Ore Characteristics

Each ore has specific grindability index. While some ores can be easily, others require higher energy for grinding. The physical structure of the product obtained after may change. The ore can be into powder or large chunks. Each ore abrades theiners to some extent during

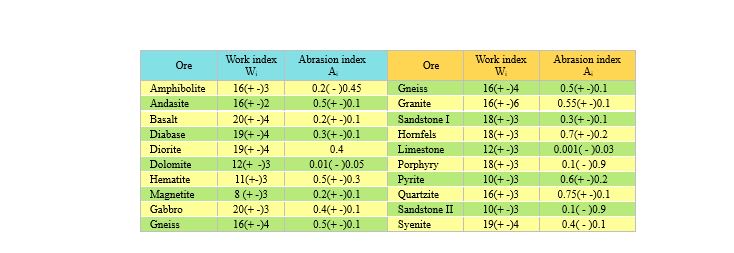

Size reduction tests carried out in a laboratory are essential to select the right for duty. There are three important values for grindability: rock’s chemical analysis, abrasion index (Ai) and work index (Wi). These can be easily obtained through laboratory tests.

The characteristics of the ore to be should be taken into account when selecting the right model. The grindability characteristics of the same ore may vary within certain ranges. To make a good selection, the size of the ore, the size to which it will be reduced, and feed capacity must be known. When choosing a type, the stages and the potential factors that may arise at each stage should be taken into consideration.

Work index (Wi) of ores is the primary measure of grindability. Ores with a low work index are easy to and require a low amount of energy for size reduction. Ores with a high work index require more powerful with bigger motors.

Impact are not suited to ores with a high abrasion index, such as quartzite. Quickly wearing parts increase operational costs and downtime during wear parts changes.

Aggregates for construction need to be free of internal stresses. Even though jaw are used as primary impact should be employed as secondary to reduce internal stress in the final product.

Double-toggleare known to have a high effectiveness inores with an Ai value above 0.7. Gyratory and cone operate like and are known as low-abrasion ith an abrasion index above 0.15, as they result in excessive abrasion.