Applications

Why MEKA Portable Cone Crushers?

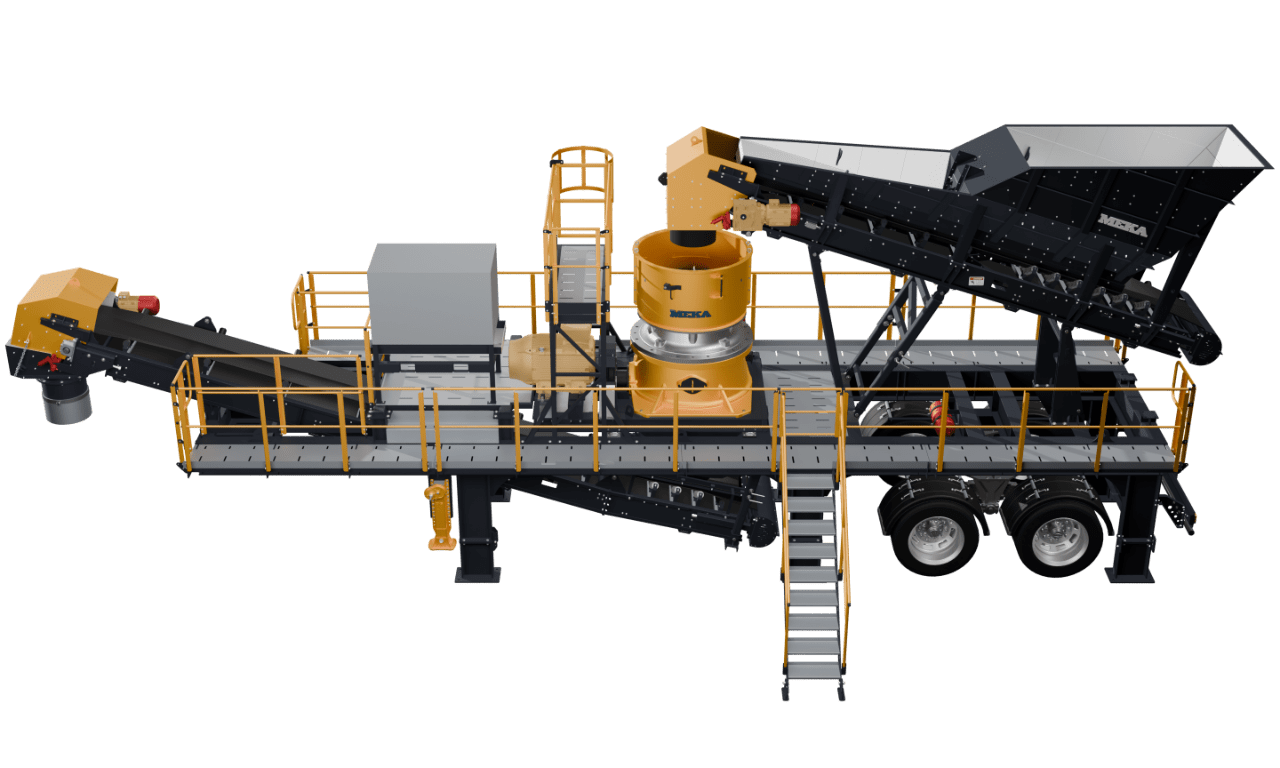

High capacity and excellent end product cubicity

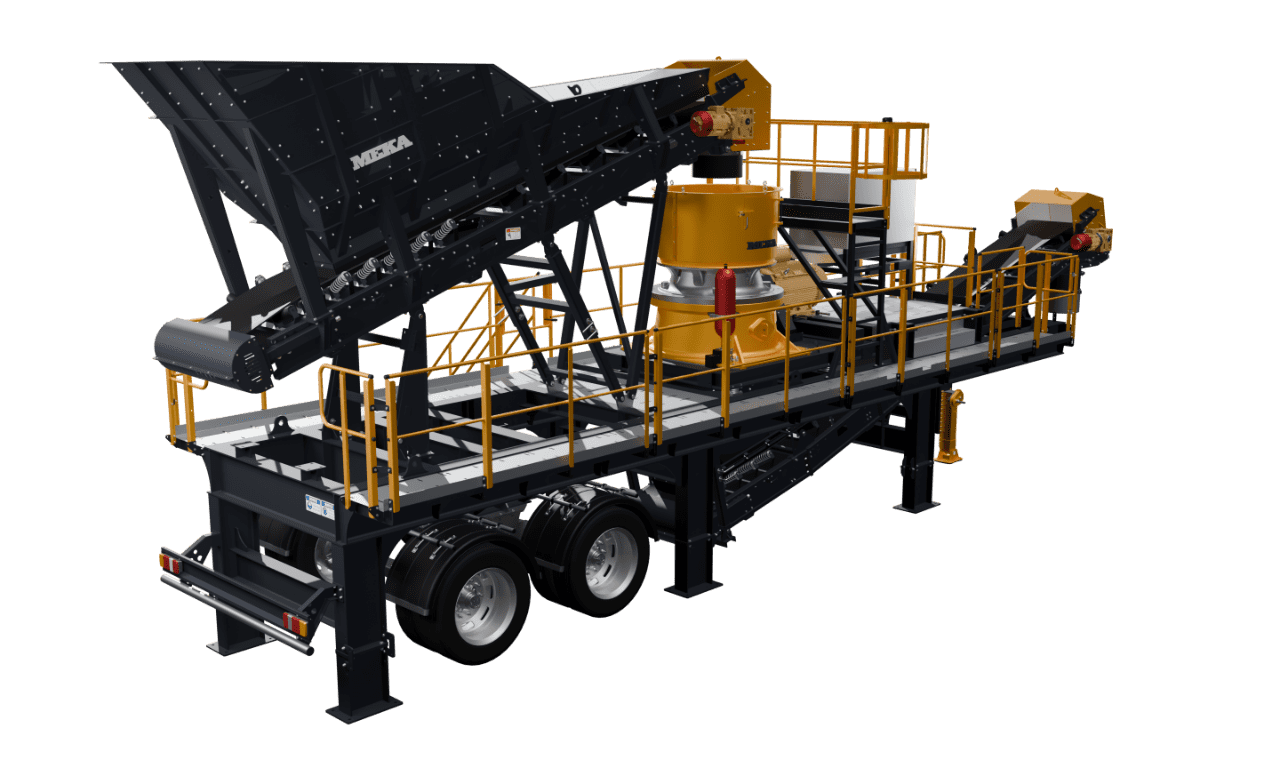

Hydraulic Closed Side Setting System and overload protection for maximum uptime

Choice of several chambers, throws and settings for a wide range of applications

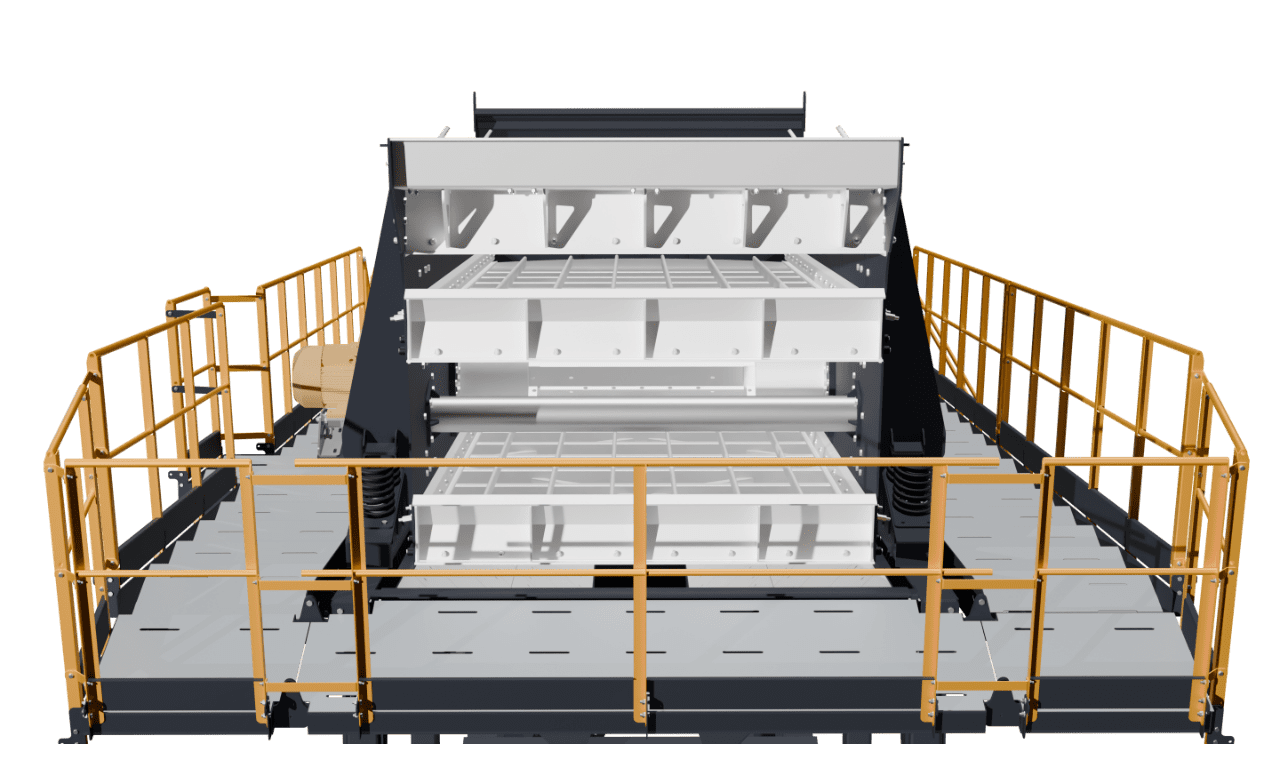

Highly efficient and accurate on board screen for product classification

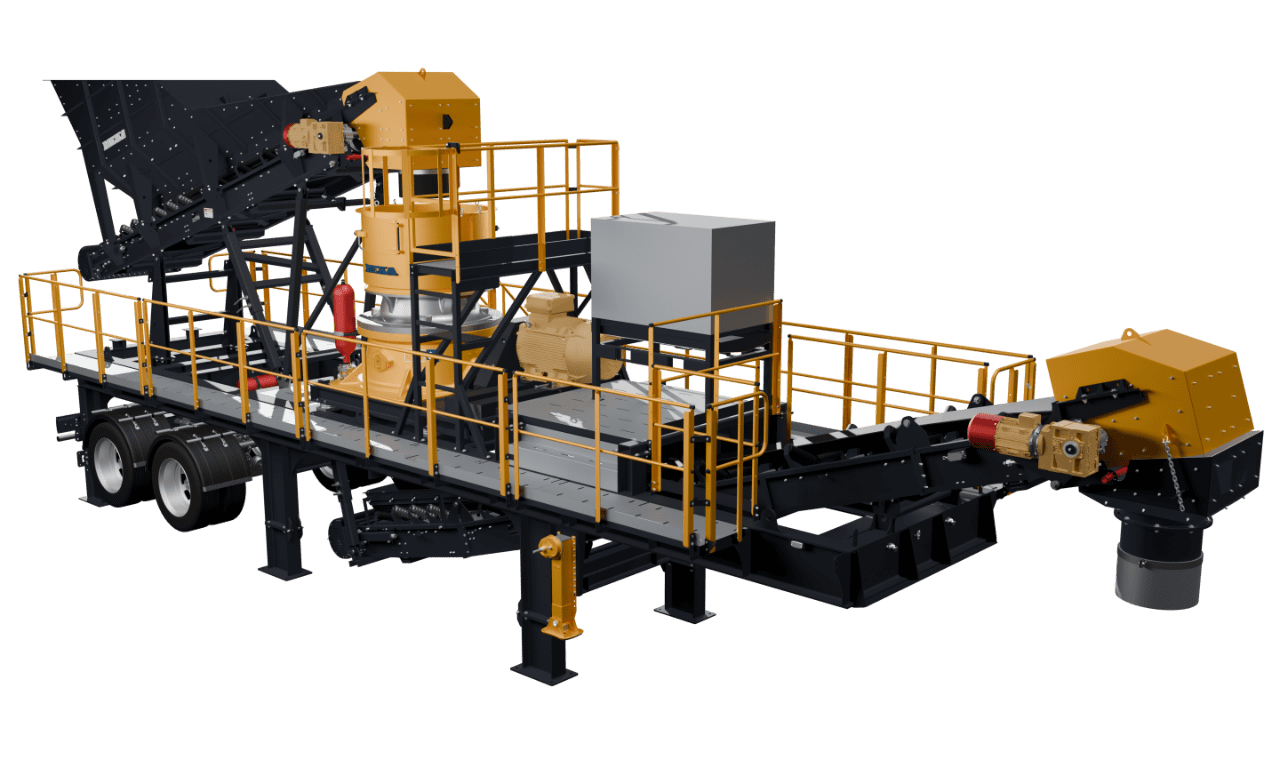

Self contained electrical switchgear cabinet mounted on the semi-trailer, with controls for screen and crusher,

Electrical switchgear cabinet can be located on the ground during operation,

2” / 3 ½” King-pin, double or triple-axle bogie with air-brakes, ABS and travel lights, mudflaps.

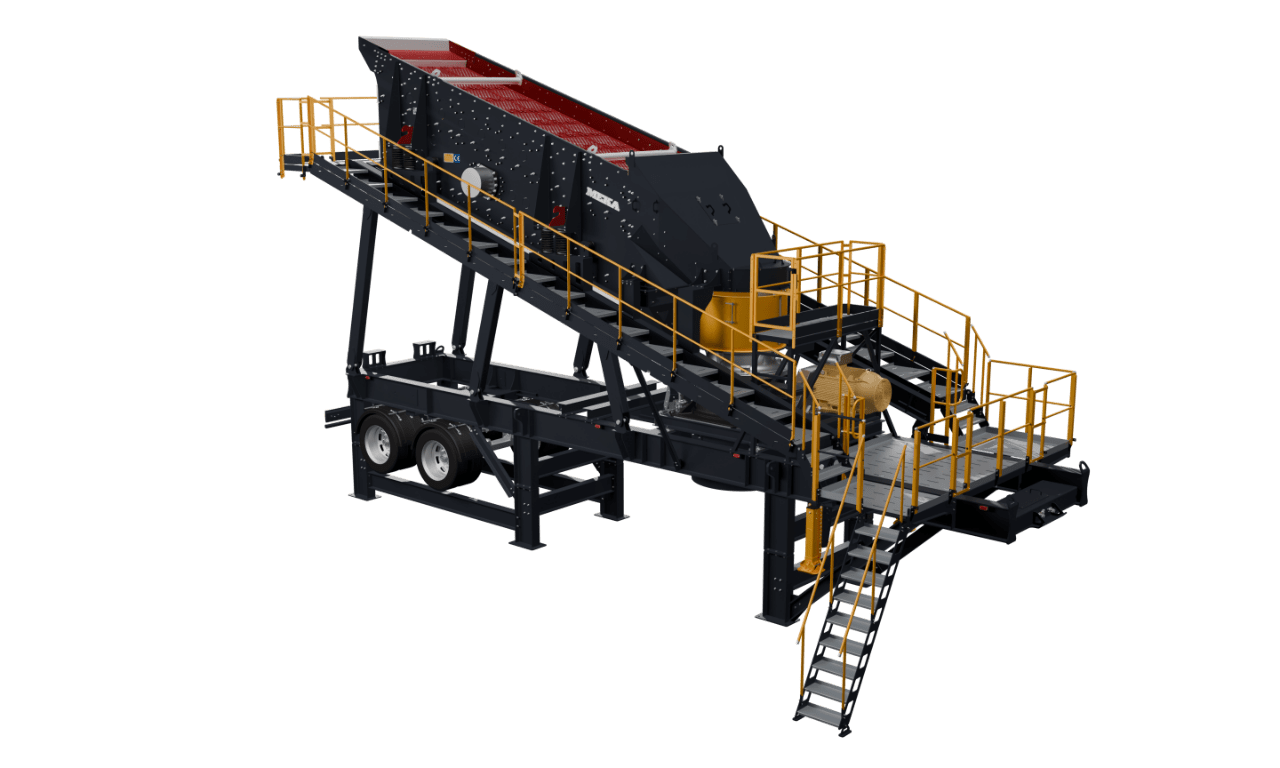

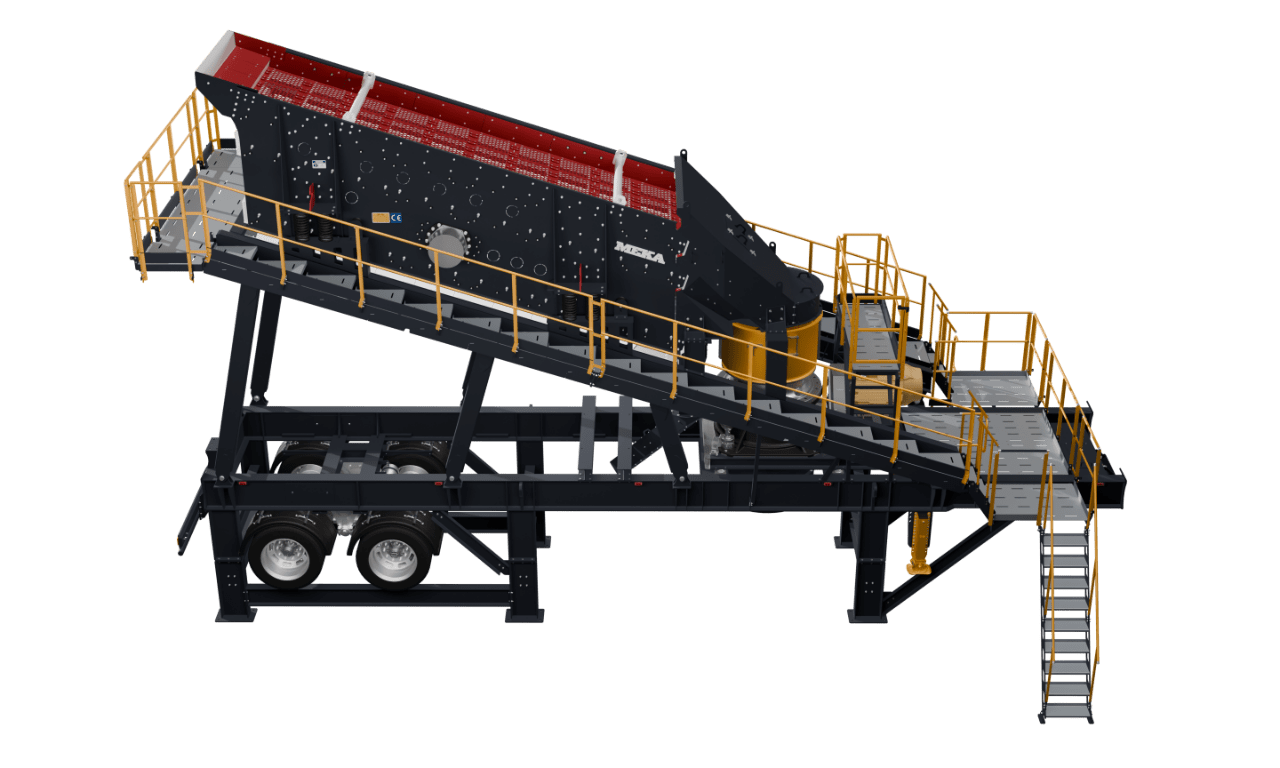

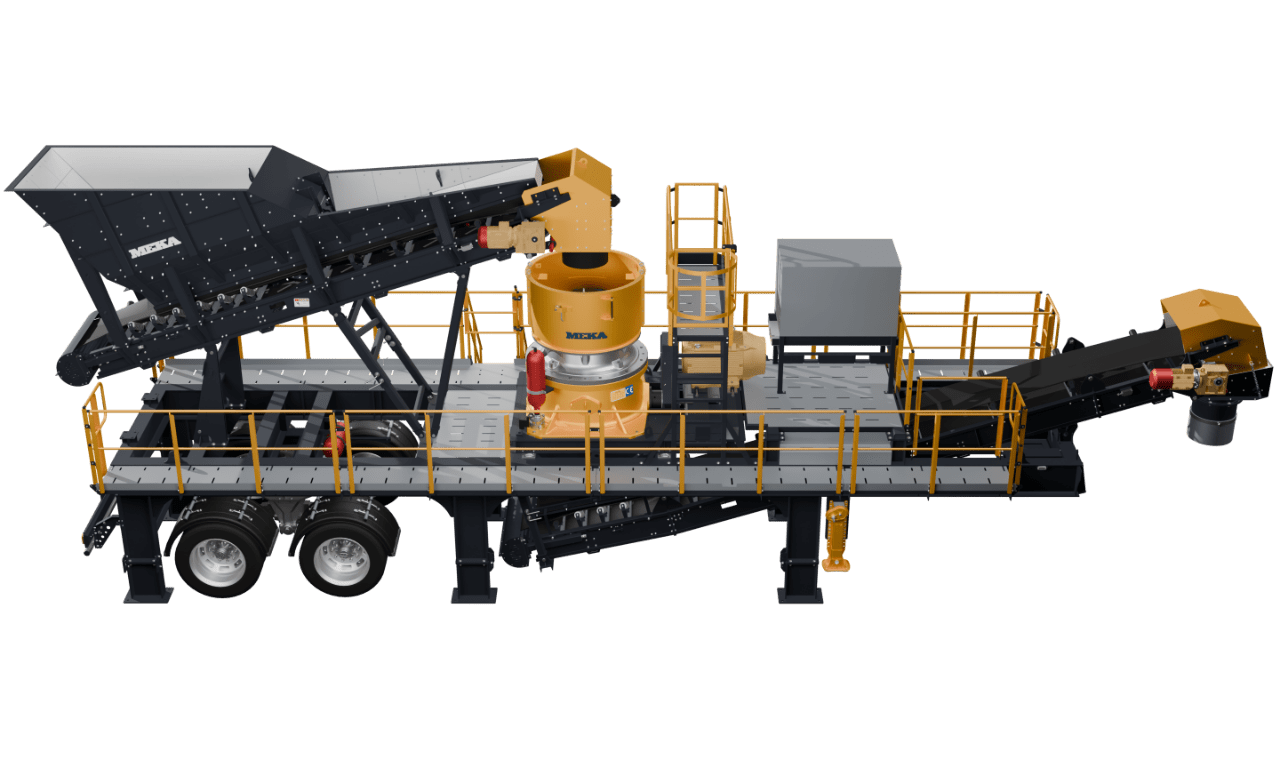

Portable Cone Crushers Gallery

Portable Cone Crushers Technical Specifications

MP 1150C-S |

MP 400CH-S |

||

| SCREEN | |||

| Model | MS 2050X3 | MS 1850X4 | |

| Width | 2 m | 1,8 m | |

| Length | 5 m | 5 m | |

| Decks | 3 | 4 | |

| Motor Power | 22 kW | 22 kW | |

| CONE CRUSHER | |||

| Model | MCH 1150 | MCH 400 | |

| Maximum Feed Size | 210 mm | 210 mm | |

| *Capacity | up to 340 mtph | up to 340 mtph | |

| Motor Power | 200kW (50 Hz) | 250kW (50 Hz) | |

| TRANSPORT DIMENSIONS | |||

| Length | 12.9 m | 12.7 m | |

| Width | 3.5 m | 3.2 m | |

| Height | 4.3 m | 4.3 m | |

| **Weight | 39 800 kg | 43 000 kg | |

| OPERATING DIMENSIONS | |||

| Length | 12.3 m | 12.3 m | |

| Width | 5.4 m | 5.4 m | |

| Height | 7.2 m | 7.2 m | |

*For material weighing 1.6 t/m³ or 100 lbs/ft³. Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture content,crushability of the material, crusher rpm, installed power and the crushing circuit design.

**Weights shown do not include drive motor package, support legs, maintenance platform, inlet and outlet chutes

What is Portable Cone Crusher?

The Portable Cone Crusher with inclined screen plant is a wheel mounted unit which consist of cone crusher and 2-3-4 decks inclined screen on the same trailer chassis.

Compact design : On the same chassis with the screen, is ready to produce the products on its own or can be easily adapted to a plant. Ready for operation: Can be commissioned and started up quickly

No concrete work: No need for excess concrete and site preparation Quick and easy site change for another project .