Simply fill out the form to review our comprehensive catalog of product solutions for crushing, screening, and mining equipment.

Applications

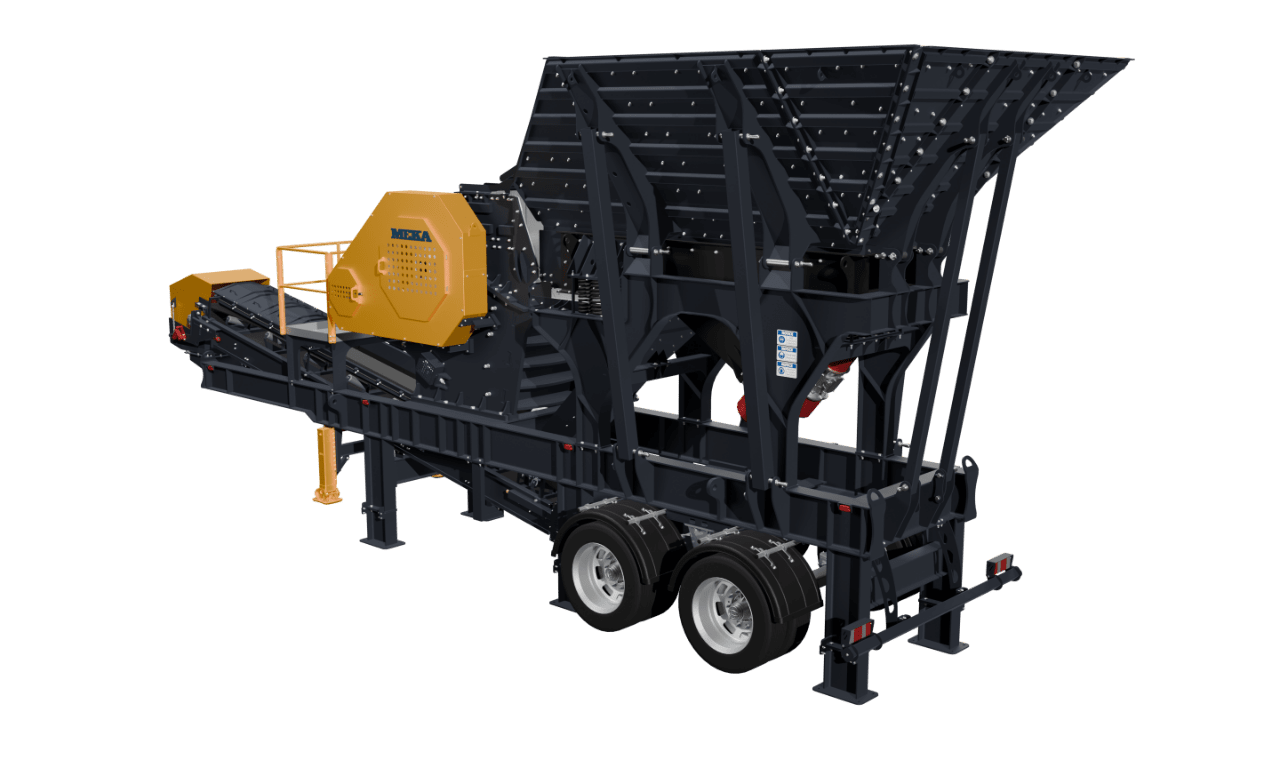

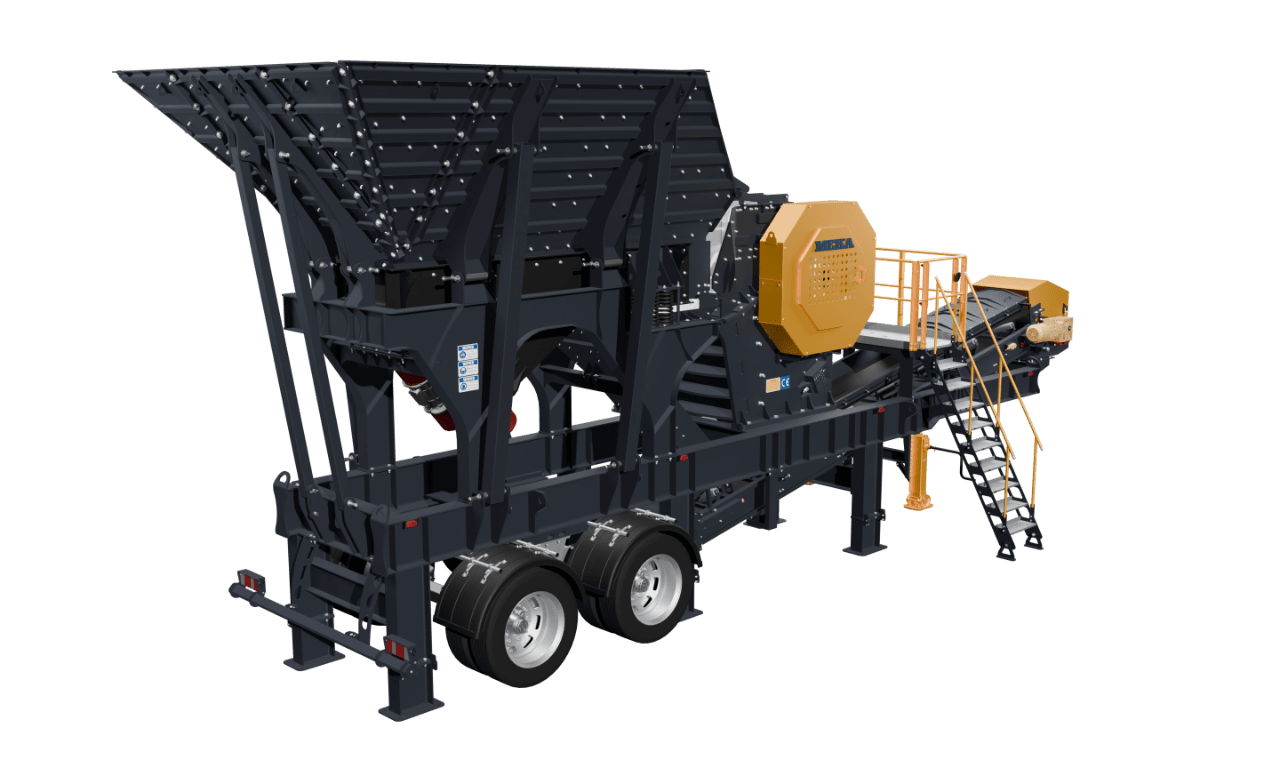

Suitable for crushing hard and soft rock, such as granite, basalt, limestone, and as well recycled materials, portable jaw crushers are the optimal choice if you want to move the crushing plant from one site to another periodically.

They are easily transportable between production sites and often utilized in aggregates production and recycling applications

Why MEKA Portable Jaw Crushers?

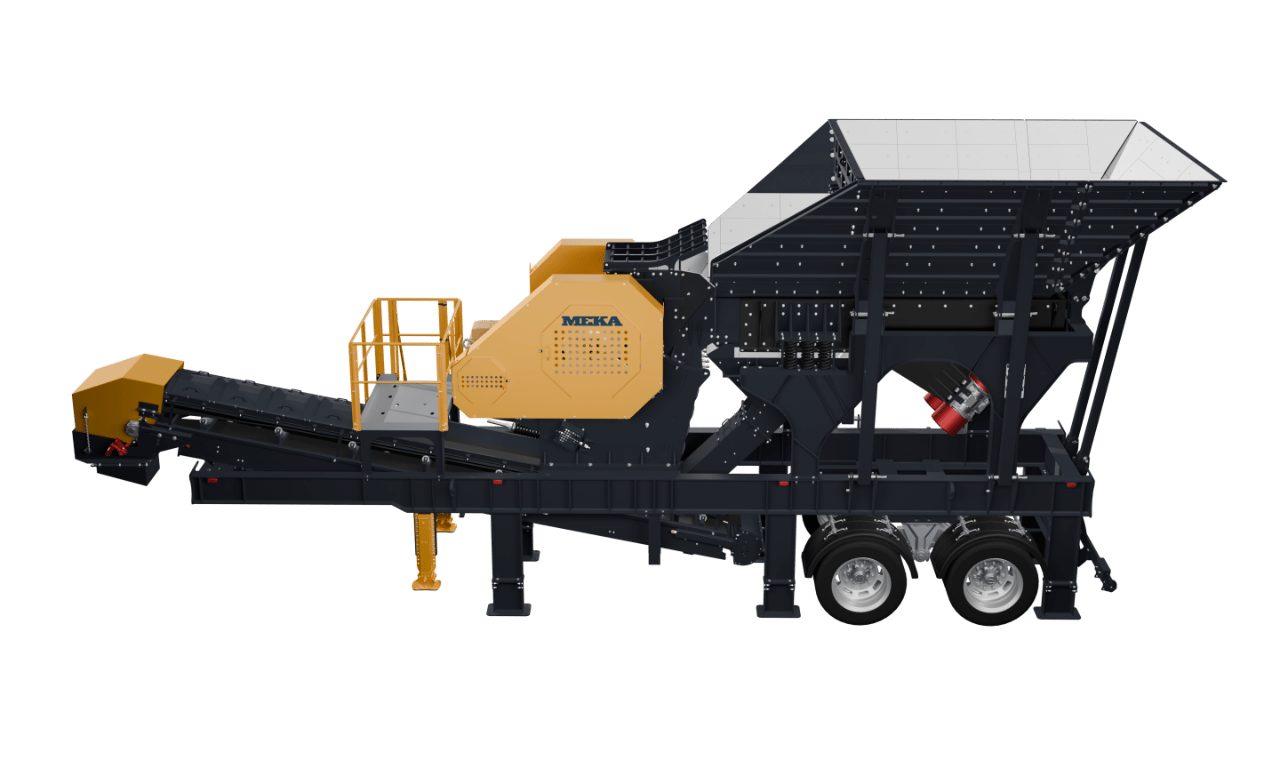

Durability : Robust heavy duty chassis frame which is fully assembled on a single trailer and mounted on double or triple axle bogies.

Effective design : The simple, yet effective design includes many benefits for quick set-up and ease of maintenance, resulting in more uptime and higher productivity.

Eco friendly : Low emissions due to electrical operation, minimizing environmental impact

Self contained electrical switchgear cabinet mounted on the semi-trailer, with controls for feeder, crusher and discharge belt conveyor,

Electrical switchgear cabinet can be located on the ground during operation,

2” / 3 ½” King-pin, double or triple-axle bogie with air-brakes, ABS and travel lights, mudflaps.

Portable Jaw Crushers Gallery

Portable Jaw Crushers Technical Specifications

MP 110C |

|

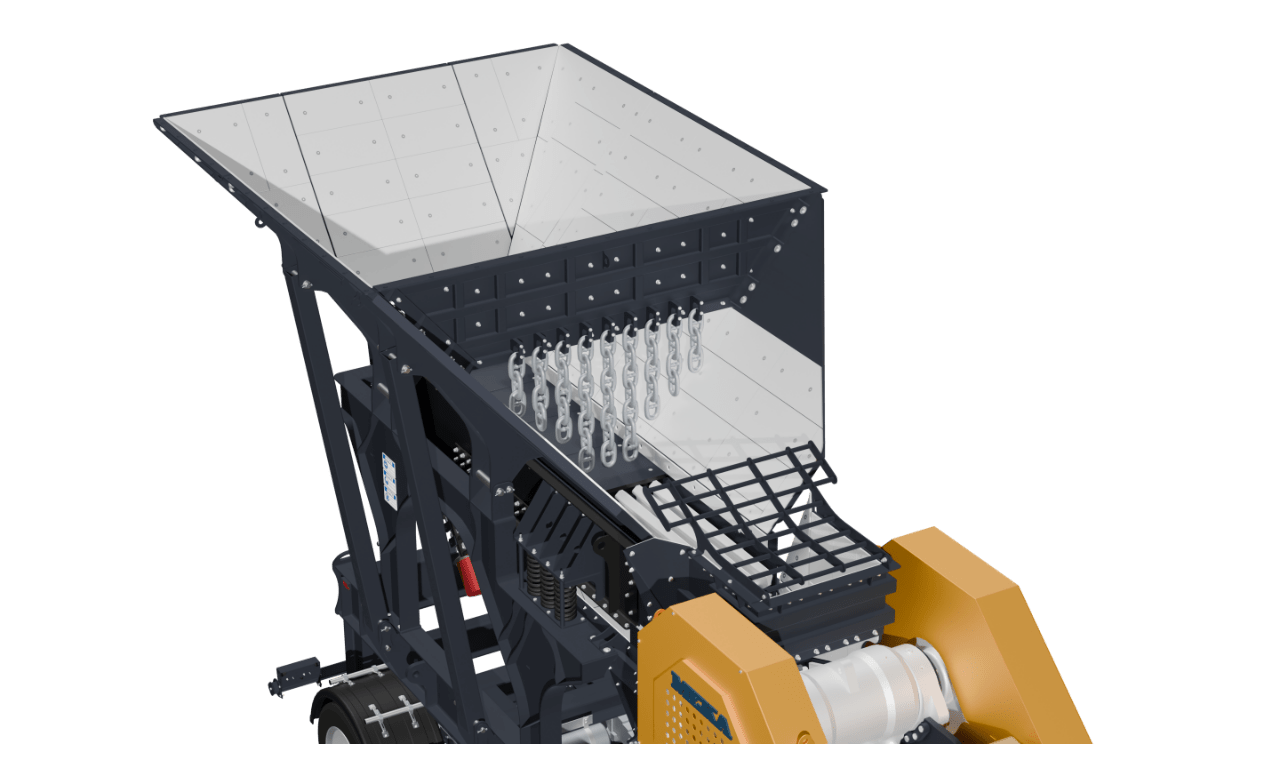

| Model | MGF 1160 |

| Width | 1.1 m |

| Length | 6 m |

| Grizzly Length | 1.4 m |

| Grizzly Gap Adjustment | 65 mm |

| Motor Power | 22 kW |

| Hopper Volume | 6.7 m3 / 20 m3 |

| Model | MJ 110C |

| Feeding Opening | 1,070 x 770 mm |

| *Capacity | up to 340 mtph |

| CSS Range | 75 - 210 mm |

| Motor Power | 110 kW (50 Hz) |

| Model | MC 1200X8000P |

| Belt Width | 1200 mm |

| Length | 8 m |

| Motor Power | 11 kW |

| Model | MC 650X1850P |

| Belt Width | 650 mm |

| Length | 1850 mm |

| Motor Power | 4 kW |

| Model | MC 800X1990P |

| Magnet Dimensions | 900x1150 mm |

| Belt Width | 800 mm |

| Length | 1990 mm |

| Motor Power | 2.2 kW |

| Model | MC 800X1990P |

| Length | 16.21 m |

| Width | 2.97 m |

| Height | 4.15 m |

| Weight | 52,000 kg |

| Model | MC 800X1990P |

| Length | 16.21 m |

| Width | 4.19 m |

| Height | 4.72 m |

*Capacity figures shown apply to material weighing 1.6 tons per cubic meter, or 100 pounds per cubic foot. Performance may vary depending on the feed gradation, feed moisture content, crushability of the material, rpm, installed power and the circuit design. Please consult MEKA for specific applications.

What is Portable Jaw Crusher?

The Portable Jaw Crusher is a portable unit which consist of feed hopper, grizzly feeder, jaw crusher and discharge conveyor on the trailer chassis. One deck screen can be installed to grizzly feeder as an option to remove the fine material. It is used in a wide range of different primary applications such as quarry, gravel pit, mining or recycling for size reduction.

Compact design: Equipment ready to work for primary stage crushing on a single chassis

Ready for operation : Can be commissioned and started up quickly

No concrete works: No need for much concrete and site preparation Quick and easy site change for another project