Different designs of crusher body, breaker bar arrangement, rotor shape, number of blowbars are available. For hard and abrasive material, crushers have special heavy-duty design of the body, rotor and the breaker bars and blowbars are with higher chromium content castings.

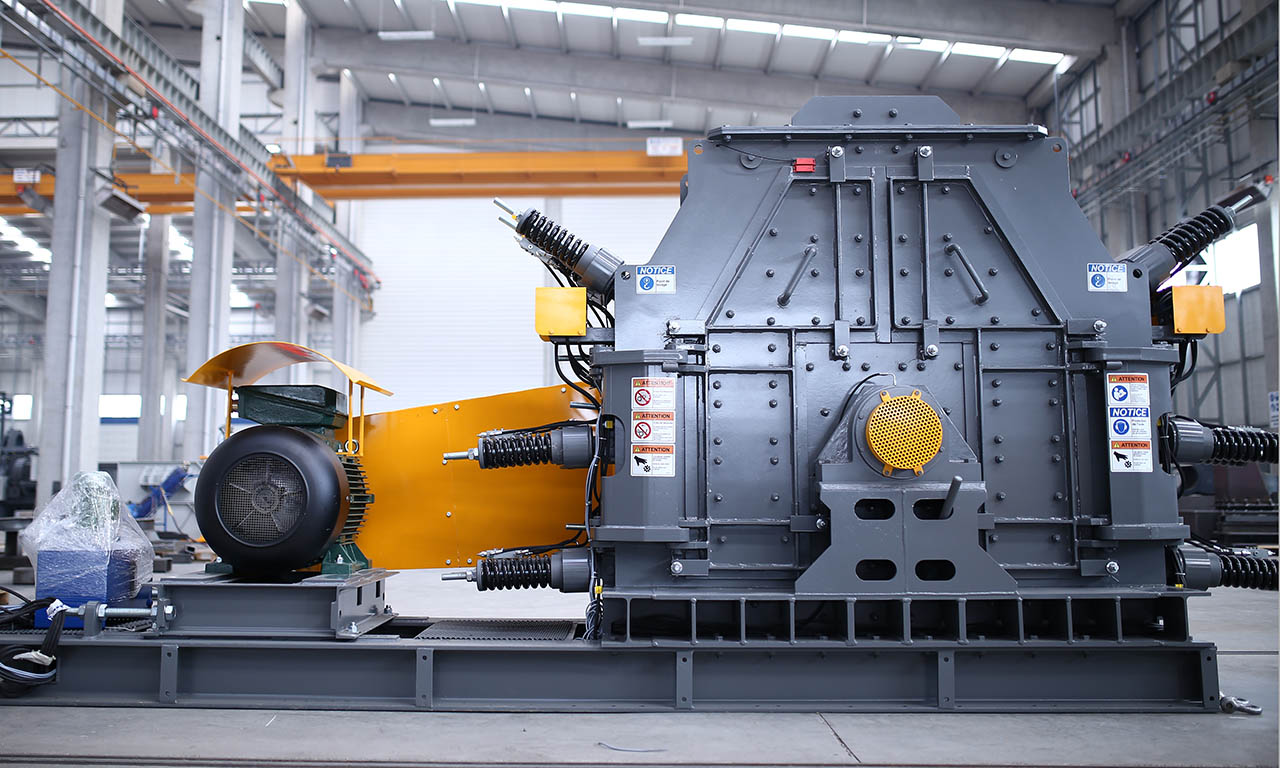

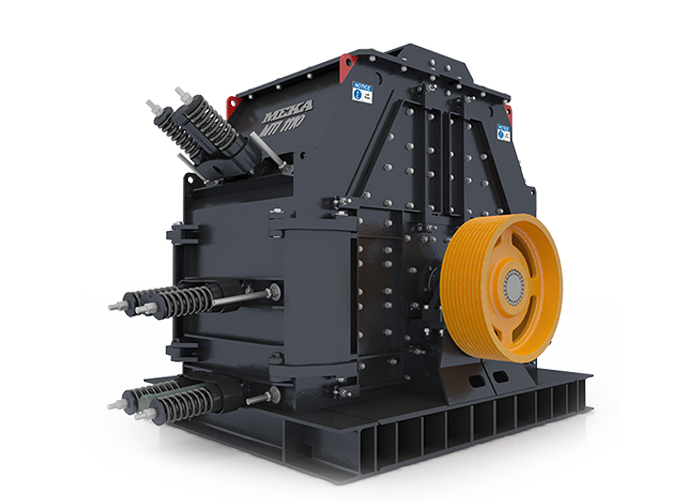

Tertiary Impact Crusher

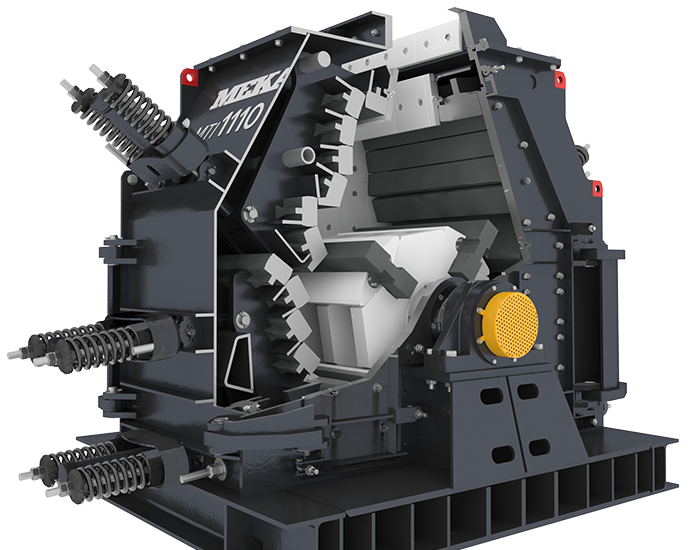

Tertiary impact crushers are manufactured with different rotor sizes and the required motor power is selected according to the application. The strength of Tertiary impact crushers (MTI) makes them ideal for every kind of application in many different configurations. Tertiary impact crushers (MTI) have demonstrated their effectiveness in many missions from crushing low abrasive materials to industrial applications and recycling.

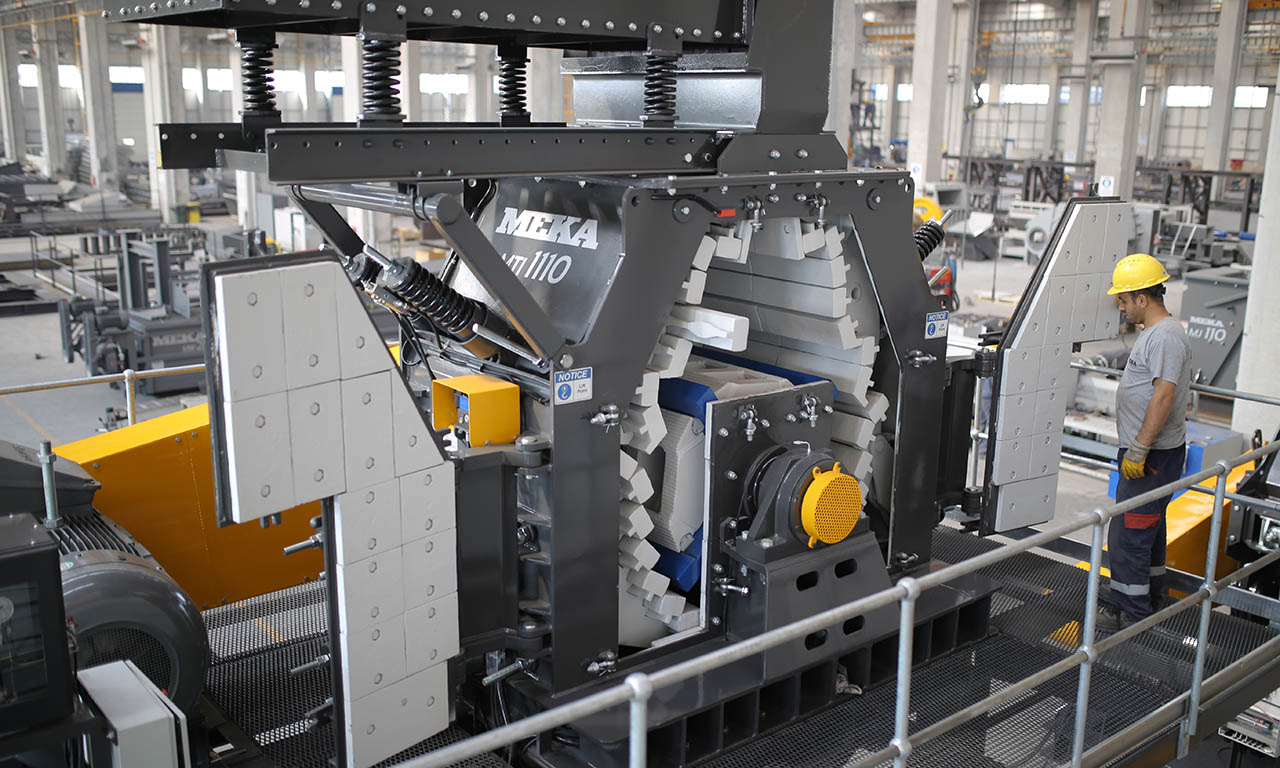

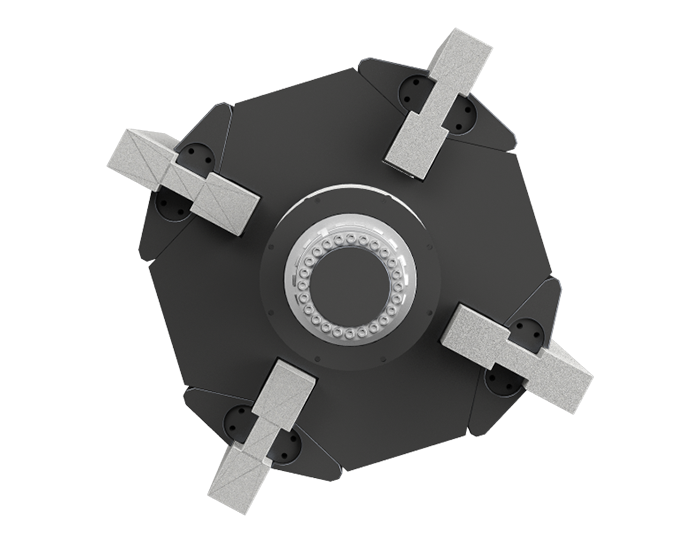

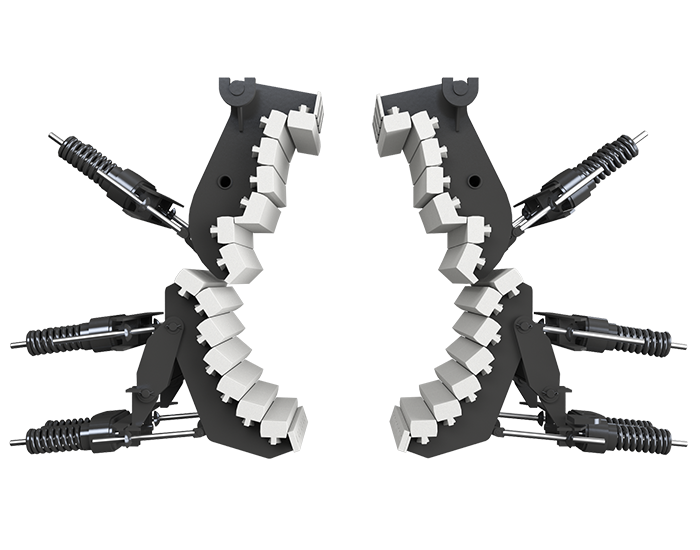

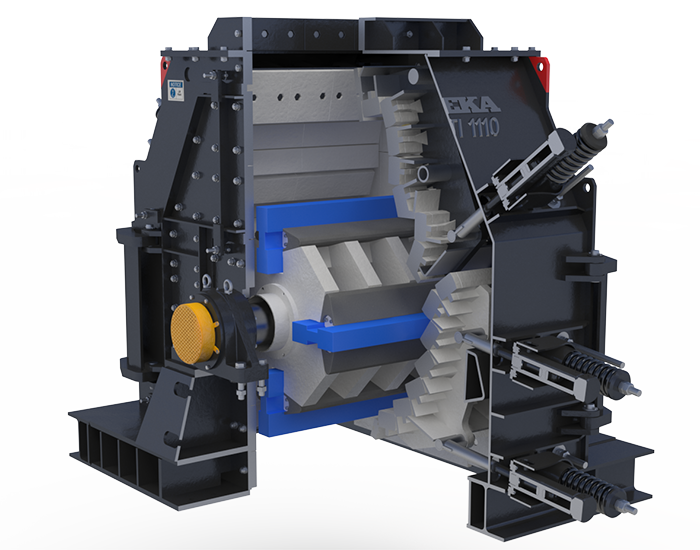

MEKA’s product range includes 2 different designs of tertiary impact crushers. MTI 1105-1110-1115 models are with 4 blowbars mounted on a circular shaped rotor and MTI 1307-1314 models are with 3 blowbars mounted on a oval shaped rotor.

Applications

QUARRIES

- Production of aggregates for concrete and asphalt plants,

- Production of manufactured sand,

- Shaping of flaky aggregates to obtain cubical aggregates,

INDUSTRIAL MINERALS

- Production of fine material with minimum capital and operational costs,

- Excellent particle shape down to micron sizes,

RECYCLING PLANTS

Why MEKA Tertiary Impact Crusher?

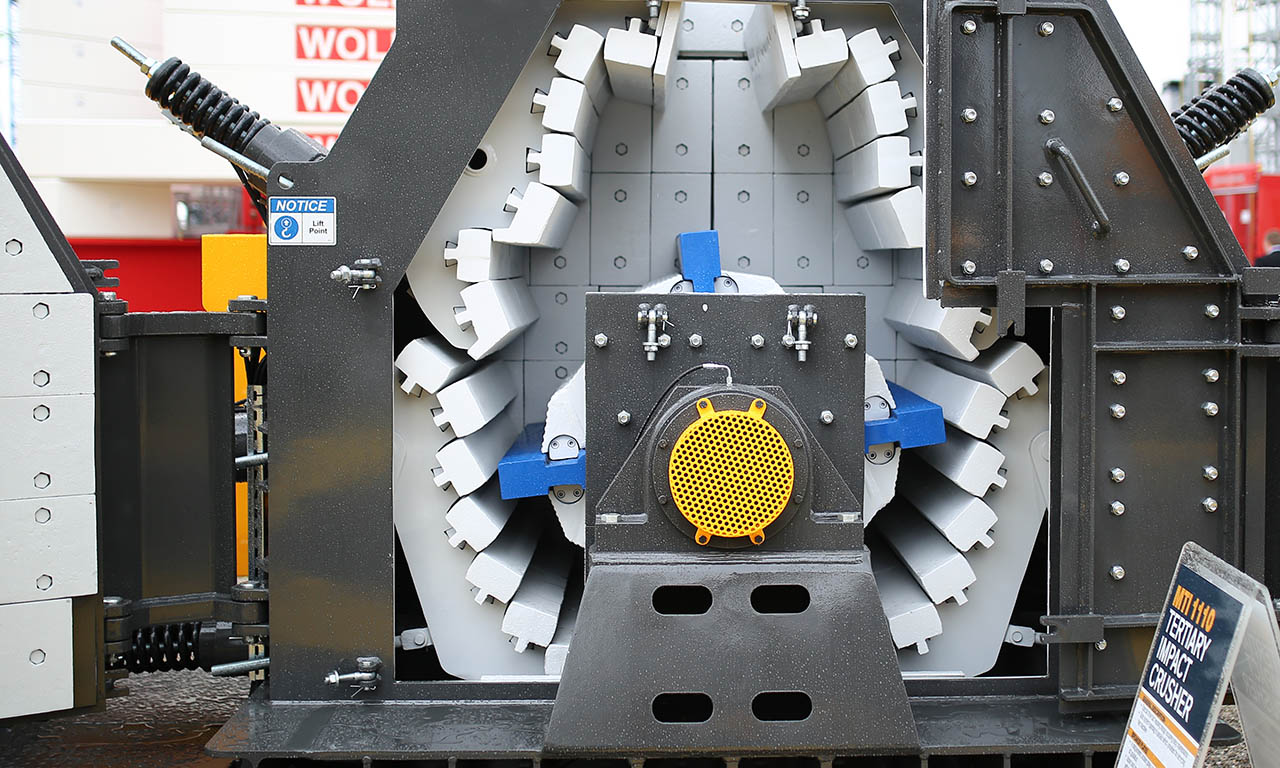

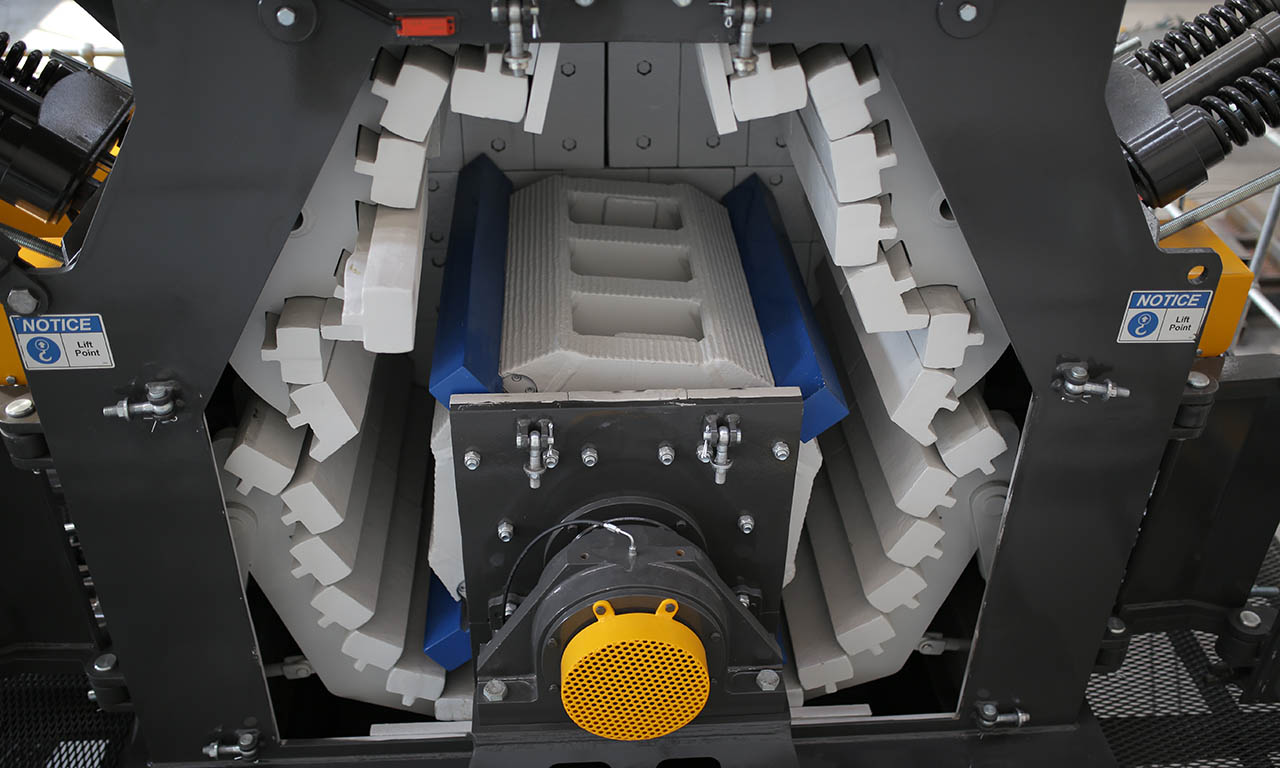

Symmetric Crushing Chamber Allows for better utilization of wear parts

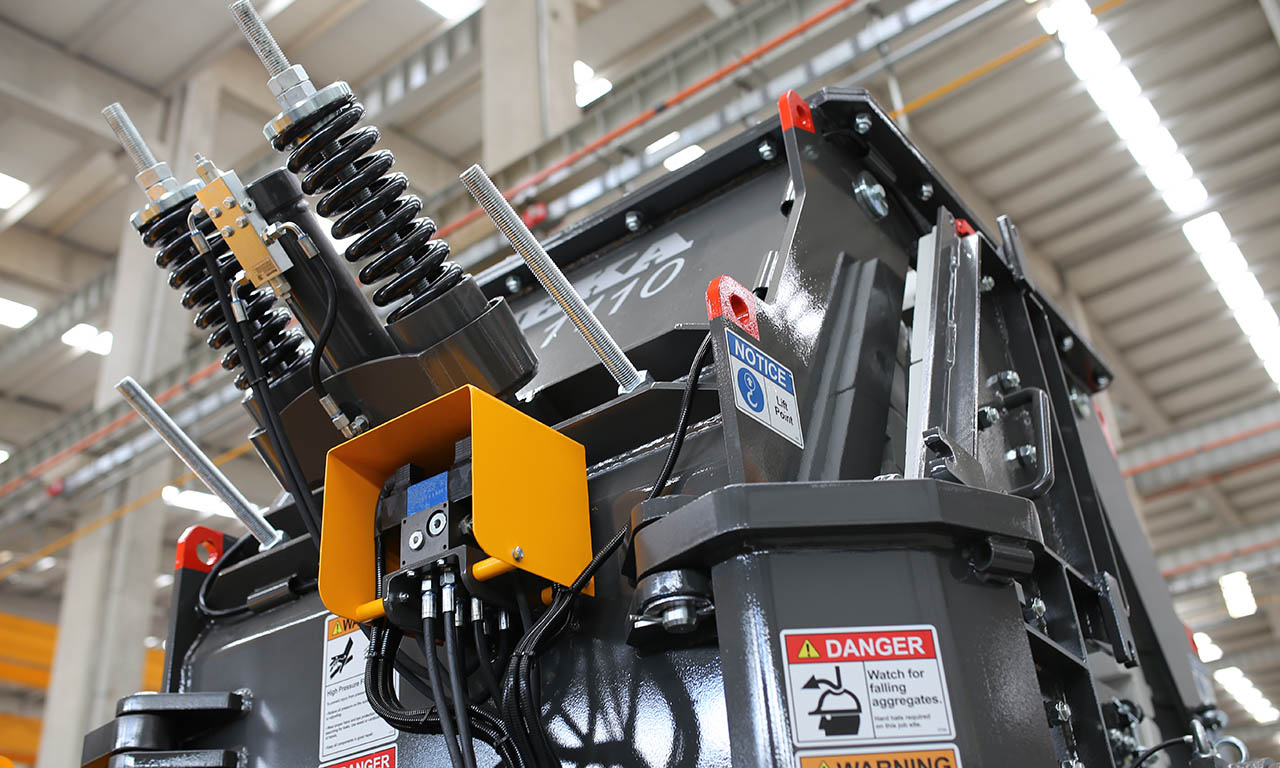

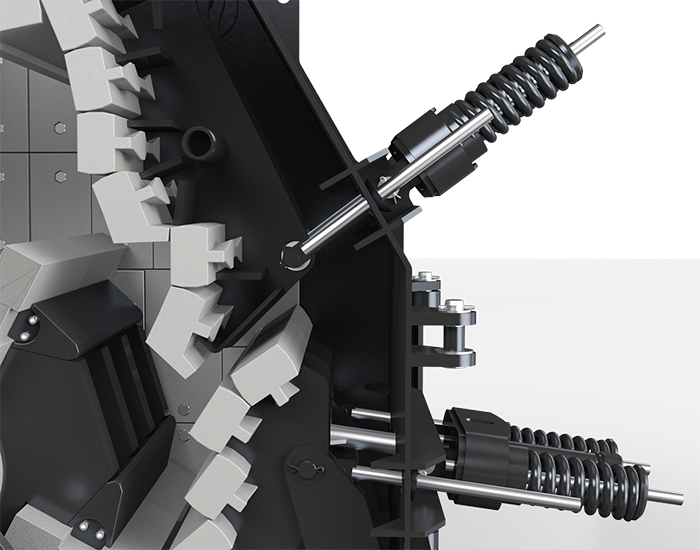

The rotors in our MTI Series crushers are designed to operate in both directions, so when the wear parts are worn out for one side of the crusher, the operators can change the rotor’s operating direction to the other side. This method decreases inventory costs for clients by reducing maintenance requirement time and parts cost.

High-Speed Rotor Produces More Fines

The rotor with high inertia improves reduction ratio and provides stability in the process, reducing energy consumption and increasing long-term performance.

Manufactures sand from limestone and dolomite

High quality and cubical shape products with low filler content

Upto 150mm feed size

Heavy rotor and crushing chamber design in addition to materials selected for their outstanding wear resistance further reducing operating and wear costs.

MEKA Tertiary Impact Crusher Advantages

-

MEKA Tertiary Impact Crusher Download Catalogue

Tertiary Impact Crusher Technical Specifications

MTI 1105 |

MTI 1110 |

MTI 1115 |

MTI 1307 |

MTI 1314 |

|

| Rotor Diameter (mm) Rotor Diameter (inch) | 1100 43 | 1100 43 | 1100 43 | 1286 51 | 1286 51 |

| Rotor Width (mm) Rotor Width (inch) | 500 20 | 1000 39 | 1500 59 | 655 26 | 1355 53 |

| Feed Opening (mm) Feed Opening (inch) | 520x310 20x12 | 1020x310 40x12 | 1520x310 60x12 | 690x210 27x8 | 1390x210 55x8 |

| Maximum Feed Size (mm) Maximum Feed Size (inch) | 150 6 | 150 6 | 150 6 | 90 6 | 90 6 |

| *Capacity (mtph) *Capacity (stph) | 100-120 110-130 | 220-250 240-275 | 280-320 310-350 | 100-120 110-130 | 220-250 240-275 |

| Power (kW) Power (HP) | 110 150 | 200-250 275-340 | 315 430 | 90-132 125-180 | 160-250 220-340 |

| **Weight (kg) **Weight (lbs) | 8750 19290 | 14000 30860 | 17470 38510 | 8400 18520 | 13480 29720 |

*For material weighing 1.6 t/m³ or 100 lbs/ft³. Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture content, crushability of the material, crusher rpm, installed power and the crushing circuit design.

** Weights shown do not include drive motor package, support legs, maintenance platform, inlet and outlet chutes.

What is Tertiary Impact Crusher?

A tertiary impact crusher is a type of crusher used in the tertiary stage of crushing and is used to produce cubical shaped aggregates and sand.

How Does Tertiary Impact Crusher Work?

The materials are crushed by the impact force generated by the blowbars mounted on a rotor. With the impact of the material on the blowbars on the rotor, the material hits the opposite breaker bars and a secondary crushing takes place. Unlike secondary and primary impact crushers, the rotor of the tertiary impact crusher can rotate in both directions.

Tertiary Impact crusher is used in the tertiary stage of the crushing process for soft and non or less abrasive materials. They produce cubical and high percentage of end products, and sand production rates in the end product are also very high.