Simply fill out the form to review our comprehensive catalog of product solutions for crushing, screening, and mining equipment.

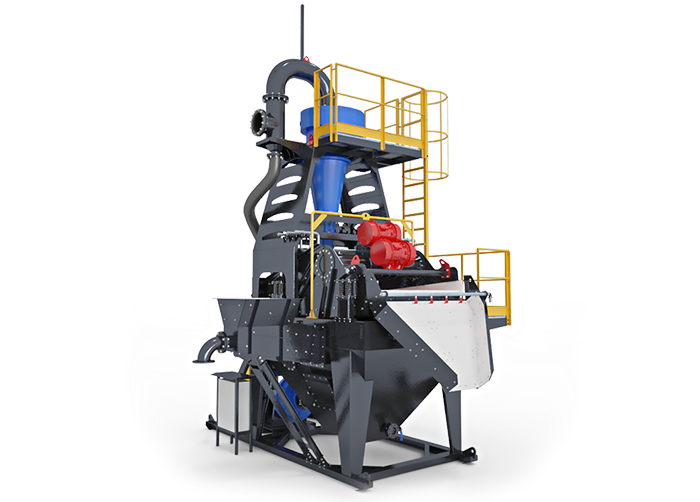

Compact Sand Plants Gallery

Maximum efficiency in sand production

Using clean sand in ready-mix concrete production and other industrial processes helps reduce the use of certain components (cement, additives, etc.). MEKA Compact Sand Washing Plants are designed to efficiently remove silt, clay, salt, various minerals, and other contaminants from sand. The unit includes a mud tank, slurry pump, hydrocyclones, and a polyurethane dewatering screen. This combination processes fine material discharged from the washing screen and ensures clean and high-quality sand suitable for concrete and asphalt applications.

MCSP Series Compact Sand Plants, featuring a screw washer tank, chassis-mounted dewatering screen, and recovery cyclones, reduce water consumption and maximize overall efficiency by recovering valuable fine sand.

Whether converting crusher dust into saleable sand or recovering fine particles from recycling and sludge processes, MEKA plants stand out with their robust structure, high-quality components, and easy-to-replace wear parts. They offer low maintenance costs and a long service life.

Applications

High-quality sand supply for concrete and asphalt production

Natural or crushed sand washing processes

River, sea sand, and excavation sludge treatment

Processing of fines from the washing screen

Cleaning aggregates with high clay/silt content

Recycling applications

Plaster sand, frac sand, foundry sand, glass sand, etc.

Compact Sand Plant - MEKA Washing Plants

Compact Sand Plants Technical Specifications

MCSP 90 |

MCSP 150 |

MCSP 210 |

|

| *Capacity (mtph) | 90 | 150 | 210 |

| Maximum Water Requirement (m³/h) | 270 | 450 | 630 |

| Cyclone Diameter (mm) | 500 | 660 | 2 x 660 |

| Screen Motor Power (kW) | 2 x 2,88 / 1500 rpm | 2 x 7,35 / 1500 rpm | 2 x 6,1 / 1000 rpm |

| Dewatering Screen Size (mm) | 1200 x 2400 | 1800 x 2400 | 1800 x 4000 |

| Pump Size (inch) | 8"/6" | 10"/8" | 10"/8" |

| Pump Power (kW) | 45 | 55 | 75 |

| **Weight (kg) | 7475 | 10900 | 16750 |

*Capacity values are indicative only, results may vary depending on feed gradation, silt, clay content,density, amount of water used, equipment configuration and application.

**Weights shown include drive motor package, support legs, maintenance platform, inlet and outlet chutes

Would you like to request a quote or receive information about a compact sand plants?

Would you like to receive a price quote for a MEKA compact sand plants?

Do you need a compact sand plants with different options and configurations?

Do you want to become a MEKA compact sand plants dealer?

Let's move on to the next level. Contact us now by filling out the form.

What is Compact Sand Plants?

The compact sand plant is a unit which comprise of cyclone, pump and dewatering screen on one chassis used to improve sand quality.

*Increases fine recovery in the sand washing and treatment process.

*These units are engineered to deliver high-quality sand.

*Can produce two different sizes and grades of sand as needed.