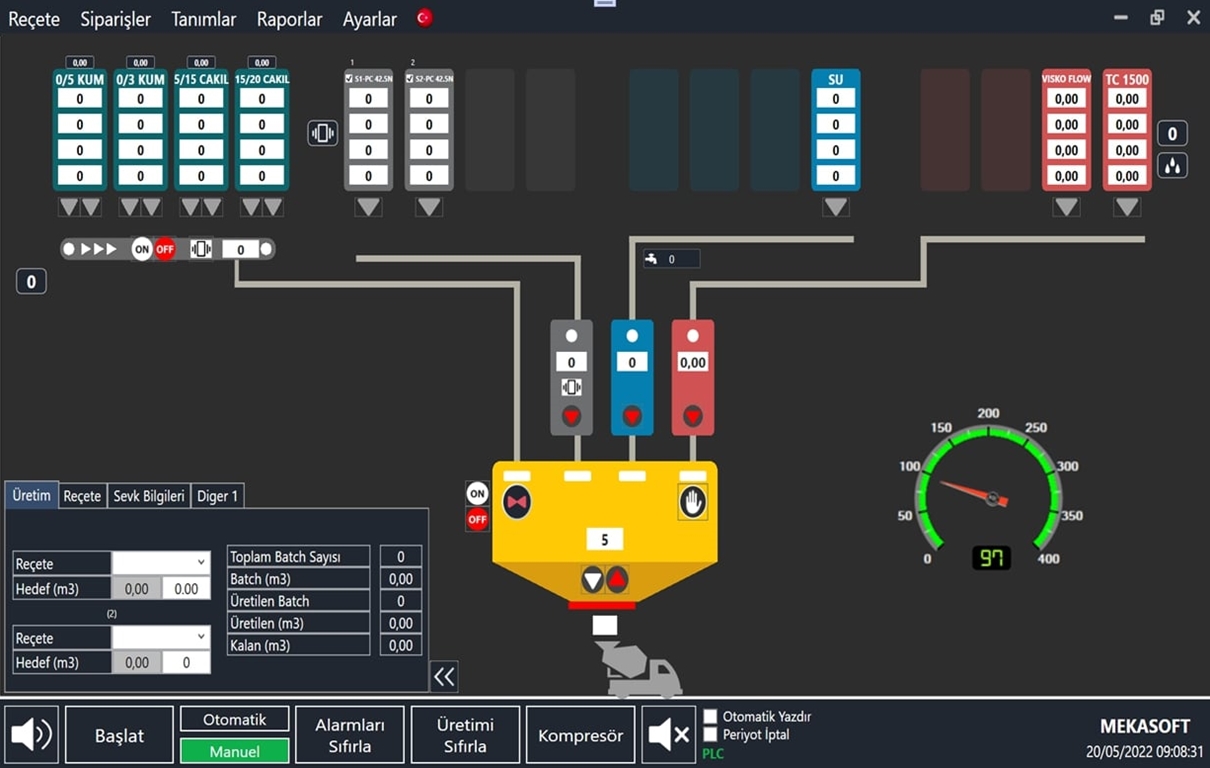

MEKASoft Concrete Plant Automation works with advanced control systems that optimize the concrete production process. It ensures that raw materials are mixed in the correct proportions, the production process is automatically managed, and continuous data tracking is provided.

MEKASoft is compatible with different production facilities and automation systems. It can be integrated with PLC and SCADA systems.

System management can be done via mobile devices or computers through a secure internet connection.

Pricing is determined based on capacity, technical requirements, and additional features. For detailed information, you can contact the authorized MEKA team.

Yes, MEKASoft provides comprehensive training and technical support services to its users. After system installation, detailed training is provided to ensure that operators and technical staff can effectively use the software.