Aggregate Washing Equipment

To produce standardised, clean, and washed aggregates and sand

We offer an extensive product portfolio for various applications, supporting customers in wet processing applications. MEKA products have excellent reliability, are easy to transport, operate, and provide fast onsite installation.

MEKA Wet processing equipment offers profitable solutions with its unparalleled durability and efficiency in aggregate and sand manufacturing, mining, and construction, demolition & excavation waste recycling applications.

-

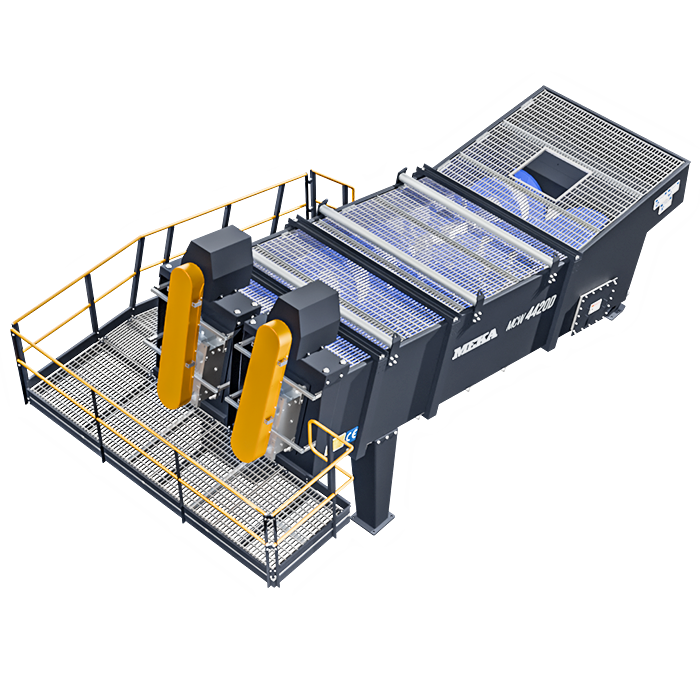

Maximum Material Size: 102 mm (4 inch). Its function is to remove mined and quarried materials from hard and sticky clay and dirt by scrubbing them together.

-

Maximum Material Size: 75 mm (3 inch). Its function is to remove the clay, mud, dirt and other foreign materials in the aggregate (usually in the aggregate between 10-80 mm, called coarse aggregate) that cannot be cleaned by wet screening in the most efficient way.

-

Maximum Material Size: 10 mm (3/8 inch) Its function is to purify fine aggregate and sand from silt, mud, dirt and other foreign matter, thus providing a clean and high-quality final product. Learn about the details of MEKA Fine Material Washers.

-

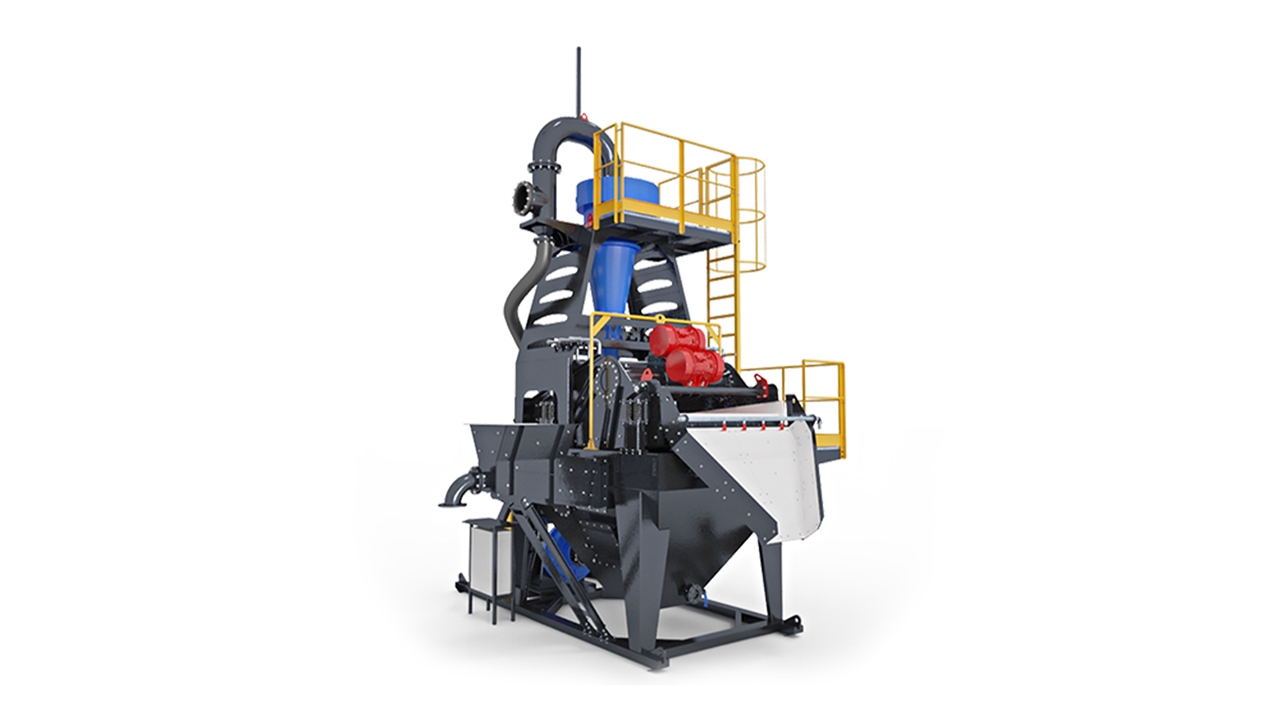

Type of Material Processed: Natural or industrially produced sand. Its other name is Cyclone Sandwashers, and its mission is to provide a comprehensive solution, producing clean sand through sand washing, dewatering, and the recovery of fine materials.

From Experience to Perfection

Since 1987, MEKA Global has been involved in the design, manufacture, and installation of static and portable aggregate processing plants and concrete batching plants throughout more than 110 countries.

Contact us and turn materials into revenue!

How much does a log washer cost?

Can I get a price quote?

Can I become a dealer for your equipment?

Can I learn about your washing equipment references in the US?

How long does it take to deliver fine material washers?

And all your questions...

Let's move on to the next level. Contact us now by filling out the form.

Can I get a price quote?

Can I become a dealer for your equipment?

Can I learn about your washing equipment references in the US?

How long does it take to deliver fine material washers?

And all your questions...

Let's move on to the next level. Contact us now by filling out the form.