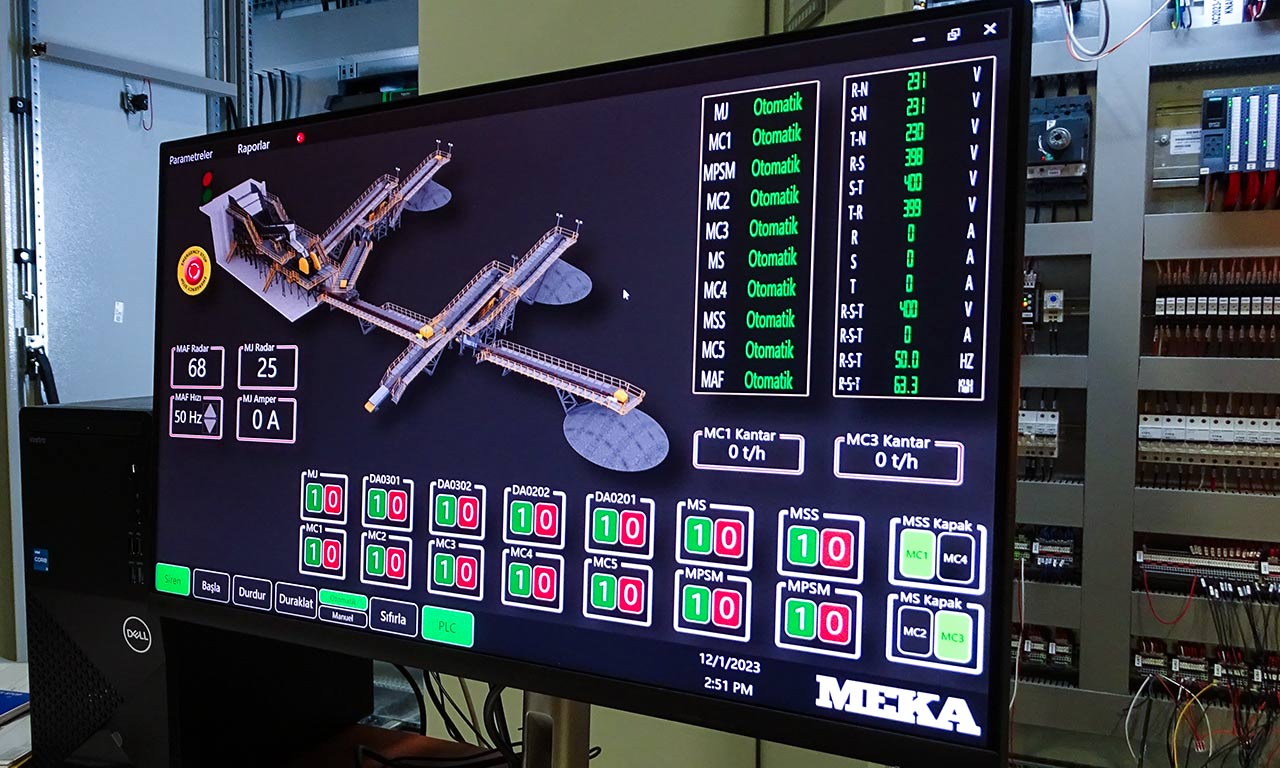

MEKA-Soft Crushing and Screening is equipped with automatic control systems that optimize the processes of crushing, screening, and separation of materials. The working principle of the system is based on the harmonious operation of mechanical and electronic components designed to provide high efficiency and durability. During the process, the crushing unit, together with screening and conveying systems, ensures the material is separated according to the appropriate size and quality. Thus, maximum efficiency is achieved with minimal intervention throughout the production process.

What is Crushing and Screening Plant Automation?

MEKASoft Crushing and Screening Plant Automation is a control system that increases productivity, minimizes manual errors and optimizes production processes in quarries and mining industry.

Application Areas

Usage Areas of Our Automation System

✅ Quarries

✅ Mining facilities

✅ Construction and infrastructure projects

✅ Stationary and mobile crushing and screening plants

✅ Quarries

✅ Mining facilities

✅ Construction and infrastructure projects

✅ Stationary and mobile crushing and screening plants

Why MEKA Automation Software?

✔ Uninterrupted production : Provides maximum efficiency with instant data analysis.

✔ Minimizes manual errors : Optimizes the production process with full automation.

✔ Energy efficiency : High performance with less energy consumption.

✔ Remote access : It provides the opportunity to manage all processes via mobile devices.

✔ Minimizes manual errors : Optimizes the production process with full automation.

✔ Energy efficiency : High performance with less energy consumption.

✔ Remote access : It provides the opportunity to manage all processes via mobile devices.

Highlights

Why Choose MEKA Automation Systems?

✔ Real-time production tracking

✔ Automatic fault detection and warning system

✔ Time savings and low maintenance costs

✔ Easy operation and user-friendly interface

✔ Real-time production tracking

✔ Automatic fault detection and warning system

✔ Time savings and low maintenance costs

✔ Easy operation and user-friendly interface

Product Features

Highlights of our Automation System

📌 Fully automatic control mechanism

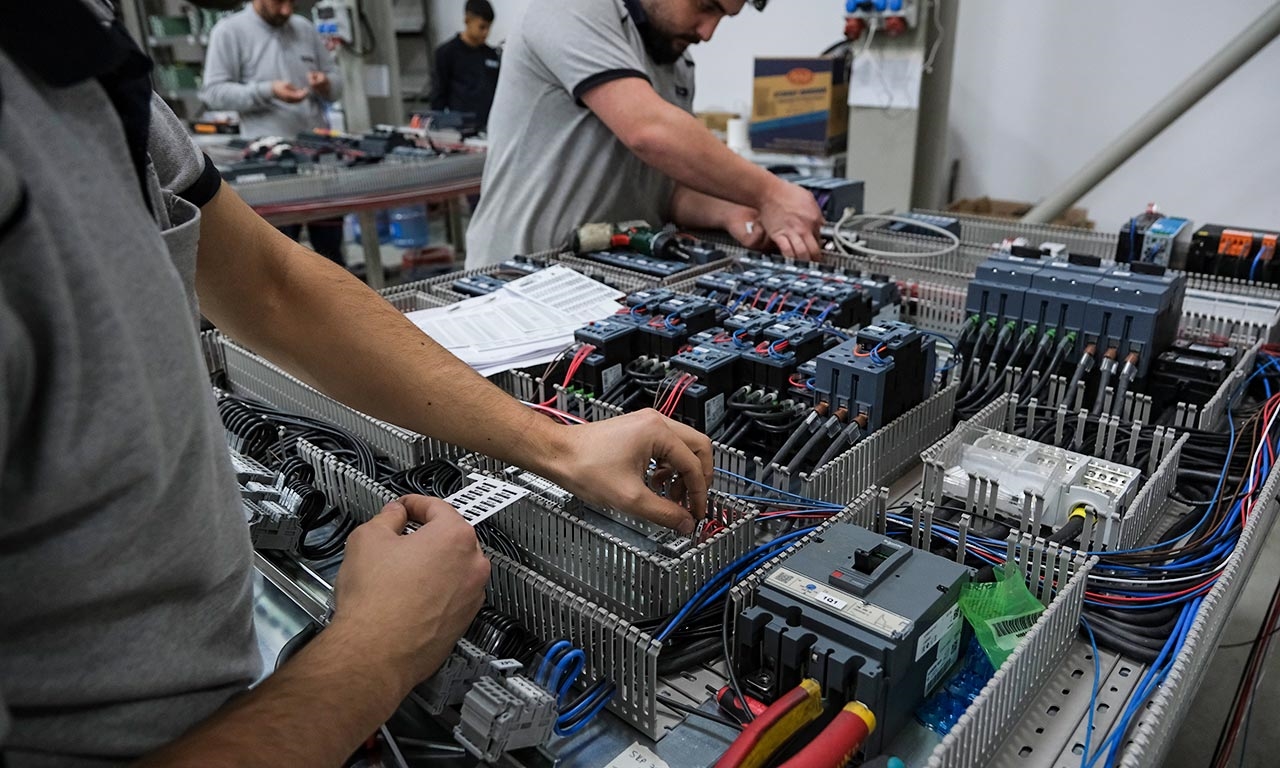

📌 Full compatibility with PLC and SCADA

📌 Remote access and mobile management

📌 Instant data analysis and reporting

📌 Integration with all crushing and screening equipment

📌 Fully automatic control mechanism

📌 Full compatibility with PLC and SCADA

📌 Remote access and mobile management

📌 Instant data analysis and reporting

📌 Integration with all crushing and screening equipment

Benefits and User Experience

Why Choose MEKA Automation Systems?

✔ Operational efficiency gains

✔ Lower labor costs

✔ Less downtime, more production

✔ Fast return on investment (ROI)

✔ Operational efficiency gains

✔ Lower labor costs

✔ Less downtime, more production

✔ Fast return on investment (ROI)

Technical Specifications

Technical Details

📍 Supported control systems (PLC, SCADA, HMI, etc.)

📍 Connection protocols (Ethernet, Modbus, Profibus, OPC UA, etc.)

📍 Supported languages and user access management

📍 System updates and integration options

📍 Supported control systems (PLC, SCADA, HMI, etc.)

📍 Connection protocols (Ethernet, Modbus, Profibus, OPC UA, etc.)

📍 Supported languages and user access management

📍 System updates and integration options

User Reviews and Success Stories

What Our Customers Say

💬 Thanks to MEKASoft, we increased our production efficiency by 30%.

📌 We ensured production continuity by minimizing downtime with our automation system.

💬 Thanks to MEKASoft, we increased our production efficiency by 30%.

📌 We ensured production continuity by minimizing downtime with our automation system.

Frequently Asked Questions (FAQ)

Frequently Asked Questions About Automation Systems

How Does the System Work?

Can I Integrate with My Existing Systems?

How Can Remote Access Be Provided?

How Is Pricing Done?

MEKA-Soft Crushing and Screening systems are modular in design and have the infrastructure to integrate with existing systems in different production plants. Specifically, automation and data transfer protocols offer flexible solutions to seamlessly integrate with various control systems. This allows the system to work in harmony with the equipment and software infrastructure of your existing facilities.

In MEKA-Soft systems, remote access technology allows operators and technical support teams to monitor the system status in real-time and intervene when necessary. Secure internet connections and password-protected access mechanisms make remote management, maintenance, and troubleshooting easy to carry out. This provides a significant advantage, especially in minimizing operational downtime.

Pricing is determined based on various factors such as the system’s capacity, configuration, and optional additional features. MEKA aims to provide the best price-performance ratio by offering customized solutions tailored to customer needs. Therefore, it is recommended to contact authorized sales representatives for detailed information and a clear price quote.