A mobile aggregate feeding conveyor transports aggregate materials to silos, bunkers, or mixing units. By maintaining a steady and uniform feed rate, it ensures continuity and efficiency in the concrete production process.

Mobile Aggregate Feeding Conveyor

Due to the structure and design of mobile bin height is quite high. In order to reduce the cost for building a one-side or two-side feeding ramp we have developed a mobile feeding system which allows easy feeding without any extra costs for foundation or ramp. The system can either be supplied on a wheel basis for mobility or without wheel base for container transport.

WHEELED BASE

Wheeled base allows easy transportation with a single trailer truck. It can be detached for container transport as well.

FOLDING CONVEYOR

Folding design allows fast setup and dismantling.

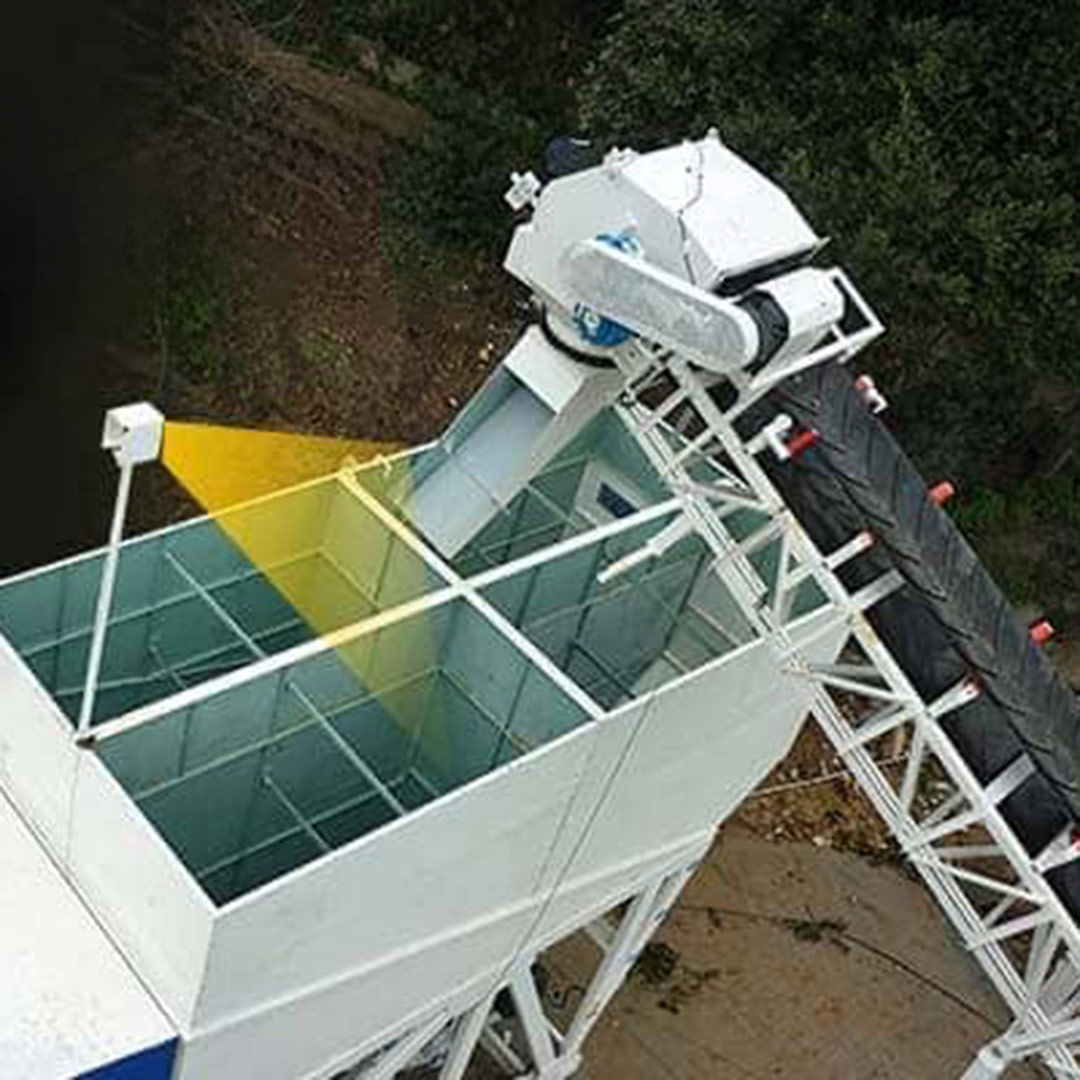

ROTATING DISCHARGE CHUTE

The are being distributed with the help of a rotating chute.

CAMERA SYSTEM

Camera system allows exact control for the rotating discharge chute which ensures better distribution and eliminates contamination of materials.

-

Mobile Aggregate Feeding Conveyor Downloadable Files

Mobile Aggregate Feeding Conveyor Optional Features

Mobile aggregate feeding conveyor is a portable conveying system designed to transport aggregates (such as sand, gravel, and stone) to concrete batching plants or other processing units. The conveyor ensures a fast, efficient, and continuous material supply.

Due to its mobility, it can be easily transported and installed at different construction sites or production facilities. It is widely used in concrete plants, asphalt plants, quarries, and recycling facilities.

Portability: Easily relocatable for site or plant changes.

Time Efficiency: Speeds up the aggregate feeding process, optimizing production.

Reduced Labor Costs: Minimizes the need for manual handling, lowering labor expenses.

Continuous Feeding: Ensures a consistent and uniform material flow.

Versatility: Suitable for transporting sand, gravel, stones, coal, and recycled materials.

Mobile aggregate feeding conveyors typically have capacities ranging from 10 m³/hour to 500 m³/hour. Their length and width vary depending on the application and material type.

Ready-mix concrete plants → For the consistent feeding of aggregates into the mixer.

Asphalt production plants → For transferring materials into mixing units.

Mining and quarries → For transporting ores and stone materials.

Recycling facilities → For feeding materials into the reprocessing line.

Regularly inspect and clean conveyor belts.

<