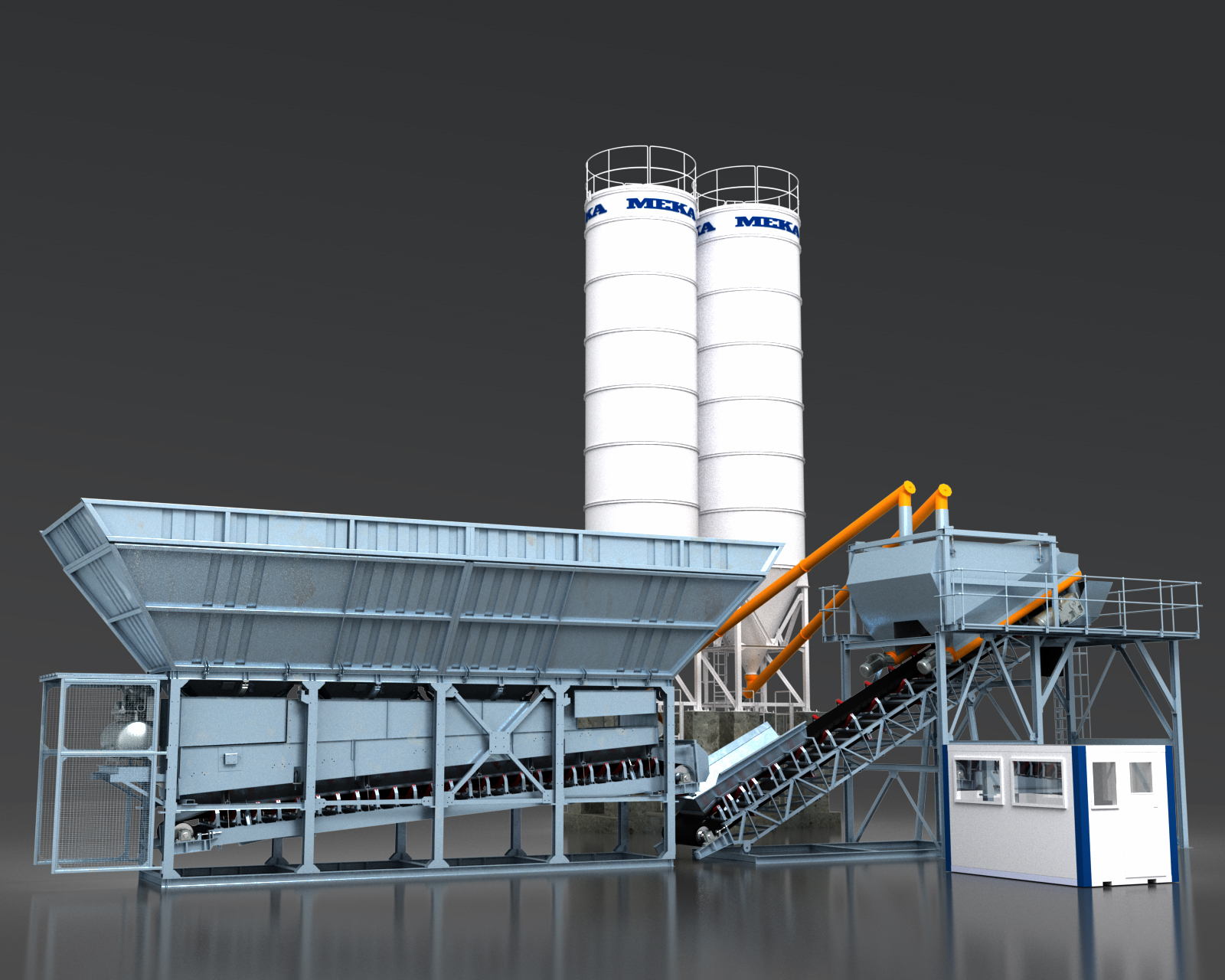

What is Dry Batch Concrete Batching Plant

Choosing A Suitable Concrete Batching Plant According to The Construction Characteristics

Ready-mixed concrete is a concrete that produced according to the procedures determined in the batching facilities and delivered to the building site by the mixer truck.

Types of Concrete with Different Production Procedure

There are mainly two types of and they have four combinations which works with different production procedure.

- Dry batch concrete plant

- Wet batch concrete plant

- Half-wet batch concrete plant

- Combination batch concrete plant

It is important to choose a suitable concrete batching plant according to the construction characteristics to be built and the transportation facilities. From the point of view, the difference between dry mixed concrete plant and wet mixed concrete plant is not only the wet mixture or dry mixture but also have other important differences. Dry concrete batch plant is a special plant used to mix concrete with compared to the other batching plants. The dry mixed concrete plant has higher efficiency, but it must work with the mixer truck to mix the concrete.

Also known as dry mix have sand, gravel, and cement feeding to batching plant that pass the numerical or manual scale. Then all the raw materials are discharged into a chute into the truck. At the same time, the water is weighed, or volume metered and discharged into the mixer truck through the same charging tank. At last, all the material mixed and transported to the site.

Wet uses a cwith mixing all of the above-mentioned components (including water) in a central location, the is stirring on the way to the site to prevent the setting (using agitors or pre-mixed cars).

Like a mobile and a stationary , the dry consists of cement silos, feeding system, control system, weighing system and mixing system. Cement silos are the catching and supply of raw materials such as cement, sand and fly ash as production necessitates. The feed system is a bridge to connect the aggregates and the mixing system. The accuracy of the weighing system determines the amount of mixed materials, and therefore has a great influence on the quality of the mixed The mixing system only mixes the materials without water. As a result, the mixer truck is important for transporting and mixing . The control system is the core of the whole plant. Workers can reach full automation by using cin the control room.

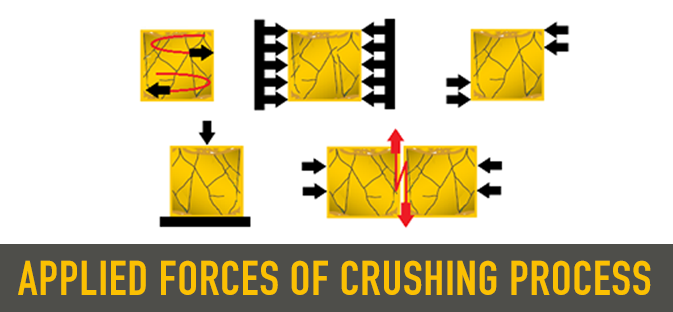

Dry mixing differs from wet mixing equipment. A wet mix containing a central while dry mix can provide a more consistent mixture in a shorter period of time. Dry batching plant will usually see more variations in standard deviation of breaking strength and changes from load to load, because while mixing cement, stone and other mixture can be mixed systematic than the wet type mixing. Some combine dry and wet mix characteristics to increase the application.

Advantages of Dry Concrete Batching Plants

- It has higher capacity and lower energy consumption becausecan be mixed without water

- The cooperation between the dry batching plant and the mixer truck can increase productivity and save time.

- The fresh can be used because of the mixer trucks arrive at the construction site.

- It shortens the construction and enhances productivity.

- It’s got lower power consumption when compared to the wet mix plant.

- Operating costs of dry-batch are relatively low

- Allowso be mixed more efficiently.

- It could be the short time period of maintenance needed when compared with wet mix plants.

- As in other mixing plants, such as mobile and stationary the dryplant is also automated.

- If the site is quite long, it is an ideal choice for dry manufacturers. While the mixer truck going to the construction site, it may keep the rotation order to prevent tampering, hardening of the mixed and to ensure the freshness of the materials.

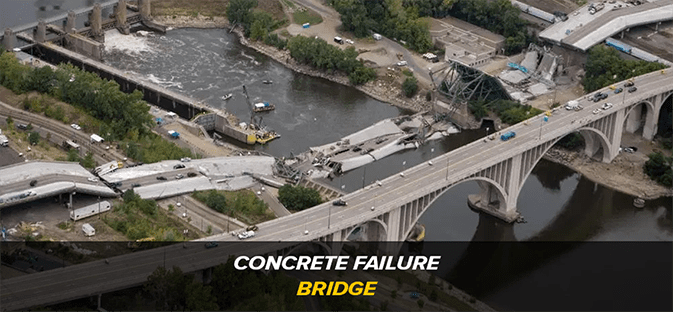

- Dry batch vegetation is much-welcomed modernproduction equipment that is constantly significantly assist in the development and development of modern roads, bridges and various construction works.