Are you still throwing away your concrete waste or faulty production? As the importance of environmental responsibility of businesses increases, certain standards are being introduced in production in order to leave a cleaner world to future generations. In addition, in today's world where production costs are gradually increasing, operational efficiency has become the most important heading of sustainable activities. With the MEKA recycling unit, components such as aggregate, sand and water in concrete can be separated and reused in production.

DISCOVER MORE

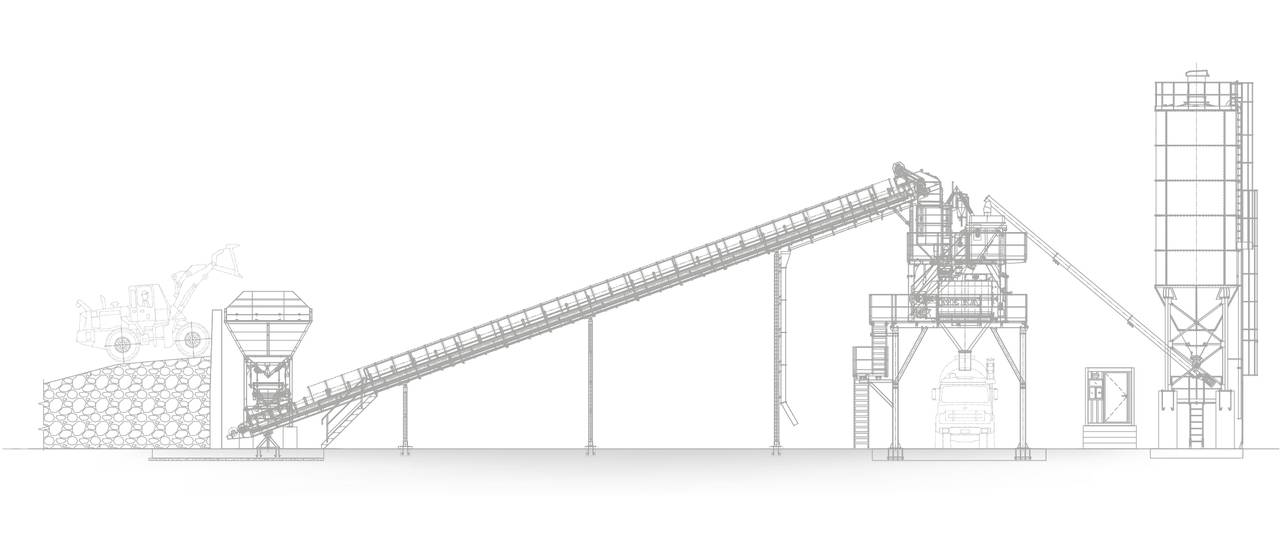

Special reinforcement and applications for quality and uninterrupted concrete production in harsh winter conditions: Steam pipes placed inside the aggregate bunker Complete enclosure of the main unit with 40 mm thick insulated panels Complete covering of the bottom of the aggregate bunker with 40 mm thick insulated panels Retractable electric gates on the aggregate bunker Steam generator (high performance steam generators that can run on diesel, natural gas or both, selected according to the plant capacity)

The top and sides of the aggregate bunker can be covered with trapezoidal sheets to both protect from environmental influences (rain, snow, wind, etc.) and to minimize the impact of dusting on the environment. The four sides and top of the main unit, which contains the mixer, cement-water-additive scales and aggregate waiting bunker, can be covered with trapezoidal sheets. In this way, the main unit can be protected from environmental influences (rain, snow, wind, etc.).

You can improve the versatile production capacity of your batching plant thanks to the fiber feeding system that automatically feeds and doses steel or polyester concrete fibers used in the production of special quality concrete and is integrated with the plant automation.

DISCOVER MORE

- HYDRONIX brand Microwave moisture meter for aggregate bunker sand compartment. It precisely measures the moisture in the sand and ensures that less water and complementary sand is added by the amount of moisture measured by the automatic system.

- Aggregate Bunker bunker grates to be placed on top of the bunker with 100x 100 mm mesh width to prevent large stones from entering and damaging the system

- Water booster with STANDART brand pump that sends water to the water scale at the required flow rate and pressure (with double pump and single pump options)

- Mixer safety interlock can be added for more safety during maintenance. With this system consisting of two switches, the plant cannot be started unless the maintenance person stops the system completely and takes one switch on himself, preventing possible accidents.