What is Manufactured Sand?

What is Manufactured Sand?

Manufactured sand is also known as artificial sand and is generated through the crushing and screening of rock products, and therefore uses rock that can be used for other purposes such as concrete and asphalt aggregates, roadbases, armour rock, etc. It can range in size but typically passes through 7mm or 5mm screens. It is gradually becoming a substitute for natural sand, and the application of manufactured sand has become a global trend.Due to its manufacturing process, manufactured sand may contain large quantities of microfine particles (<63µm) and the produced sand can be washed and screened to remove any fine particles or impurities.

Why Manufactured Sand?

Sand is world’s second most consumed natural resource after water. Rapid urbanization and global population growth have created unbound demand for this limited natural resource.

With urbanization as key driving factor, construction industry has expanded considerably over the last few decades leading to overuse of river sand for construction purposes. This increasing discrepancy between the need for aggregates in the society and scarcity of natural sand due to exhaustion of resources and environmental considerations, has urged concrete manufacturers to look for a suitable and sustainable alternative fine aggregate. The economical and ecological alternative is manufactured sand.

Benefits of Manufactured Sand

• Sustainable alternative: Manufactured sand (M-Sand) provides a sustainable solution to the scarcity of river sand, reducing the strain on natural resources and protecting fragile ecosystems.• Consistent quality: M-Sand offers consistent and superior quality compared to river sand, as it is produced using advanced technology and precise manufacturing processes.

• Cost-effective: M-Sand is often more affordable than river sand, making it a cost-effective choice for construction projects.

• Reduced environmental impact: M-Sand production minimizes the need for riverbed mining, thereby preserving river ecosystems and reducing environmental degradation.

• Availability and accessibility: With the establishment of M-Sand units, there is increased availability of construction materials, reducing dependence on river sand and ensuring consistent supply for the industry.

Equipment Selection of Manufactured Sand Production

MEKA can provide several solutions to manufacture sand. By using the rightcrushing equipment, manufactured sand can be produced in a comparable way as sand is formed naturally. Choosing the right process design and the right crusher is essential to meet the necessary requirements.

Coarse crushing equipment for primary crushing

The coarse crushing equipment is generally a MEKA MJ Series jaw crusher or a MEKA MPI Series two-chamber primary impact crusher (suitable for medium hardness or soft materials).Medium crushing equipment for secondary crushing

For medium crushing, MEKA provides MCH Series cone crusher and MSI Series horizontal shaft impact crusher for customers to choose.Cone crusher: Mainly suitable for crushing rocks with high hardness and high abrasiveness index, with fewer powdered products.

Impact crusher: Mainly suitable for crushing rocks with medium or low hardness and abrasiveness index, with more powdered products.

Fine crushing equipment for tertiary crushing

Depending on the application, the type of material to be processed, the type of sand required, and the specifics to be meet, MEKA can propose the most suitable crusher for fine crushing such as horizontal shaft impactors (MTI Series) and vertical shaft impactors (MVI Series).

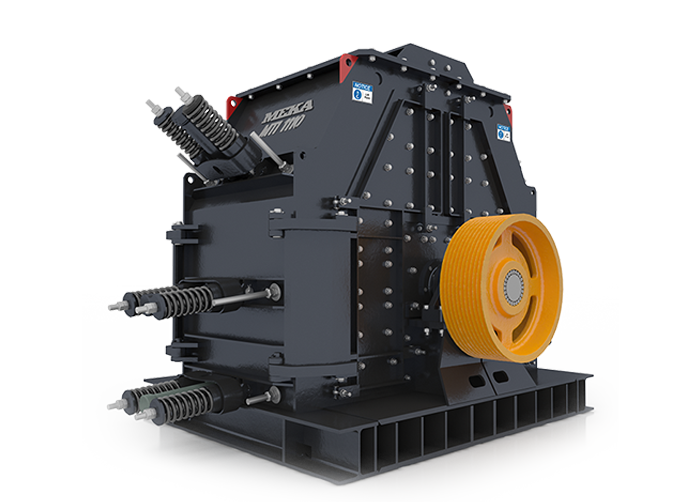

• Horizontal shaft impact crusher for sand making (MTI Series)

There are some recommendations for the use of MTI cushers in manufactured sand applications. Particle shape received from an MTI crusher is excellent, since it is more angular than rounded. As a process machine, MTI is not sensitive to fines in the feed and is a nearly ideal machine for closed circuits. The MTI crushers are reliable machines and not sensitive to feed fluctuations and sticky materials.

MTI’s simple design shows a high reduction ratio, works perfect with less abrasive material and is an easy-to-use process machine. With a wide product range, throughput capacities of 100-320 mtph can be achieved.

MEKA MTI Series Tertiary Impact Crusher

• Vertical shaft impact crusher for sand making (MVI Series)

MVI Series vertical shaft impact crusher produces the best particle shape for concrete sand, but it may lack some particle sizes in the final product gradation to meet the concrete specification curve depending on the application and the type of rock processed. It may also produce excess of fines –63µm. In asphalt sand, it produces great quality product; the anvil ring configuration could be the best one to use in this type of application if the feed material characteristics allow a cost-effective operation.

These crushers are offered in a variety of enclosed rotor or open table configurations and are convertible between three types of crushing chamber designs for maximum flexibility. Configuration options include enclosed rotor and rock shelf (ROR), enclosed rotor and anvil ring (ROS) and open table and anvil ring (SOS). This feature maximizes flexibility and allows the crusher to be configured as needed with the highest performance possible for producing sand.

MEKA MVI Series Vertical Shaft Impact Crusher

Why Need a Washing System For Manufactured Sand?

Due to its manufacturing process, Manufactured Sand may contain larger quantities of microfine particles than natural sand. Micro fines classify as particles finer than –63µm. Concrete producers need a very specific and consistent gradation in their sand that is not typically satisfied by the fines produced in conventional rock crushing. Usually, coarser particles are abundant, there is a shortage of material in the crucial 150µm–1mm range, and an excess of –63µm or filler.

Micro fines can increase the water demand in concrete, thus lowering its strength. They can also reduce workability and retention of workability even when a high-range water reducer (HRWR) is in the mix design. The added fines’ surface area requires more cement paste to maintain pumpability and finishability.

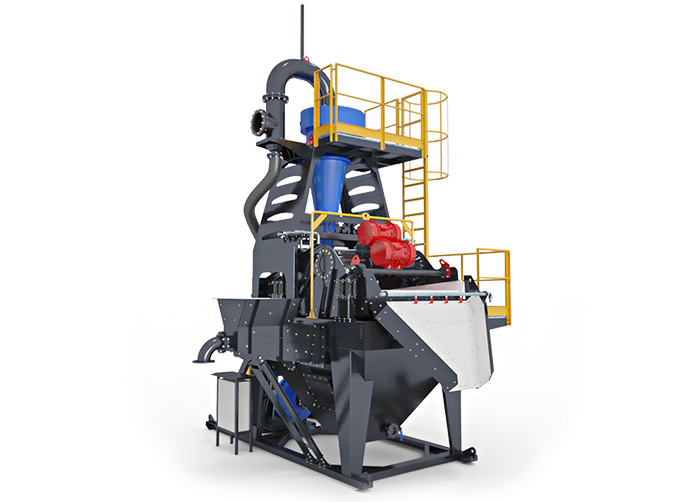

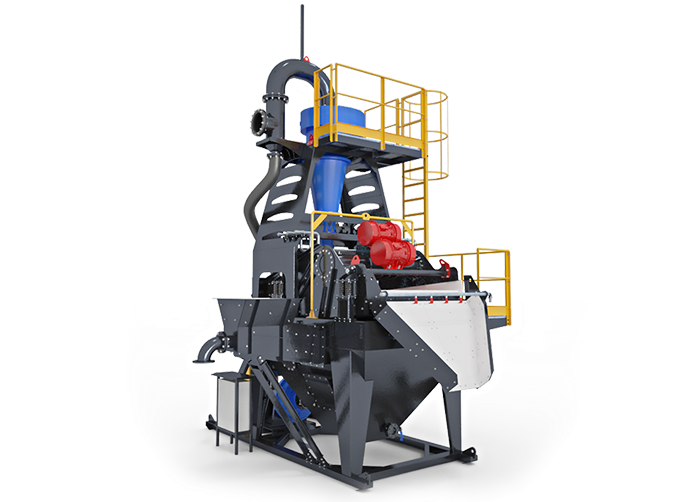

MEKA’S Solution for Treatment of Manufactured Sand (MCSP PLANTS)

Due to the level of variation in crusher dust from one situation to another, each plant is custom built to deal with the specifics of your material and your desired final product specifications. This involves extensive material analysis in the first instance to determine the volume of commercially viable product that can be recovered from your crusher dust.

Then we set about the design and delivery of a crusher dust washing plant which will maximise production of manufactured sand and minimise waste from your rock crushing operations.

MEKA’s all-in-one sand washing, classification and dewatering system, MCSP uses hydrocyclone technology to deliver unparalleled control of silt cut points and increases product yield. Efficient dewatering screen means the resulting sand is ready for use in concrete production straight off the belt conveyor.

MEKA’s MCSP Series compact sand plants efficiently deal with a number of issues for our customers including;

• Efficient removal of the –63µm material, typically 15-20% of the feed.

• Crusher dust is typically very low in the +63µm to -600µm range, so it is essential that none of this material is lost during processing.

• Reduction of clay content and other expansive materials in the fines fraction, producing fine material conforming to methylene blue absorption test.

• Where there is clay present in the crusher dust, we can provide attrition cell options to allow for effective removal of this clay from your final washed sand product.

MEKA MCSP Series Compact Sand Plant

Waste Water and Sludge Treatment Equipment

After washing the sand and gravel aggregate, the mud containing waste water need to be treated to achieve discharge standard. After the investigation of the mud containing waste water, we can adopt thickener group and filter press unit to treat the waste water and mud, which can avoid the shortcomings of direct discharge of sludge waste into the sedimentation tank, such as large area and difficult to clean up the sedimentation tank.

Where can I buy equipment to manufacture sand?

Would you like to buy equipment to manufacture sand? Contact MEKA GLOBAL today. We have experts on hand to help you find the best equipment for your needs and budget. Want to upgrade your equipment for more efficient crushing, screening and washing? We can help you with that too with our full range of feeders, crushers, screens, wet processing equipment and more.