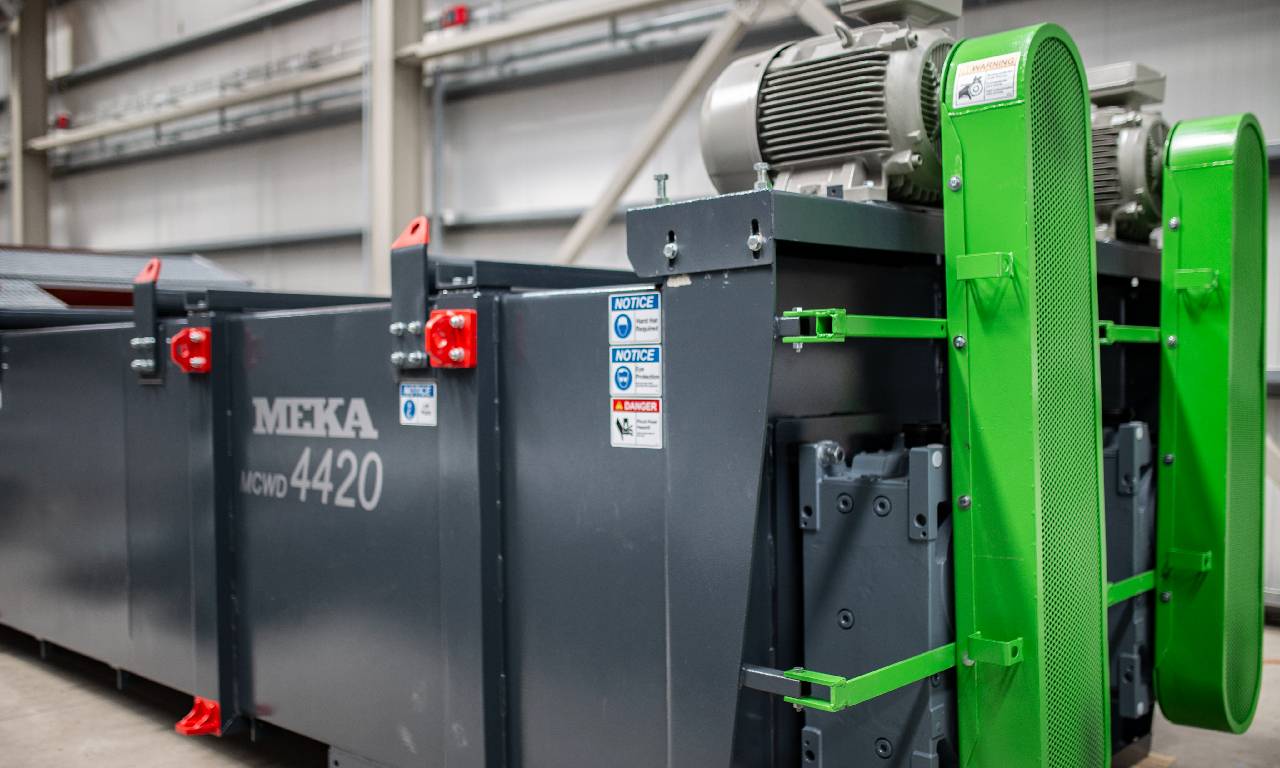

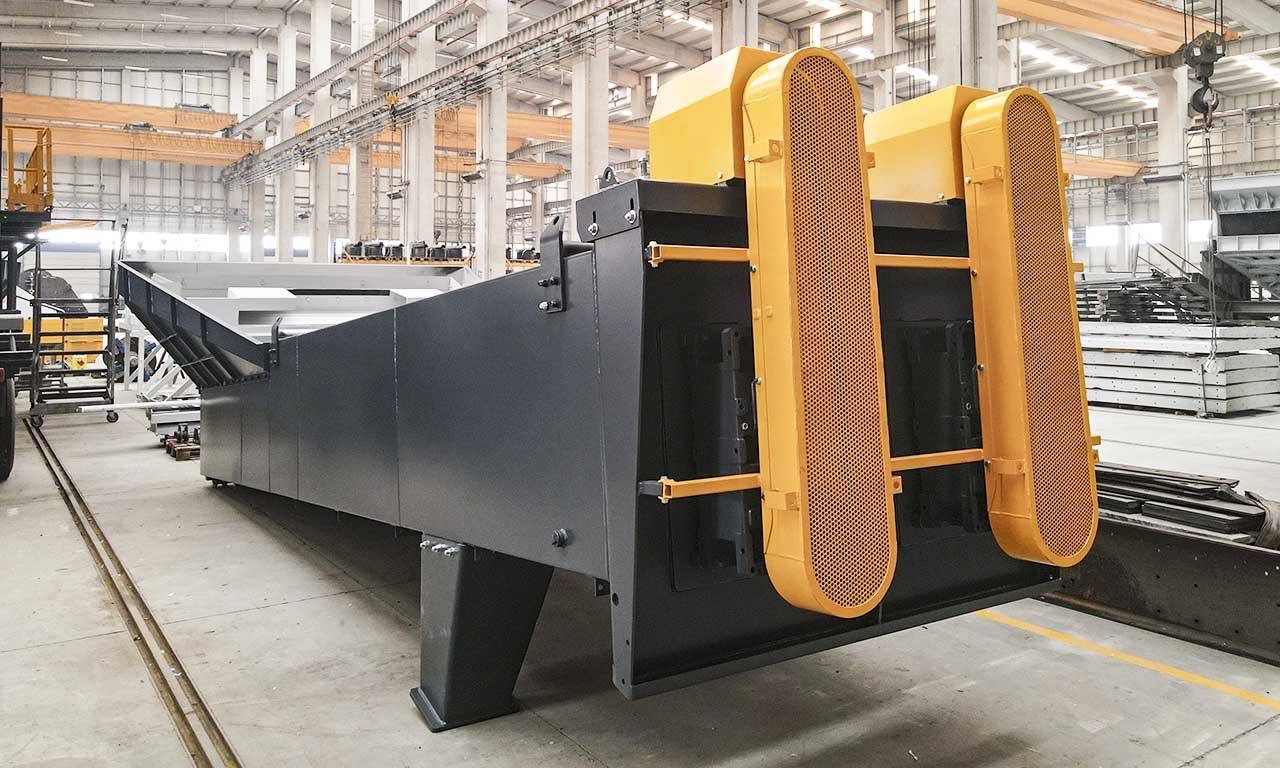

MEKA Coarse Material Washers are specifically designed to efficiently remove clay, silt, and other contaminants adhering to the surfaces of aggregates and ores. With their twin-shaft helical paddle structure, they transport material upward with a powerful scrubbing action during the washing process. At the same time, the directed water flow flushes out fine particles and eliminates remaining residues in the final rinse line.

The Ni-Hard paddles used in MCW Series Coarse Material Washers offer high wear resistance, while the custom gearbox ensures superior performance under high impact loads. The body angle is adjustable between 0° and 5°, allowing the washing time to be optimized for different applications, ensuring maximum cleanliness.

Compared to competitors, MEKA Coarse Material Washers stand out with their significantly heavier and more rigid body structure and easily replaceable wear parts, offering low maintenance costs and long service life. It is an ideal solution for removing hard and sticky clays, plastic content, and organic materials.

Applications

Washing of coarse aggregates and sand up to 75 mm coming from under-screen

Improving aggregate quality

Removing silt and clay from coarse material

Pre-washing process before dewatering

Recycling applications

Coarse Material Washer Working Principle

Coarse Material Washer Technical Specifications

MCW 3618S |

MCW 3618D |

MCW 4420S |

MCW 4420D |

|

| (Single Screw) | (Double Screw) | (Single Screw) | (Double Screw) | |

| Screw Diameter x Tube Length (mm x mm) | 928x5600 | 928x5600 | 1118x6382 | 1118x6382 |

| *Capacity (mtph) | 130-160 | 272-316 | 180-230 | 360-450 |

| Material (mm) | 0-65 | 0-65 | 0-75 | 0-75 |

| Power (kW) | 30 | 2x30 | 37 | 2x37 |

| Screw (rpm) | 16-32 | 16-32 | 13-26 | 13-26 |

| **Weight (kg) | 6500 | 10800 | 9000 | 15500 |

| Water (m3/h) | 90-135 | 160-220 | 110-170 | 200-250 |

*Capacity values are indicative only, results may vary depending on feed gradation, silt, clay content, density, amount of water used, equipment configuration and application.

**Weights shown include drive motor package, support legs, maintenance platform, inlet and outlet chutes

Would you like to request a quote or receive information about a coarse material washer?

Would you like to receive a price quote for a MEKA coarse material washer?

Do you need a coarse material washer with different options and configurations?

Do you want to become a MEKA coarse material washer dealer?

Let's move on to the next level. Contact us now by filling out the form.

What is Coarse Material Washer?

Coarse Material Washer is a washing equipment consist of shafts with paddles and spiral screw flights to provide scrubbing and agitation.

They effectively remove soluble clays in gravel or aggregate that cannot be removed by wet screening alone. They can also be used to remove floating organic waste material such as vegetation.

- Accepts sizes up to 75 mm

- Successful material cleaning with less water

- Great Achievement in dewatering

- Low operation and investment costs