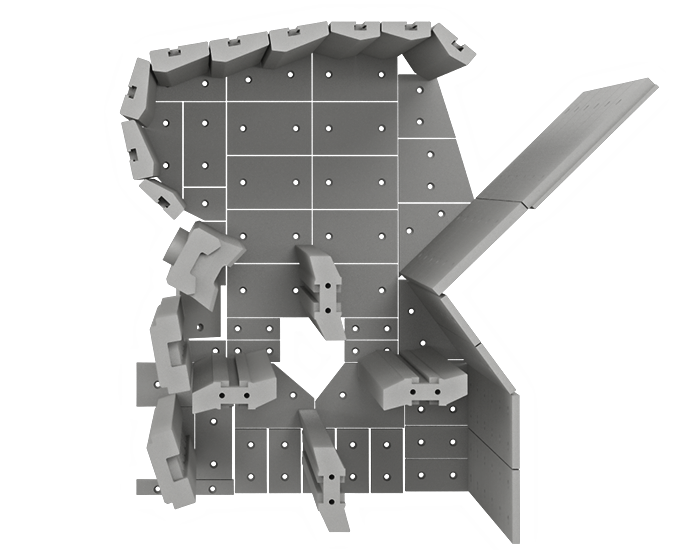

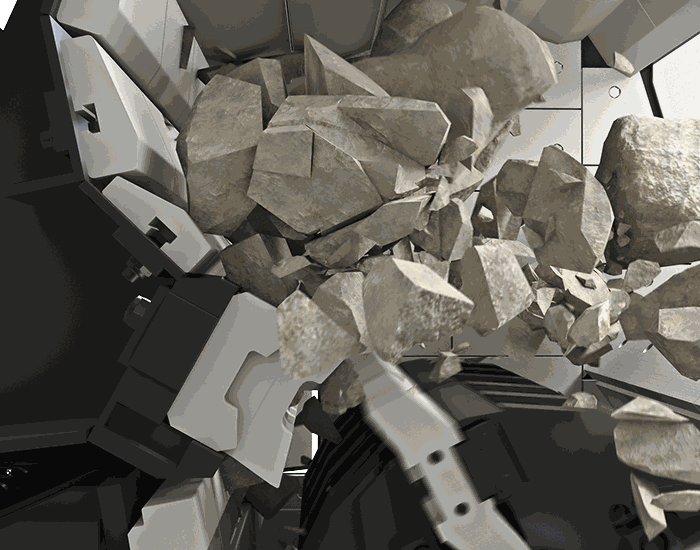

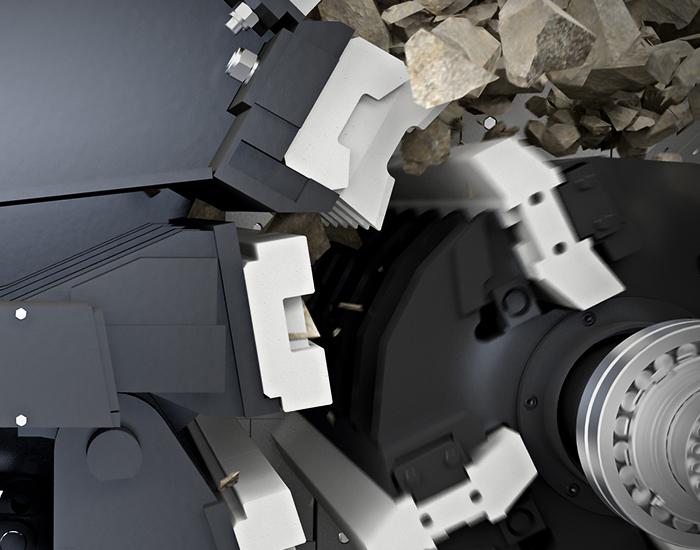

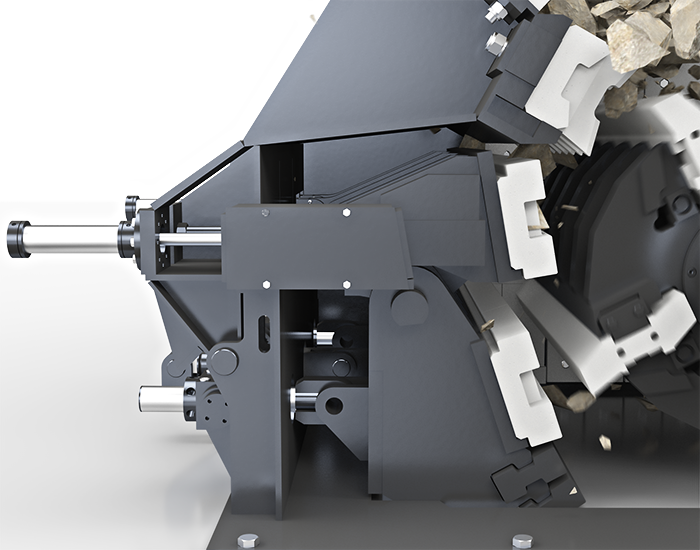

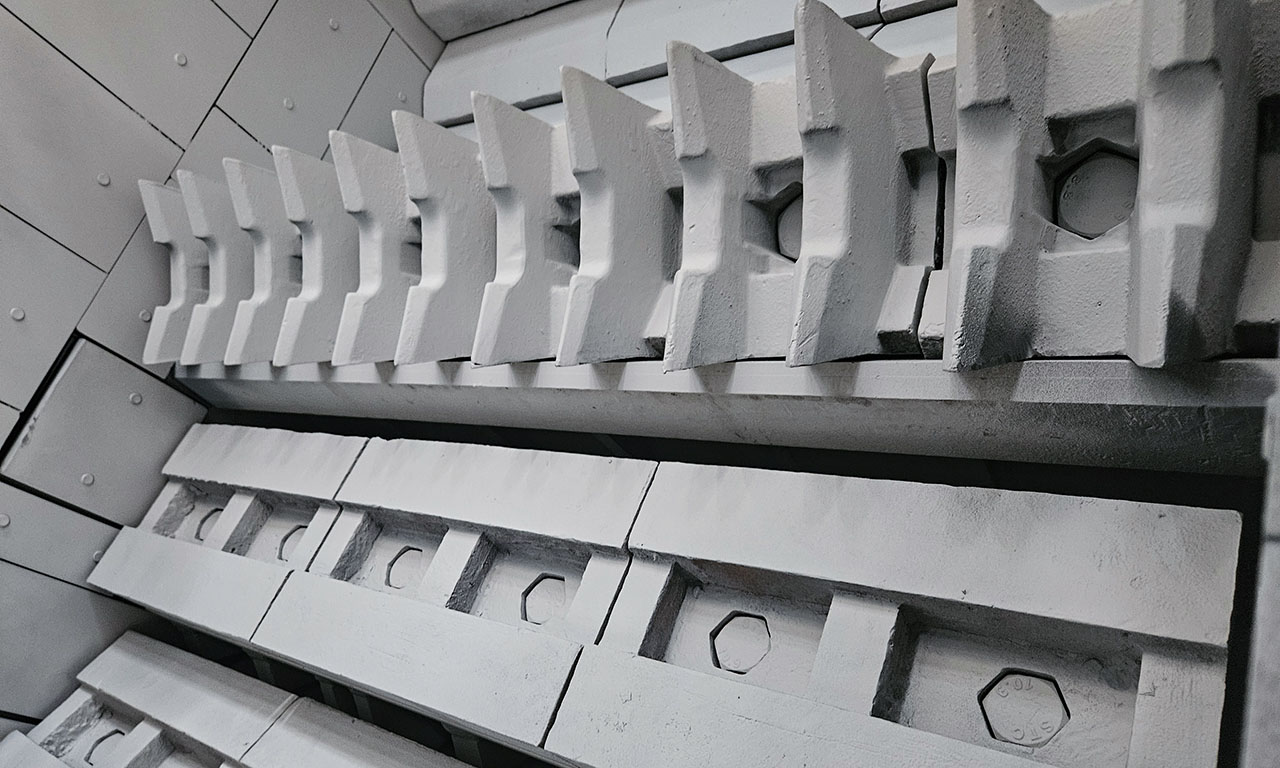

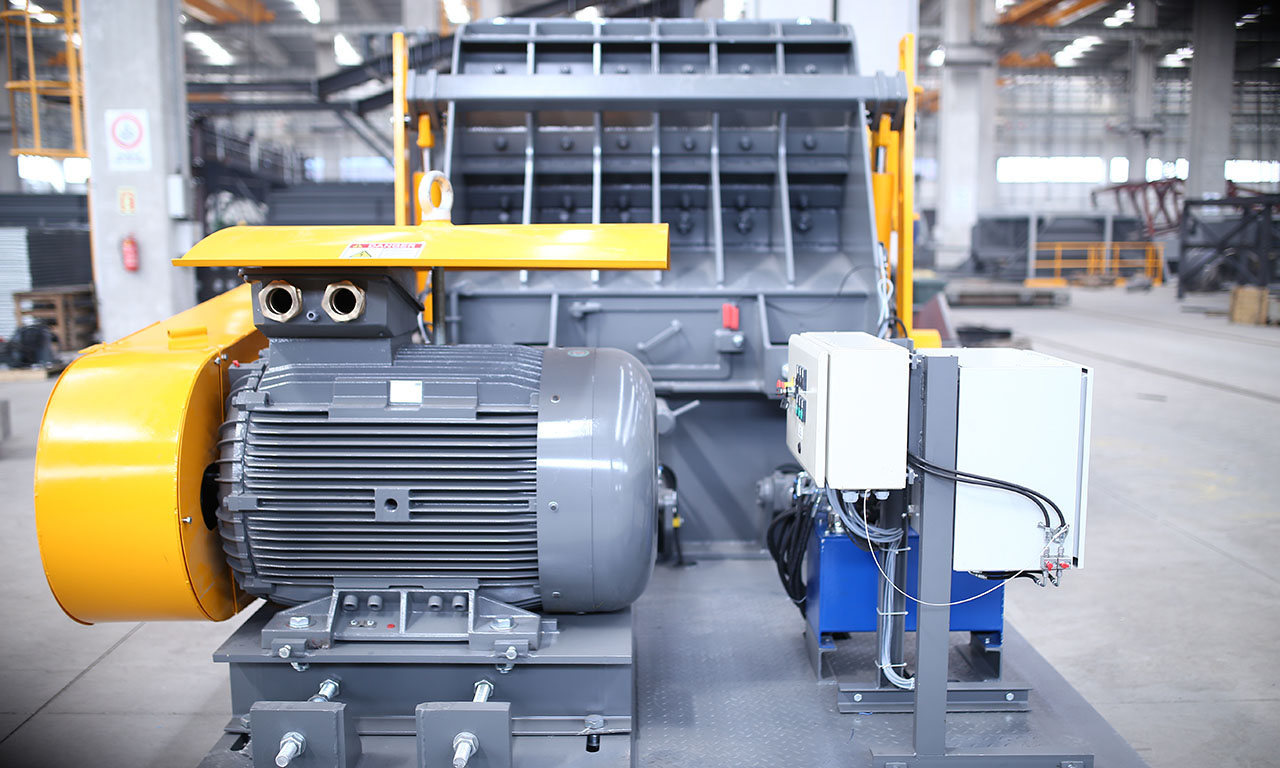

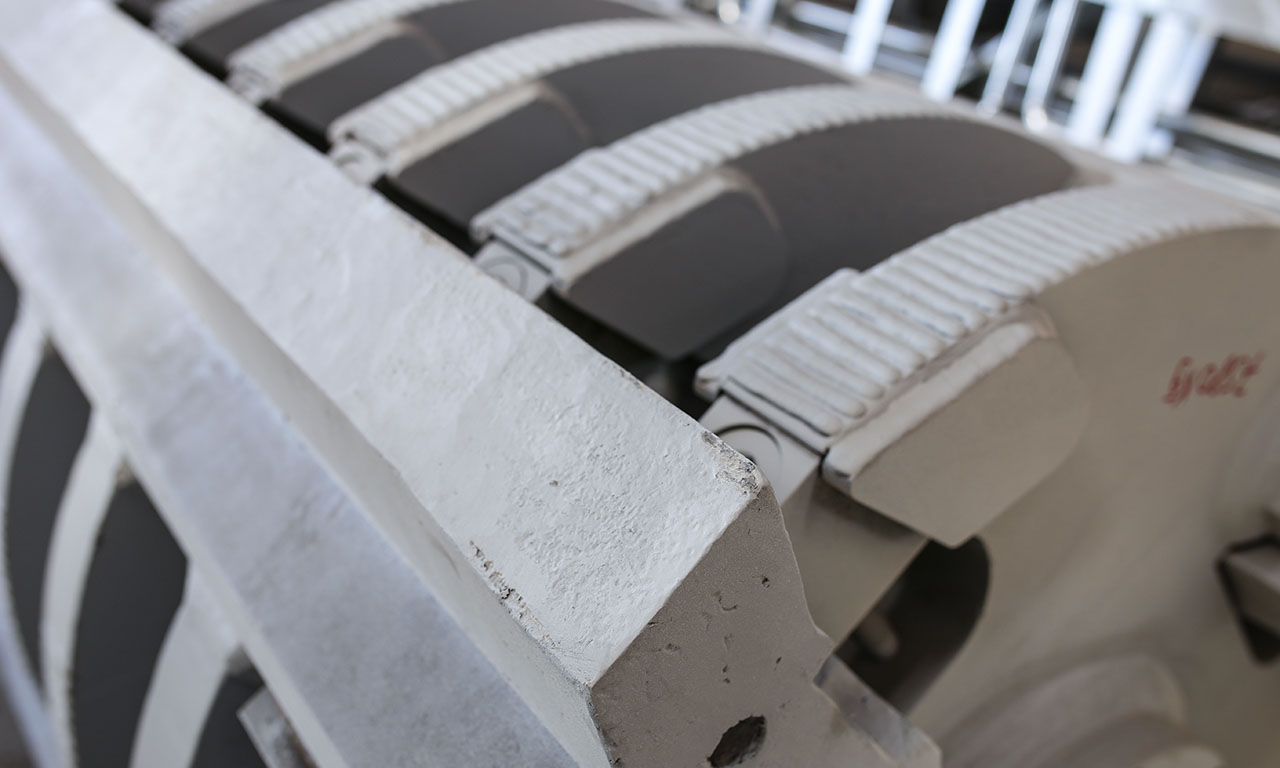

Different designs for soft and non abrasive feed material or for medium hard and slightly abrasive material are available. For hard and abrasive material, crushers have special heavy-duty design of the body, rotor and the breaker bars and blowbars are with higher chromium content castings. These crushers are also equipped with a third breaker plate producing higher amount of fines.

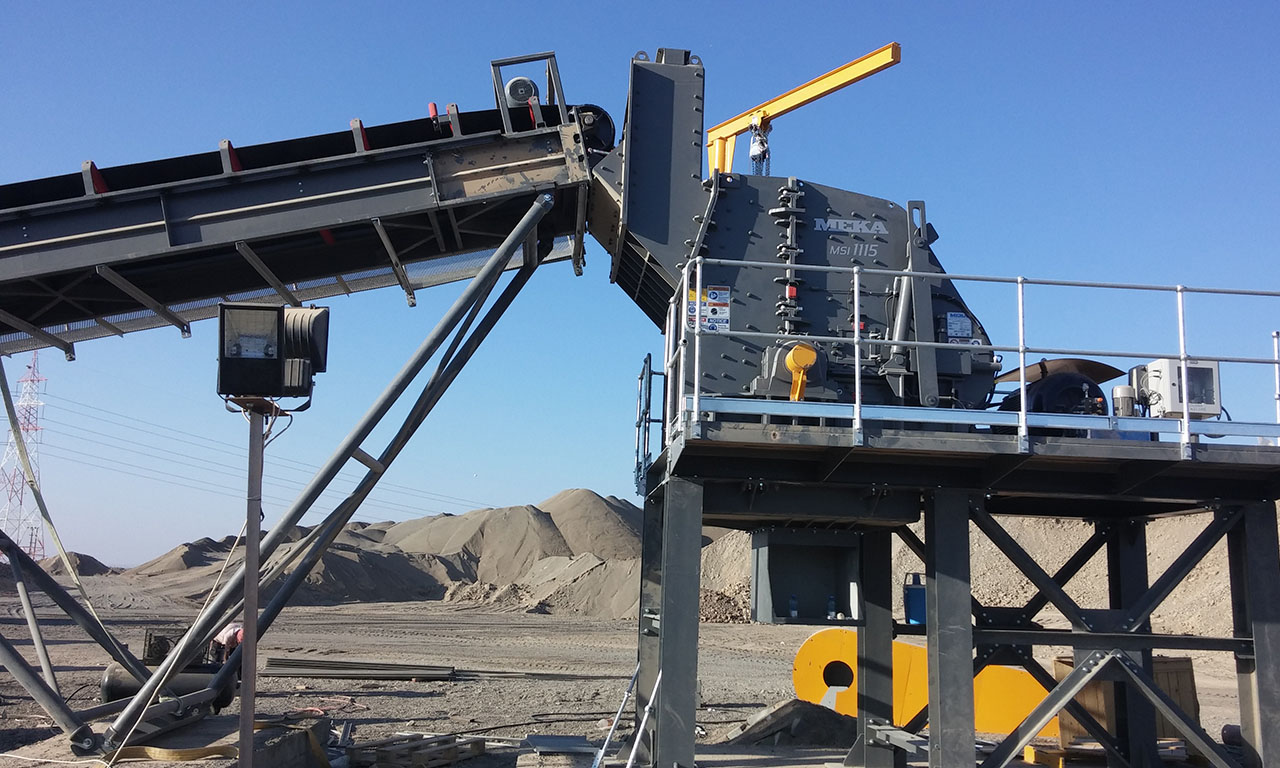

MEKA MSI Series Secondary Impact Crusher is ideally suited to crush soft to medium hard materials of medium to low silica content such as limestone, gypsum. MEKA MSIH Series Secondary Impact Crusher is the economical alternative to cone crushers for hard stone. They are suitable for several raw mineral materials with varying degrees of hardness, from soft to brittle materials to hard rocks and iron free recycling material.