Simply fill out the form to review our comprehensive catalog of product solutions for crushing, screening, and mining equipment.

DISCOVER MORE

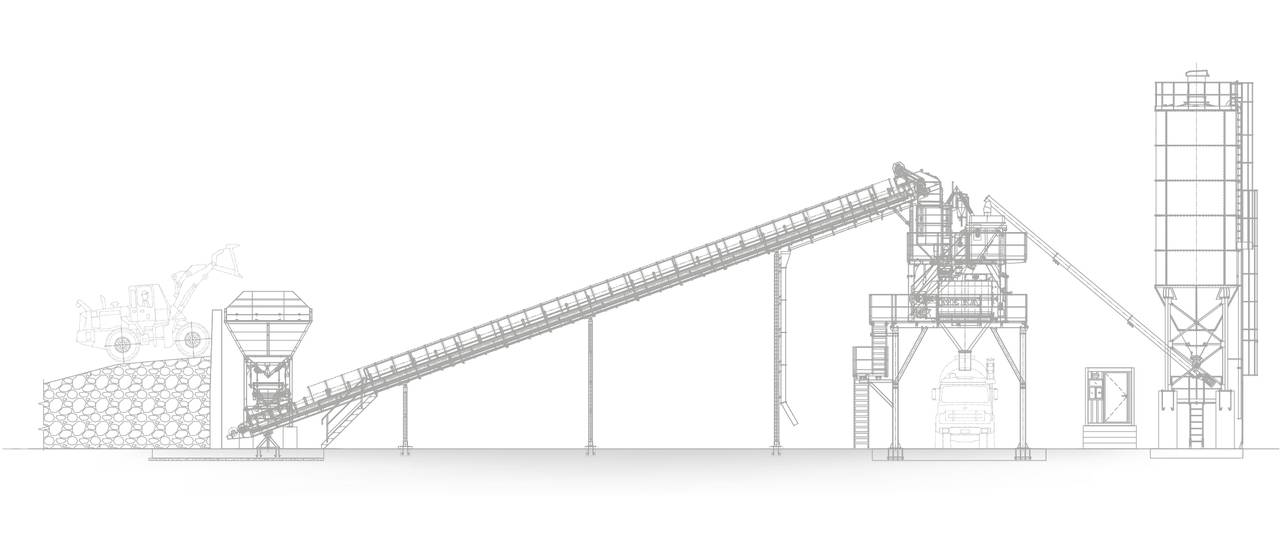

The K135, a powerful representative of our stationary concrete batching plant range, sets industry standards with its renewed design and enhanced productivity features, further boosting your operational efficiency.

The K135 Stationary Concrete Batching Plant, known for its high capacity and continuous ready-mixed concrete production performance, is the top choice for those who prioritize both capacity and efficiency. Its redesigned structure allows operation in a more compact installation area.

Equipped with a 3.0 m³ capacity MEKA twin-shaft mixer, the K135 is a durable investment, featuring hot-dip galvanized weighing units, bunkers, and plant components for enhanced longevity and reliability.

Your concrete batching plant investment purpose and your expectations from the plant may vary different.

Whether you are a ready-mixed concrete producer, a contractor or a manufacturer of precast building elements, we have a very strong R&D team and international experience since 1987 to design and manufacture the most suitable batching plant for your needs.

Here are some of our customization options. Our technical sales team can support you in assiting the appropriate layout and equipment to optimize your productivity and business.

Simply fill out the form to review our comprehensive catalog of product solutions for crushing, screening, and mining equipment.