Simply fill out the form to review our comprehensive catalog of product solutions for crushing, screening, and mining equipment.

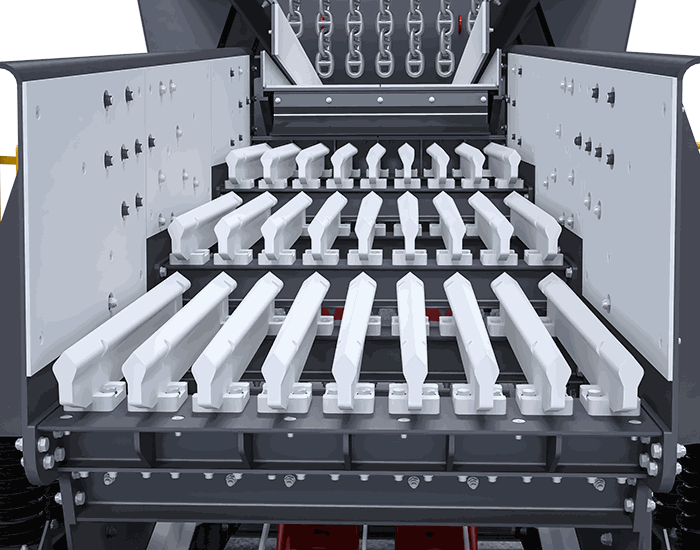

Pan Feeders with Grizzly Scalper Gallery

Regular feeding with extra durable MEKA Grizzly Vibrating Feeders for high process capacity

MEKA MSF Series Grizzly Pan Feeders (combining MPF pan feeders and MSS screens) are installed at the primary bunker outlet to ensure consistent feeding. They guarantee continuous material flow to primary crushers, enhancing overall plant efficiency. With heat-treated drive consoles, heavy-duty chassis, wear-resistant liners on the base and sides, and high-quality vibro motors, MEKA feeders deliver maximum efficiency, reliable feeding, and long-term operation with minimal downtime.

Applications

Grizzly vibrating feeders are versatile and can be used for feeding large rocks, separating smaller particles, or handling moist and sticky materials, ensuring efficient feeding for crushers in demanding conditions.

Looking for a grizzly vibrating feeder that delivers superior performance under the toughest conditions?

Pan Feeders with Grizzly Scalper Technical Specifications

MSF 0965 |

MSF 1176 |

MSF 1390 |

MSF 1690 |

MSF 1890 |

|

| W x L / Feeder (mm x mm) | 900x3500 | 1100x4600 | 1300x5000 | 1600x5000 | 1800x5000 |

| Drive @50hz (kW) | 2x5.5 | 2x7.5 | 2x12 | 2x13.9 | 2x13.9 |

| Drive @60hz (kW) | 2x4.2 | 2x8 | 2x11 | 2x16.5 | 2x16.5 |

| Exciter Drive (kW) | - | 18.5 | 22 | 30 | 37 |

| Exciter Drive (Speed) | - | 500-800 | 500-800 | 500-800 | 500-800 |

| W x L / Scalper (mm) | 1000x3000 | 1200x3000 | 1400x4000 | 1900x4000 | 1900x4000 |

| Power @50hz (kW) | 2x6.1 | 2x7.5 | 2x12 | 2x22.6 | 2x22.6 |

| Power @60hz (kW) | 2x7.5 | 2x10.6 | 2x16.5 | 2x30 | 2x30 |

| *Capacity (mtph) | 250-400 | 400-640 | 500-825 | 650-1000 | 700-1120 |

| Maximum Feed Size (mm) | 600 | 800 | 900 | 1200 | 1350 |

*At specified inclination and for material weighing 1.6 t/m³ or 100 lbs/ft³.Capacity values are indicative only and depend not only on feeder size but also on feeder inclination, feed gradation, etc.

Would you like to request a quote or receive information about a pan feeder with grizzly scalper?

Would you like to receive a price quote for a MEKA pan feeder with grizzly scalper?

Do you need a pan feeder with grizzly scalper with different options and configurations?

Do you want to become a MEKA pan feeder with grizzly scalper dealer?

Let's move on to the next level. Contact us now by filling out the form.

What are Pan Feeders with Grizzly Scalper?

Pan Feeders are also known as vibratory feeders and their motion type is linear.They fulfill the function of constant feeding of the material. Material moves forward on a pan with wear-resistant liners.

Scalpers resist to plugging and blinding and ensure that the material that will bypass the crusher is scalped and the oversize is fed to the crusher.