Simply fill out the form to review our comprehensive catalog of product solutions for crushing, screening, and mining equipment.

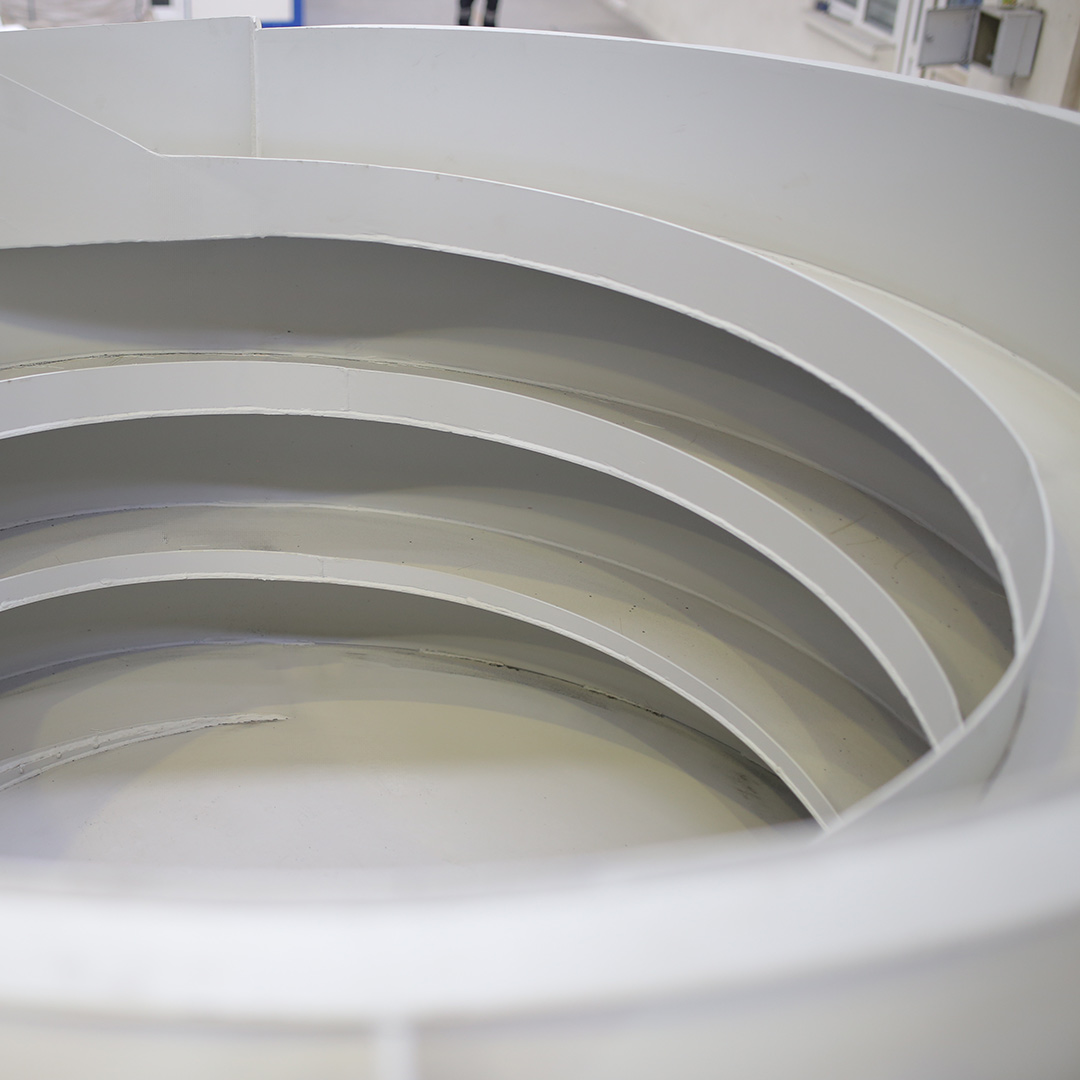

A fiber dosing system ensures that steel or synthetic fibers are added to the concrete mix in the desired amount and in a homogeneous manner. This increases the crack resistance of the concrete and results in a more durable structure. Compared to manual dosing, it operates with higher precision, preventing material waste and speeding up processes.