What is Primary Crusher?

What is Primary Crusher?

The primary crushing stage is the first step in the rock crushing process. At this point, large rocks are reduced to smaller rocks by a crusher. The primary crushing stage is important because it prepares the rocks for further processing. By reducing the size of the rocks, the equipment required for the next step can handle smaller rocks more efficiently. This saves time and money during the processing stages.

The primary stage of rock crushing is important because it sets the tone for the rest of the process. If the wrong equipment is used, it can result in a lot of wasted time and money. That’s why it’s important to use a crusher that is suited for the type of rock you are dealing with.

For example, if you are dealing with softer rock, such as limestone, you would want to use a impact crusher. These types of crushers are able to break down the rocks more easily. However, if you are working with harder rock, such as granite, you would want to use a jaw crusher. These types of crushers are able to break down tougher rocks more effectively.

Types Of Crushers To Use During The Primary Crushing Stage

When it comes to crushing rocks, there are a variety of different methods that can be employed. Each has its own advantages and disadvantages, and each is better suited for different types of rock. Here, we take a look at the two most common types of crushers used during the primary stage: jaw crushers, impact crushers.

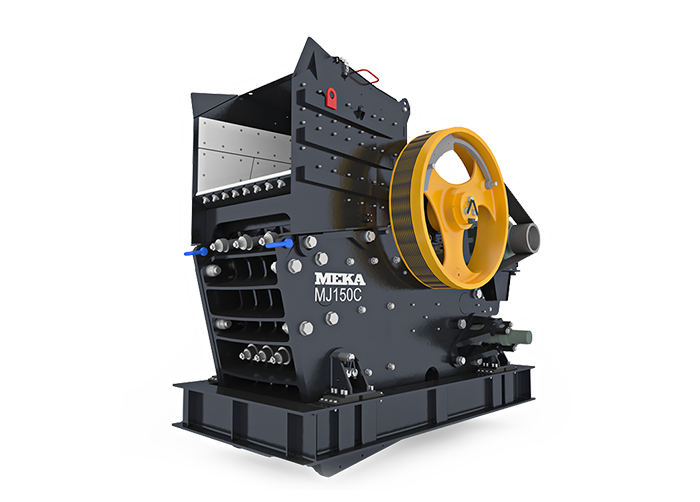

Jaw Crushers

The most common primary Crusher is a jaw Crusher. A jaw Crusher is made up of two big plates that are held in a V-shape. One side of the jaw moves back and forth, and the other side stays fixed in place, this is the breaking surface. As the material is fed into the Crusher, it is pushed by the swinging plate against the part of the jaw that doen’t move. This pressure break sup the rocks until they are small enough to pass through the discharge gap.

The distance between the jaw plates can be made smaller or larger depending on the size of the material you want to process. When used as a primary crusher, the main aim is to get the rocks to a size that the secondary cusher can crush with ease.By keeping the discharge gap wide, you will be able to crush your material and increase your production.

Advantages:

• Jaw crushers are powerful primary crushers and can be used for crushing of very hard rocks. . They’re used in mining, pit and quarry, construction aggregates, and demolition recycling.

• Jaw crushers are typically very reliable due to their simple design.

• They are also quite efficient at crushing material, meaning that they save on energy costs in the long run.

Disadvantages:

• Aggregate it produces has a flat, slabby particle shape. For most construction applications, cubical shape is more ideal as it has better compaction properties for road construction and binds better with cement to form strong concrete material. Since the output material is oddly shaped, they have to be followed by a secondary Crusher.

• Reduction ratio is lower when compared to impact crushers.

MEKA MJ Series Jaw Crusher

Impact Crushers

Impact crushers are widely used type in the primary rock crushing stage. They can crush various large types of rocks, including limestone, coal, and other types of minerals. Impact crushers also have a high ratio of reduction and can easily crush large lumps of material.

The basic working principle of an impact crusher is that material is fed into a high-speed rotating rotor, which flings the material around at high speeds between a series of spinning blowbars and the breaker plates. The numerous collisions taking place inside the impact chamber causes the material to break apart. Upon reaching the specified size, the crushed material will be discharged.

Advantages:

• Capable of delivering a much more homogenous, consistent and cubical end product. This makes impact crushers favourable when the final result needs to be a saleable commodity.

• Are also quite versatile and can process a variety of different materials, including concrete, soft rock, and even asphalt.

• Have a fairly large feed inlet and sizeable crushing chamber and, if used with less abrasive materials, can lead to an economical and reliable crushing operation.

• Additionally, impact crushers have a higher reduction ratio when compared to jaw crushers.

Disadvantages:

• Typically require more maintenance than jaw crushers, especially if crushing hard and abrasive materials. This is because the material in an impact crusher is constantly colliding within the crusher at high velocities to break the rock apart. This contributes to higher operational costs due to higher wear rates when compared to jaw crushers, although modern wear-resistant materials have made impact crushers more popular.

• When crushing very soft materials, excess fines can be produced. This contributes to more potential dust pollution as well, which can be an occupational health and safety concern if not mitigated through the implementation of dust control measures.

MEKA MPI Series Primary Impact Crusher

How to Choose the Right Primary Crusher

Choosing the right size and type of primary crusher is really important if you want to get the best output and performance from your crushers. There are a few things to keep in mind when trying to decide on the right primary crusher for your business. Here are some key points to think about;

• What do you need your crusher to do?

• What type of materials will you be working with, is it hard rock or soft rock, big pieces or smaller pieces?

• Where will you be using your crusher, and do you need to move it on wheels?

• Input to output ratio you need?

Where Can I buy a Primary Crusher?

Would you like to buy a primary jaw crusher or impact crusher? Contact MEKA GLOBAL today. We have experts on hand to help you find the best equipment for your needs and budget. Want to upgrade your equipment for more efficient crushing? We can help you with that too with our full range of feeders, crushers, screens and more.