Log Washer Gallery

Engineering for heavy-duty scrubbing applications

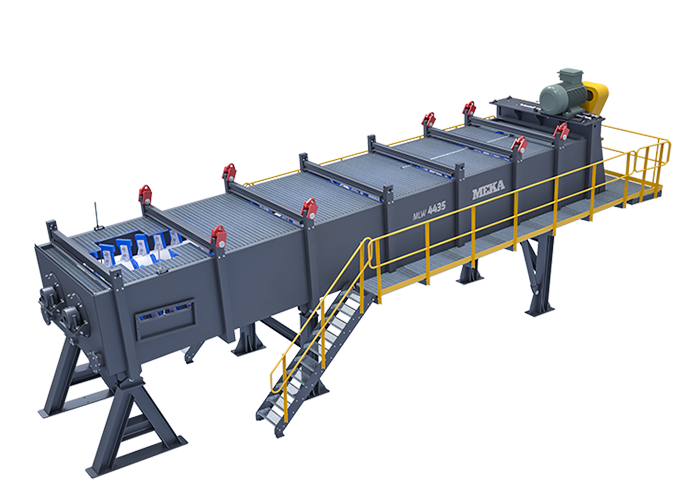

MEKA Log Washers are specifically designed to provide highly efficient scrubbing of clay, silt, and other contaminants adhering to the surfaces of aggregates and ores.

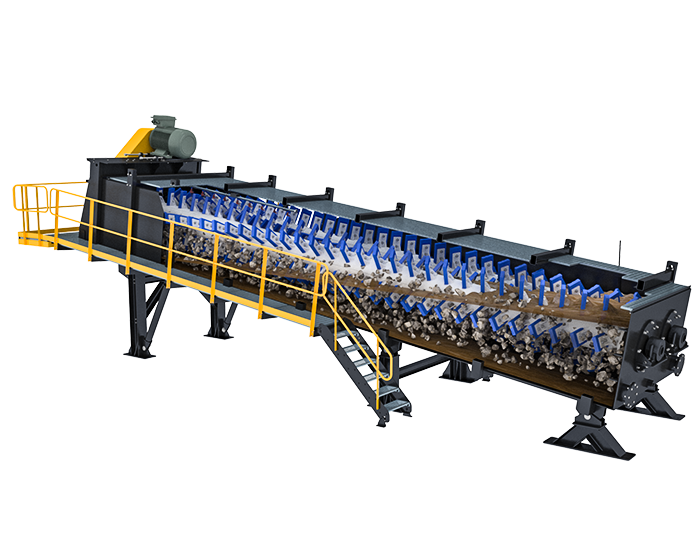

Their twin-shaft, helical paddle structure transports the material upwards with a powerful scrubbing action during the washing process. Simultaneously, the directed water flow flushes fine-grained contaminants and removes any remaining residue in the final rinse line.

The Crom Alloy paddles used in the MEKA Log Washer system offer high wear resistance, while the specialized gearbox provides superior performance against high-impact loads. Adjustable body angles between 2°-10° allow for the optimization of washing time for various applications, ensuring maximum cleaning. Compared to its competitors, the MEKA Log Washer offers low maintenance costs and a long service life with its significantly heavier and more rigid body structure and easily replaceable wear parts.

Applications

Aggregate Production

Ore Processing

Mineral Preparation in Mining and Industrial Operations

Recycling Applications

Engineering for cleaner materials

Log Washer Technical Specifications

MLW 3630 |

MLW 4430 |

MLW 4435 |

MLW 4835 |

|

| Screw Diameter (mm) | 945 | 1120 | 1120 | 1225 |

| Tube Length (mm) | 9175 | 9300 | 10820 | 10500 |

| *Capacity (mtph) | 50-125 | 75-175 | 75-175 | 110-365 |

| Material (mm) | 75 | 102 | 102 | 150 |

| Power (kW) | 2x55 | 160 | 160 | 200 |

| Screw (rpm) | 32 | 26 | 26 | 26 |

| **Weight (kg) | 26074 | 32275 | 37150 | 42185 |

| Water (m3/h) | 114 | 171 | 171 | 190 |

*Capacity values are indicative only; results may vary depending on feed gradation, silt, clay content, density, amount of water used, equipment configuration, and application.

** Weights shown include drive motor package, support legs, maintenance platform, inlet, and outlet chutes.

If you require a log washer with varying capacities and features, please get in touch with us, and we will be happy to provide a suitable solution.

Would you like to request a quote or receive information about a log washer?

Would you like to receive a price quote for a MEKA log washer?

Do you need a log washer with different options and configurations?

Do you want to become a MEKA log washer dealer?

Let's move on to the next level. Contact us now by filling out the form.

What is Log Washer?

Log Washer is a washing equipment consisting of two rotating paddle shafts to provide material-on-material scrubbing. Log Washers are used to remove tough, plastic clays in a variety of material processing applications.

This process helps to dislodge and remove contaminants like clay, mud, and organic matter from the coarse material. As the coarser materials move through the log washer to be discharged, lighter materials like clay and sand are carried away with the water flow back.

Can be adopted according to feed material specifications. Possibility of increasing the quality of the washed product. Possibility of rinsing the material before discharge.