Simply fill out the form to review our comprehensive catalog of product solutions for crushing, screening, and mining equipment.

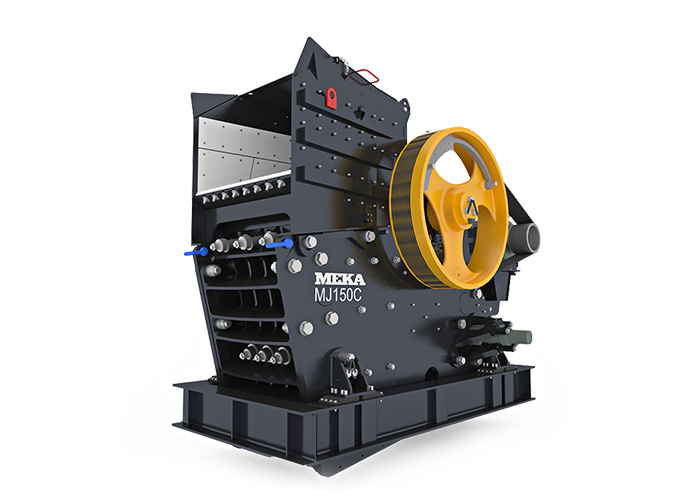

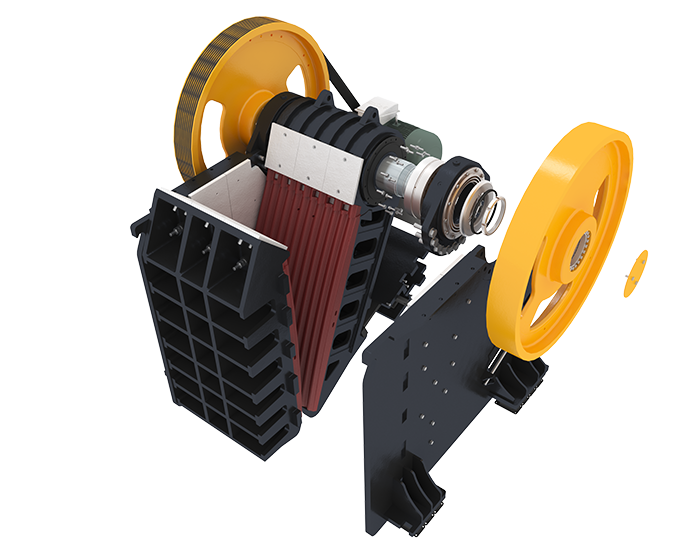

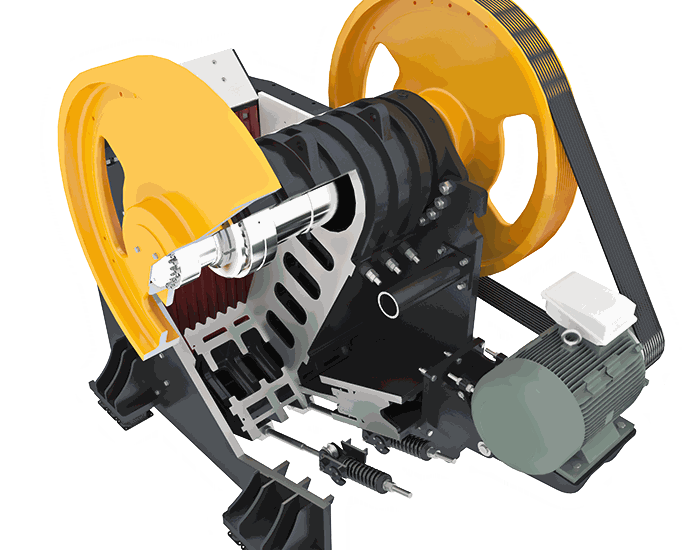

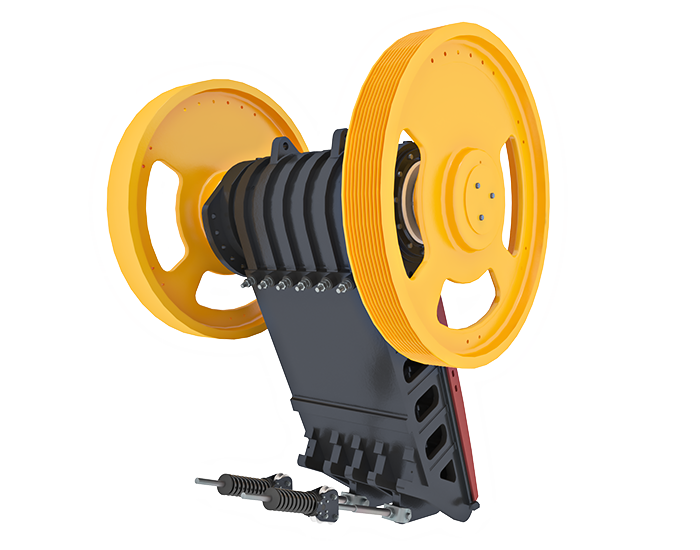

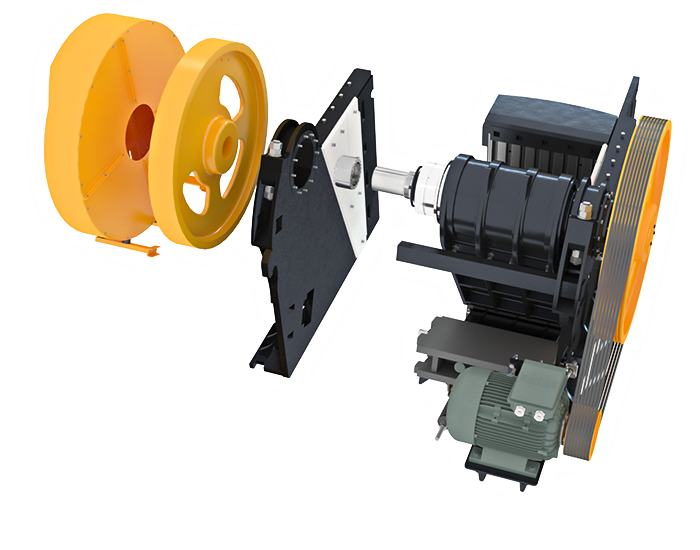

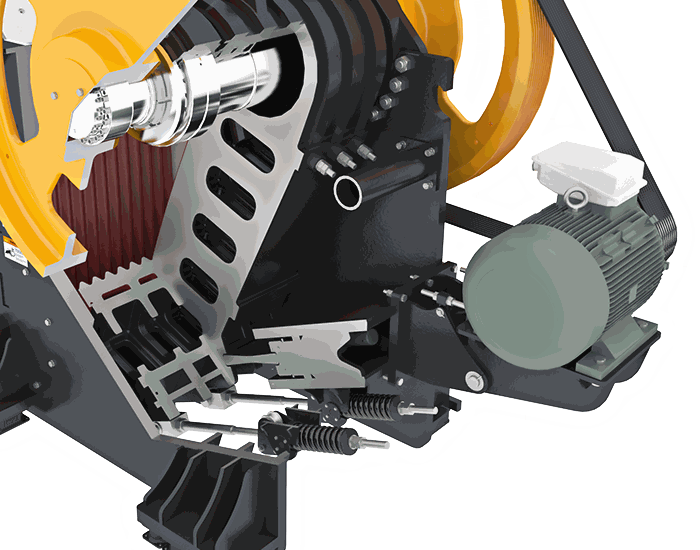

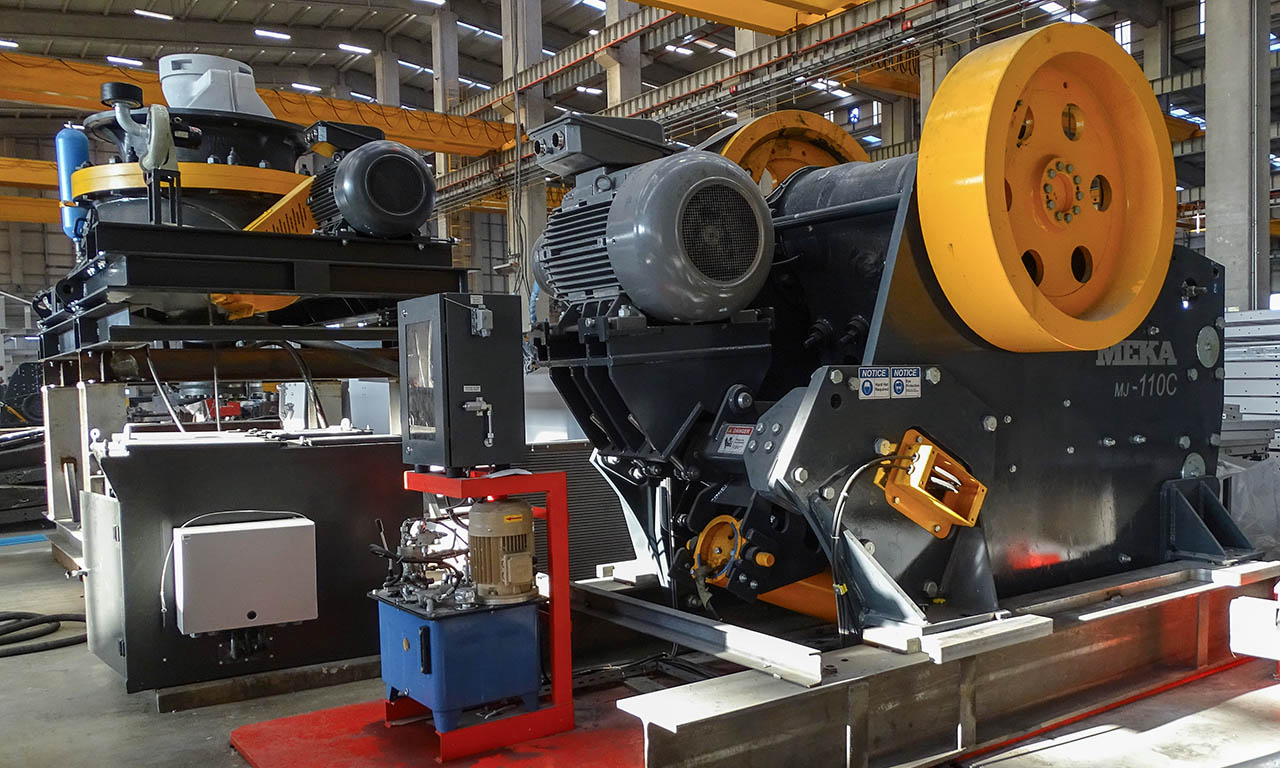

Two different designs of jaw crushers are also produced, being single or double toggle depending on the movement system of the jaw. Single toggle jaw crushers are the most common type, double toggle jaw crushers are for crushing of extremely hard materials.