Simply fill out the form to review our comprehensive catalog of product solutions for crushing, screening, and mining equipment.

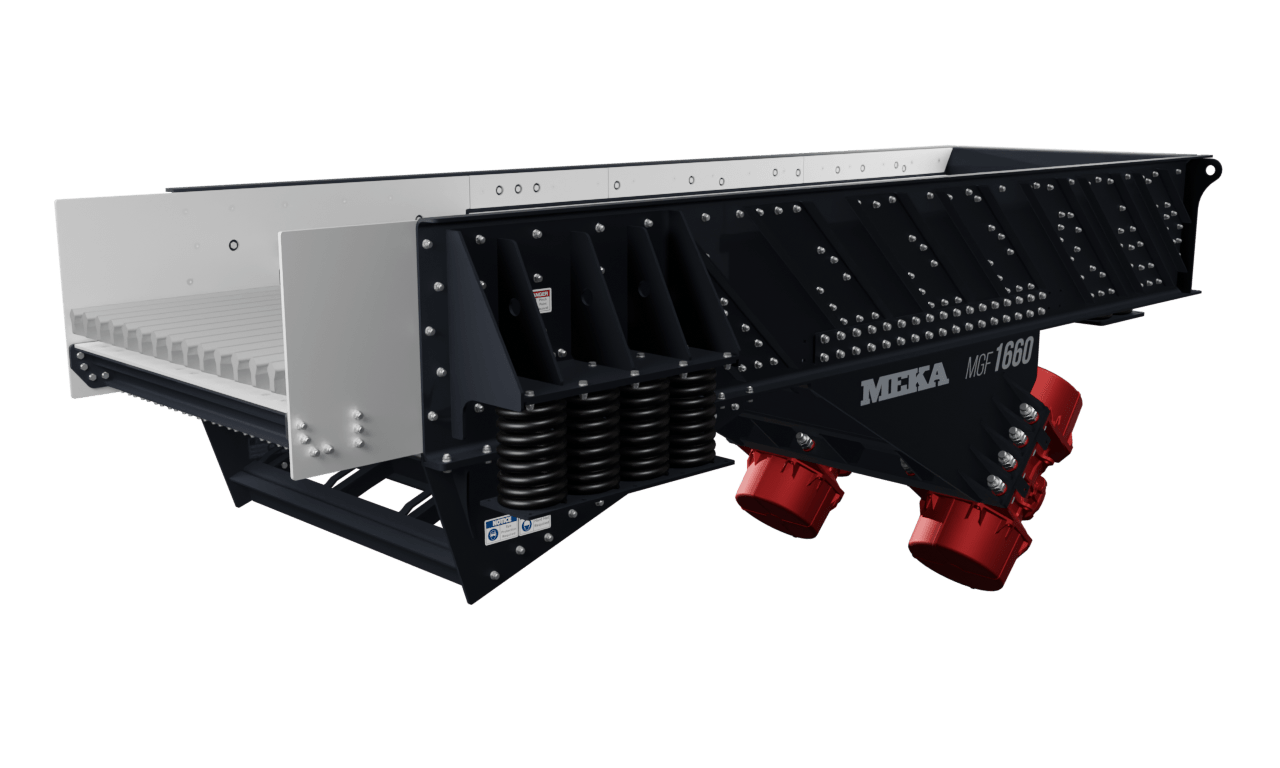

Grizzly Feeder Gallery

More efficient plants with extra durable MEKA Grizzly Feeders and consistent feeding

MEKA Grizzly Feeders increase your plant efficiency by ensuring uniform distribution and regular material flow across the feeder tray. During primary feeding, unwanted fines are separated to improve final product quality. The conical and deep-profile grizzly design of the MGF series prevents material build-up and clogging.

MEKA Grizzly Feeders, with heat-treated drive consoles and high-quality vibro motors or eccentric shaft drives, guarantee maximum efficiency, reliable feeding, and long-lasting performance with minimum downtime.

Applications

Used in mining, aggregate production, and recycling applications; ideal for feeding basalt, limestone, recycled materials, and river gravel.

Looking for a grizzly feeder that delivers superior performance under the toughest conditions and applications?

Grizzly Feeder Technical Specifications

MGF 0625 |

MGF 0942 |

MGF 1152 |

MGF 1260 |

MGF 1360 |

MGF 1460 |

MGF 1660 |

MGF 6530 |

MGF 1160 |

|

| Width x Length (mmxmm) | 620x2500 | 900x4200 | 1100x5200 | 1200x6000 | 1300x6000 | 1400x6000 | 1600x6000 | 650x3000 | 1066x6000 |

| *Capacity (mtph) | 100-200 | 250-400 | 400-640 | 450-750 | 500-825 | 550-875 | 650-1000 | 100-200 | 400-640 |

| Single Section | Single Section | Double Section | Double Section | Double Section | Double Section | Double Section | Single Section | Double Section | |

| Length of Grizzly (mm) | 1000 | 1500 | 2000 | 2800 | 2000 | 2800 | 2000 | 1000 | 1400 |

| Maximum Feed Size (mm) | 350 | 600 | 800 | 900 | 975 | 1050 | 1200 | 350 | 800 |

| Vibromotor | |||||||||

| Power @50hz (kW) | 2x3.8 | 2x6.1 | 2x10.1 | 2x11.9 | 2x13.9 | 2x13.9 | 2x13.9 | 2x3.2 | 2x10.1 |

| Speed (rpm) | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Power @60hz (kW) | 2x4.3 | 2x7.5 | 2x10.6 | 2x11 | 2x16.5 | 2x16.5 | 2x16.5 | 2x3.4 | 2x10.6 |

| Speed (rpm) | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

| Exciter Drive | |||||||||

| Power (kW) | - | - | 22 | 22 | 30 | 30 | 37 | - | 22 |

| Speed (rpm) | - | - | 500-800 | 500-800 | 500-800 | 500-800 | 500-800 | - | 500-800 |

*At specified inclination and for material weighing 1.6 t/m³ or 100 lbs/ft³. Capacity values are indicative only and depend not only on feeder size but also on feeder inclination, feed gradation, etc.

Would you like to request a quote or receive information about a grizzly feeder?

Would you like to receive a price quote for a MEKA grizzly feeder?

Do you need a grizzly feeder with different options and configurations?

Do you want to become a MEKA grizzly feeder dealer?

Let's move on to the next level. Contact us now by filling out the form.

What are Grizzly Feeder?

Grizzly feeders produce a linear motion in their pan and grizzly sections and are used in the primary feeding stage for the simultaneous performance of feeding and separation processes.

The grizzly opening of the feeder is selected according to the feed curve and closed side setting of the crusher to be fed . As a result, material smaller than the crusher setting is prevented from entering the crusher. The dirty material in the feed bypasses the crusher and is fed to a screen to be discarded as waste and the remaining clean material is fed to the post-crusher process.

Although it is possible to install grizzly feeders inclined, horizontal installation is widely preferred for separation efficiency. If an increase in capacity is needed, the installation angle can be increased by several degrees without loss of separation efficiency.