What is Secondary Crusher?

What is Secondary Crusher?

In the quarry, crushing is handled in four potential stages: primary, secondary, tertiary and quaternary. The reduction of aggregate is spread over these stages to better control the product size and quality, while minimizing waste.

Secondary crushing accepts the material from the primary crushing stage and aims to further reduce the size of the material produced in the first stage. The primary goal is to achieve a specific particle size distribution suitable for downstream processing, such as screening or tertiary crushing.

Characteristics of Secondary Crushing:

Material Size: Secondary crushing typically reduces material sizes to between 25 to 100 mm (1 to 4 inches).

Throughput: Secondary crushers generally have a higher throughput than primary crushers, allowing for increased efficiency in the crushing process.

Product Shape: The product shape from secondary crushing is often more uniform and consistent, improving the quality of the final product.

Types Of Crushers To Use During The Secondary Crushing Stage

The equipment commonly used for secondary crushing includes: Horizontal Shaft Impact (HSI) Crushers and Cone Crushers. Occasionally,Vertical Shaft Impact (VSI) Crushers and Hammer crushers may be applied as a secondary crusher.

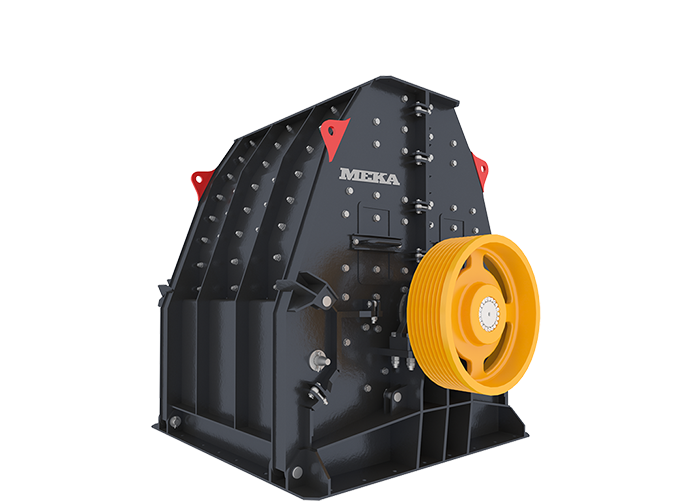

Horizontal Shaft Impact Crushers (HSI)

As the name implies, the horizontal-shaft impact (HSI) crusher has a shaft that runs horizontally through the crushing chamber, with a rotor that turns blow bars. It uses the high-speed impacting force of the turning blow bars hitting and throwing the stone to break the rock. It also uses the secondary force of the stone hitting the breaker plate liners in the chamber, as well as stone hitting stone.

With impact crushing, the stone breaks along its natural cleavage lines, resulting in a more cubical product, which is desirable for many of today’s specifications.

Gradation changes are made by either changing speed of the rotating rotor and the gap setting between the adjustable breaker plates and the rotor. Faster speed results in finer output, while adjusting the breaker plates also affects the overall reduction.

These impact-type crushers offer reduction ratios of 8:1 to 10:1. They are ideal for soft to medium hard, slightly abrasive materials.

Advantages:

- Capable of delivering a much more homogenous, consistent and cubical end product. This makes impact crushers favourable when the final result needs to be a saleable commodity,

- Use comparatively low energy compared with other crushers types,

- Versatile and can process a variety of different materials, including concrete, soft rock, hard rock, gravel and even asphalt,

- Have a fairly large feed inlet and sizeable crushing chamber and, if used with less abrasive materials, can lead to an economical and reliable crushing operation,

Have a high reduction ratio.

Disadvantages:

- Require more maintenance than compression style crushers – especially if crushing hard and abrasive materials. This is because the material in an impact crusher is constantly colliding within the crusher at high velocities to break the rock apart. This contributes to much wear and tear, although modern wear-resistant materials have made impact crushers more popular,

- When crushing very soft materials, excess fines can be produced. This contributes to more potential dust pollution as well, which can be an occupational health and safety concern if not mitigated through the implementation of dust control measures.

MEKA MSI Series Secondary Impact Crusher

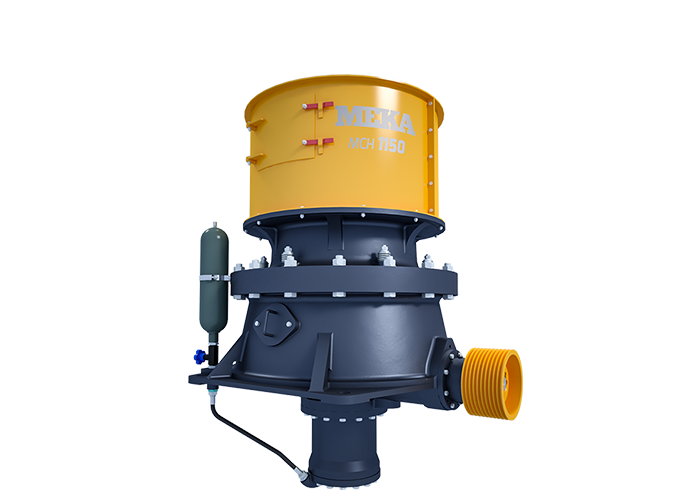

Cone Crushers

Cone crushers are compression-type crushers, which reduce material as it advances downward through the chamber (with the help of gravity and the weight above) by means of squeezing the material between a moving piece of steel (mantle) and a stationary piece (concave). Eccentric rotation causes the main-shaft and the head to wobble.

Rock is fed into the open top and gravity pulls it through the tapered crushing chamber. As the chamber gets tighter, the material gets smaller until it is small enough to pass through the cavity at the bottom of the crusher.

The gradation is controlled by adjusting the distance between the stationary concave and the moving mantle at their closest points. However, adjusting the closed-side setting tighter reduces the throughput capacity of the machine.

Cone Crushers are are well suited for hard to medium hard materials. They perform well in abrasive material with relatively low operating costs. In secondary applications, they typically provide a reduction ratio of 6:1.

With proper choke-feed, cone-speed and reduction-ratio settings, cone crushers will efficiently produce material that is high quality and cubical in nature.

MEKA MCH Series Cone Crusher

Hammer Crushers

Although not frequently used, hammer crushers can be installed at the secondary stage where the incoming feed material is reduced to an acceptable size in a primary impact crusher with grinding path.

Hammer crushers are similar to secondary impact crushers in the upper chamber where the hammer impacts the in-feed of material. The difference is that the rotor of a hammer crusher carries a number of “swing type” or pivoting hammers. Hammer crushers also incorporate a grate circle in the lower chamber of the crusher. Grates are available in a variety of configurations. The product must pass through the grate circle as it exits the machine, insuring controlled product sizing.

These crushers offer reduction ratios as high as 20:1. They are adept at handling less abrasive materials in aggregate and industrial applications.

MEKA MHC Series Hammer Crusher

Vertical Shaft Impact Crushers

In some well defined applications, vertical shaft impact crushers with shoe and anvil configuration(SOS) can be used at the secondary crushing stage.

The vertical shaft impact crusher (or VSI) has a rotating shaft that runs vertically through the crushing chamber. In a standard configuration, the VSI’s shaft is outfitted with wear-resistant shoes that catch and throw the feed stone against anvils that line the outside of the crushing chamber. The force of the impact, from the stone striking the shoes and anvils, fractures it along its natural fault lines.

These types of crushers are usually applied as secondary crushers with less than 75 mm (2”) feed or smaller.

Vertical Shaft Impact crushers are very application-specific. They are sensitive to abrasive materials and can experience very high maintenance and operating costs.

MEKA MVI Series Vertical Shaft Impact Crusher

How to choose the right secondary crusher?

Rock crushers come in many varieties, and companies need to find the right one for their unique needs. Each type of crusher has its own strengths and weaknesses, so it is important to carefully consider the materials to be crushed, as well as the size and shape of the rocks.

Three factors are of prime importance in selecting the size and type of the secondary crusher, or crushers:

Capacity;

Size of feed,

Size of product.

You add to these the item of product characteristic, which embraces shape characteristic, and gradation. These are not always important, but they are sometimes very much so.

Where can I buy a secondary crusher?

Would you like to buy a secondary crusher? Contact MEKA GLOBAL today. We have experts on hand to help you find the best equipment for your needs and budget. Want to upgrade your equipment for more efficient crushing? We can help you with that too with our full range of feeders, crushers, screens and more.