DISCOVER MORE

Briefly K200

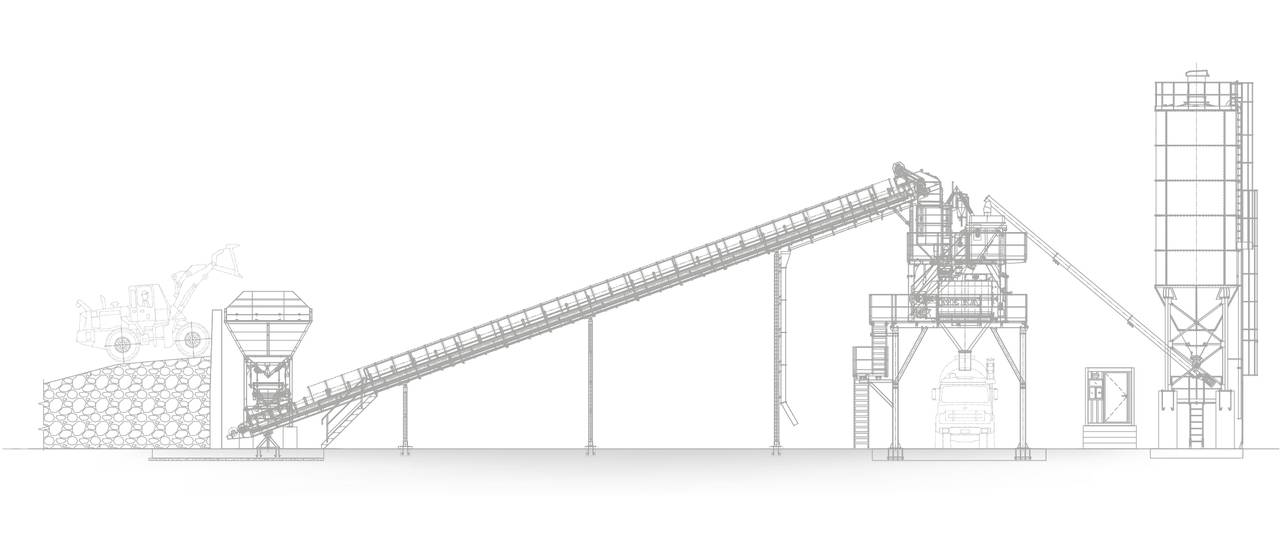

The K200 Stationary Concrete Batching Plant stands out as a class leader in productivity and durability, offering unmatched flexibility to produce ready-mixed concrete, roller compacted concrete (RCC)-road concrete, or precast concrete. It is fully customizable with various options to meet diverse business requirements.

Equipped with a powerful 5.0 m³ capacity MEKA twin-shaft mixer, the K200 delivers extraordinary productivity and a significant business advantage. Designed to accommodate mass production, it can be configured with single or double concrete pouring chutes. The plant's robust construction enables it to handle even the most demanding conditions with ease.

The K200 comes with a standard 5x25 m³ aggregate bunker, with an option for a 5x35 m³ bunker, offering a range of options to suit your production needs. Each compartment of the bunker is equipped with two independently controlled pneumatic discharge gates, enhancing production speed and efficiency.

MEKA's R&D engineers have ensured that the K200 features a more robust and stable chassis than its competitors. This design not only provides superior durability but also minimizes vibration in the weighing scales, ensuring precise weighing and compliance with the concrete recipe for maximum production power.

K200 Stationary Concrete Batching Plant Components

K200 Stationary Concrete Batching Plant Gallery

Optional Features For All MEKA Concrete Batching Plants

Your concrete batching plant investment purpose and your expectations from the plant may vary different.

Whether you are a ready-mixed concrete producer, a contractor or a manufacturer of precast building elements, we have a very strong R&D team and international experience since 1987 to design and manufacture the most suitable batching plant for your needs.

Here are some of our customization options. Our technical sales team can support you in assiting the appropriate layout and equipment to optimize your productivity and business.

DISCOVER MORE

DISCOVER MORE