Applications

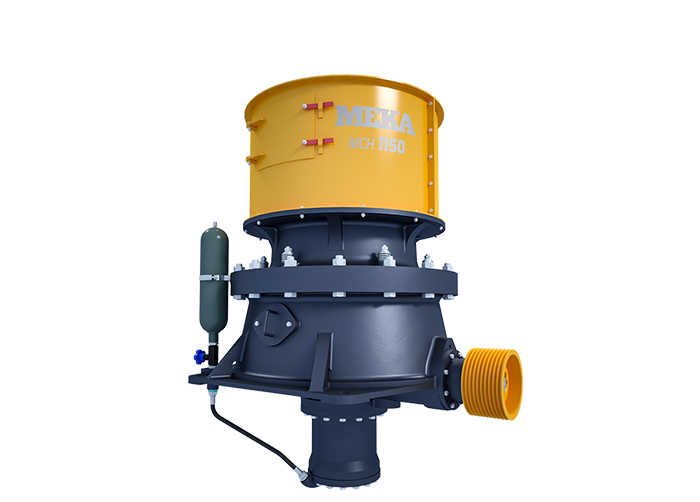

Why MEKA Cone Crusher?

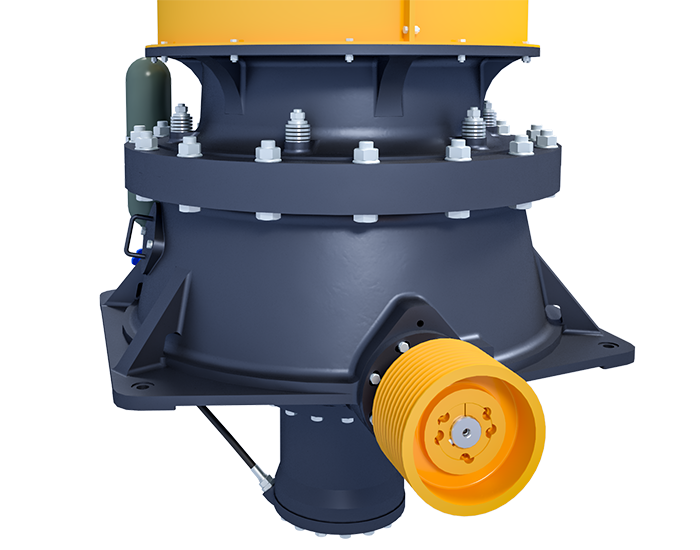

Rugged design provides the strength and stability necessary for the crushing of extra-hard materials.

The design also results in low maintenance costs,

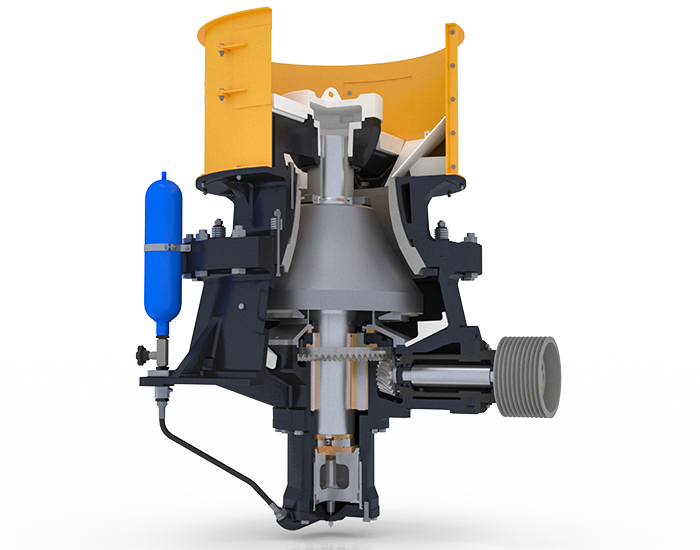

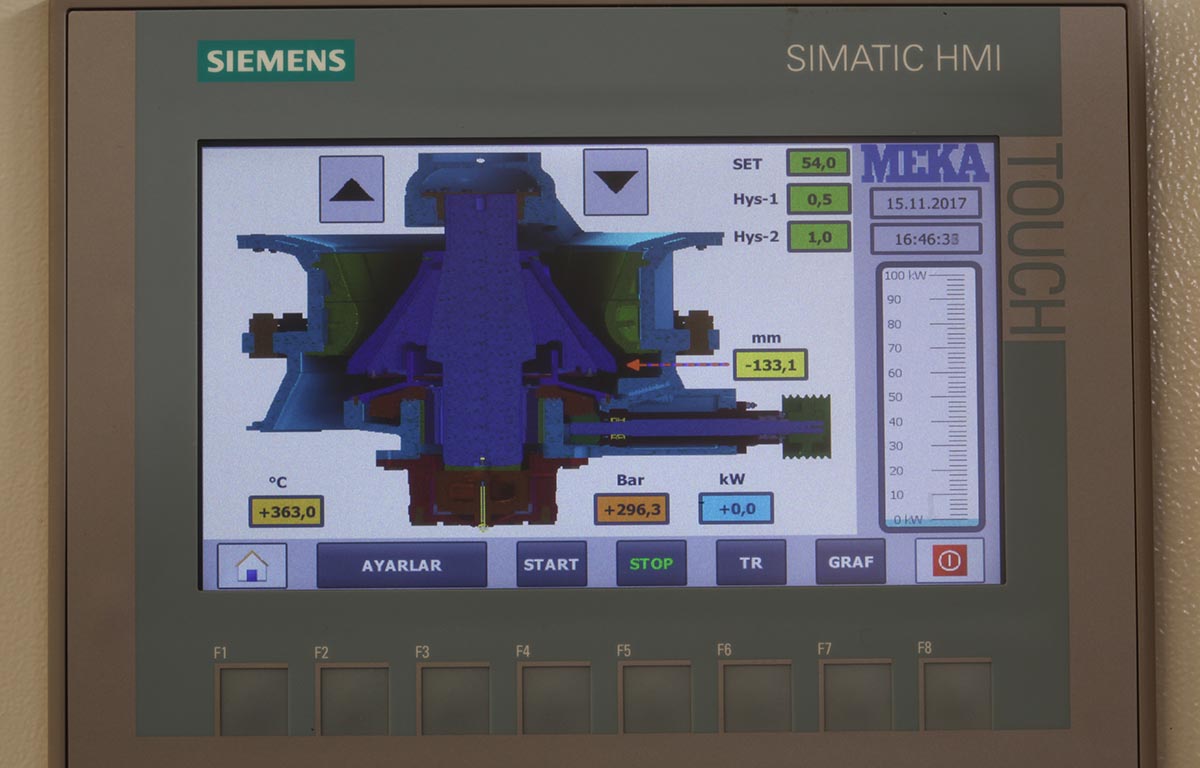

Hydraulic adjustment of the Closed Side Setting,

An easy-to-maintain Crusher,

An automatic overload protection system is standard,

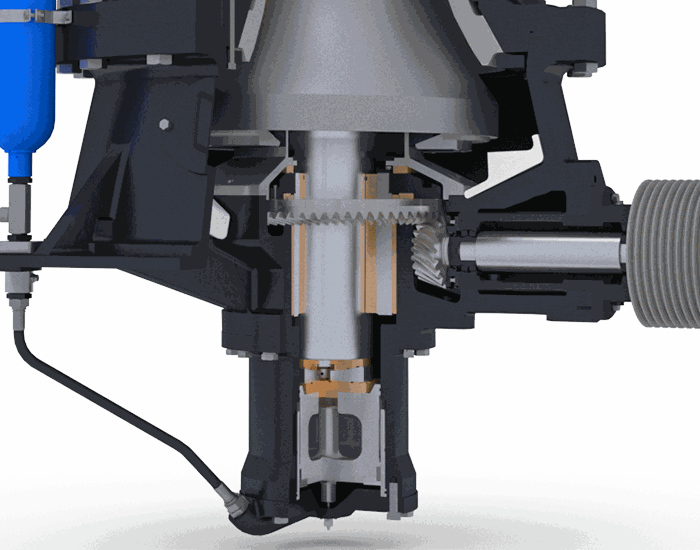

Product curve and capacity can be optimized by adjusting the eccentric bushing supplied with the crusher,

Quiet operation and long life thanks to bevel gears with hardened, spiralcut teeth.

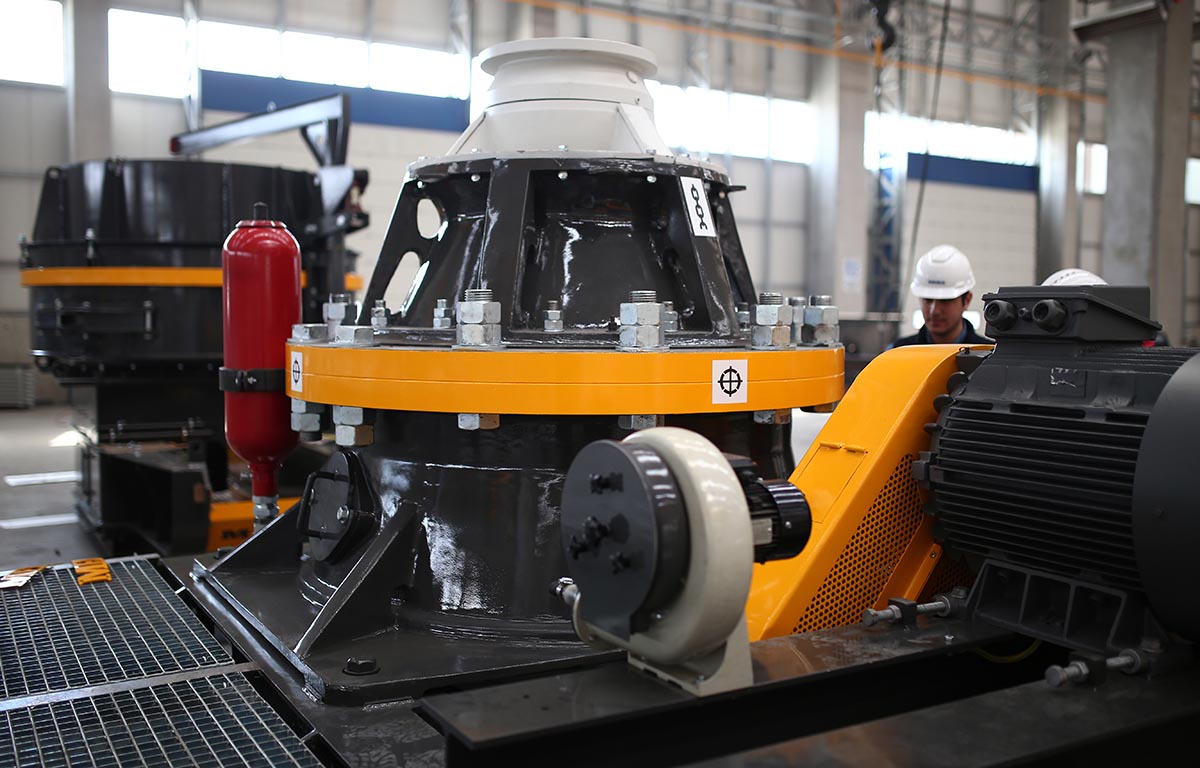

Cone Crusher Gallery

Cone Crusher Technical Specifications

MCS300 |

MCH300 |

MCH400 |

|

| *Capacity (mtph) | 110-230 | 50-190 | 90-340 |

| Motor Power (kW) | 132 | 132 | 250 |

| Max. Feed Size (mm) | 190-270 | 50-180 | 70-210 |

| Concaves | EC, C, MC | EC, C, MC, MF, F | EC, C, MC, MF, F |

| CSS (Min - Max Setting) (mm) | 25-48 | 16-36 | 13-44 |

| Eccentric Throw Range (mm) | 16-30 | 16-34 | 16-40 |

| **Weight (kg) | 14100 | 11600 | 18200 |

*For material weighing 1.6 t/m³ or 100 lbs/ft³. Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture content, crushability of the material, crusher rpm, installed power and the crushing circuit design.

** Weights shown do not include drive motor package, support legs, maintenance platform, inlet and outlet chutes.

What is Cone Crusher?

Cone crushers comprise two main parts: a fixed conical body that narrows toward the top, and a movable cone at the top that is mounted on an eccentric shaft through the center of the body. Under the effects of the eccentric shaft, the inner cone rotates within the fixed outer cone causing the distance between the inner and outer lining to narrow and expand, and any rock fed between the two linings is broken. In these crushers, the crushing process relies on compressive force, and the ore fragments break into smaller sizes as they move towards the bottom of the crusher and the outlet mouth under their own weight.

*The possibility to use in the secondary, tertiary and quaternary stages in a wide range of applications.

*Cone crushers have less operating cost in hard and abrasive material crushing.

*Cone crushers are robust construction and reliably withstand the heavy-duty crushing applications