DISCOVER MORE

Briefly C60 S

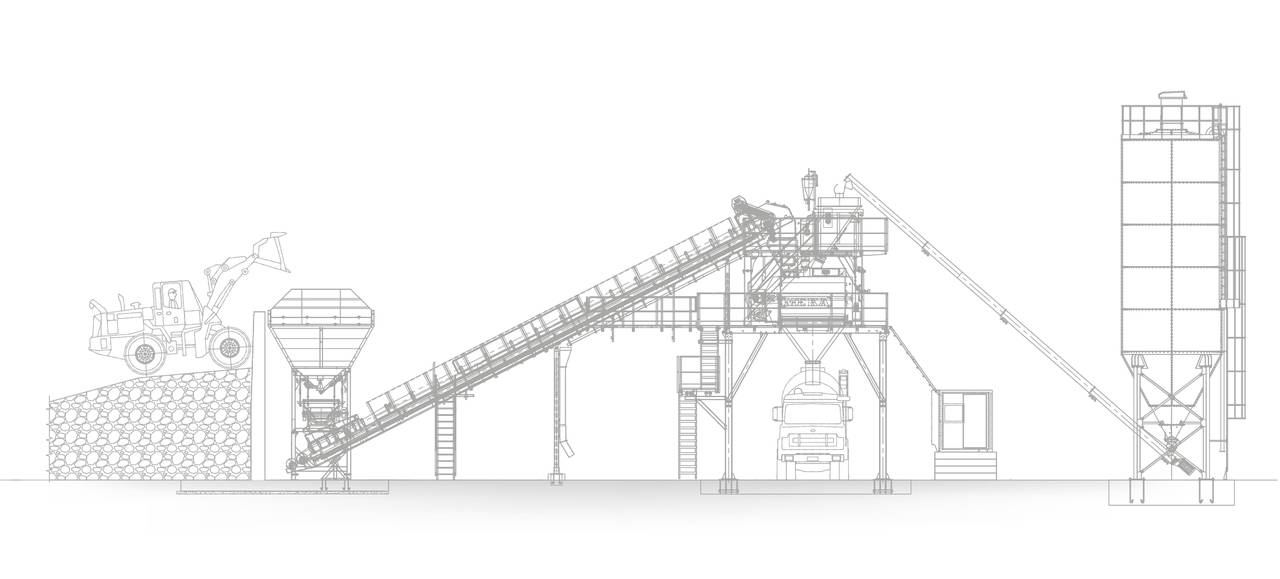

The C60 S Compact Concrete Batching Plant is designed to require minimal installation space, thanks to its bucket structure, and can be shipped using 40' open-top containers. Engineered for maximum efficiency and built with top-quality components, the C60 S is the ideal solution for medium-sized concrete production, particularly in tight spaces.

Equipped with a 1.0 m³ capacity MEKA twin-shaft mixer, the C60 S ensures uninterrupted production while keeping operating and maintenance costs low. It offers flexibility with two aggregate bunker options: 4x10 square type or 4x20 in-line type.

The C60 S can be installed directly at ground level without the need for special high concrete foundations. Pre-wired electricity, water, and pneumatic lines prepared at MEKA’s factories enable rapid installation and commissioning, allowing the plant to start producing concrete in no time.

C60 S Compact Concrete Batching Plant Components

C60 S Compact Batching Plants Gallery

Optional Features For All MEKA Concrete Batching Plants

Your concrete batching plant investment purpose and your expectations from the plant may vary different.

Whether you are a ready-mixed concrete producer, a contractor or a manufacturer of precast building elements, we have a very strong R&D team and international experience since 1987 to design and manufacture the most suitable batching plant for your needs.

Here are some of our customization options. Our technical sales team can support you in assiting the appropriate layout and equipment to optimize your productivity and business.

DISCOVER MORE

DISCOVER MORE