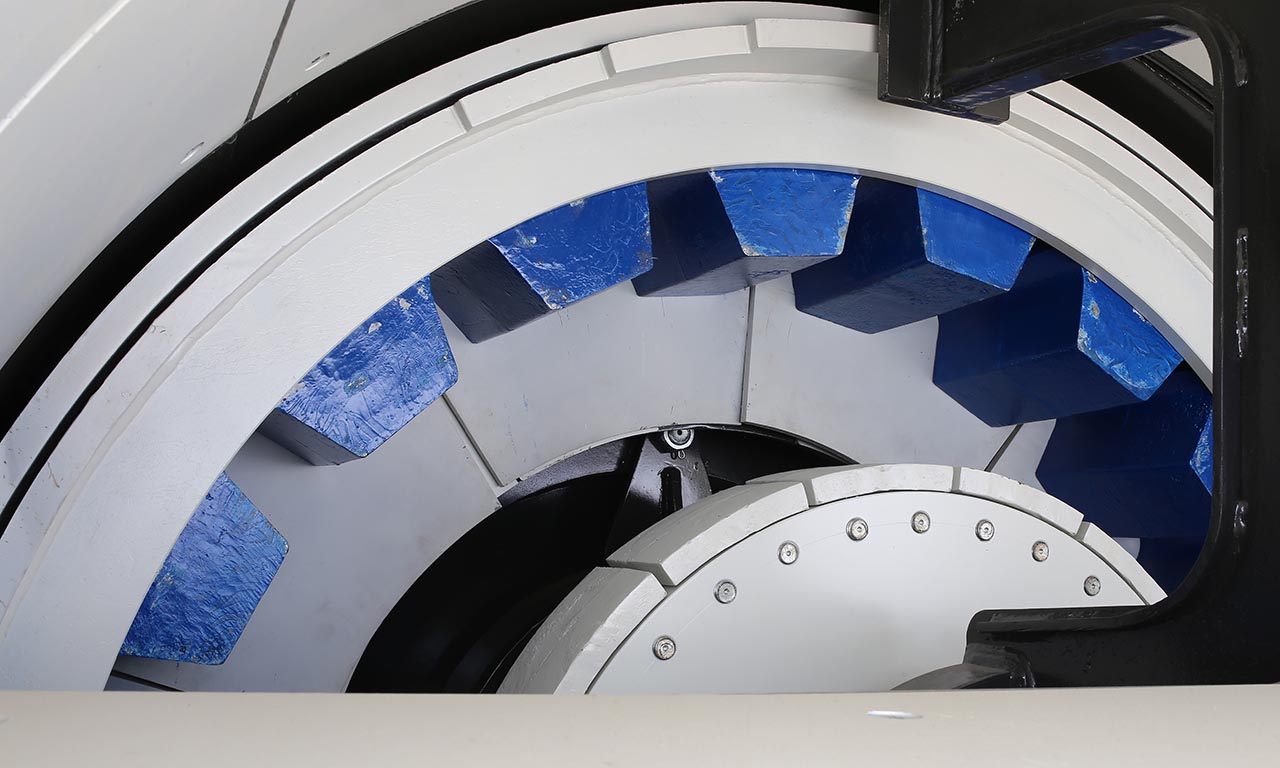

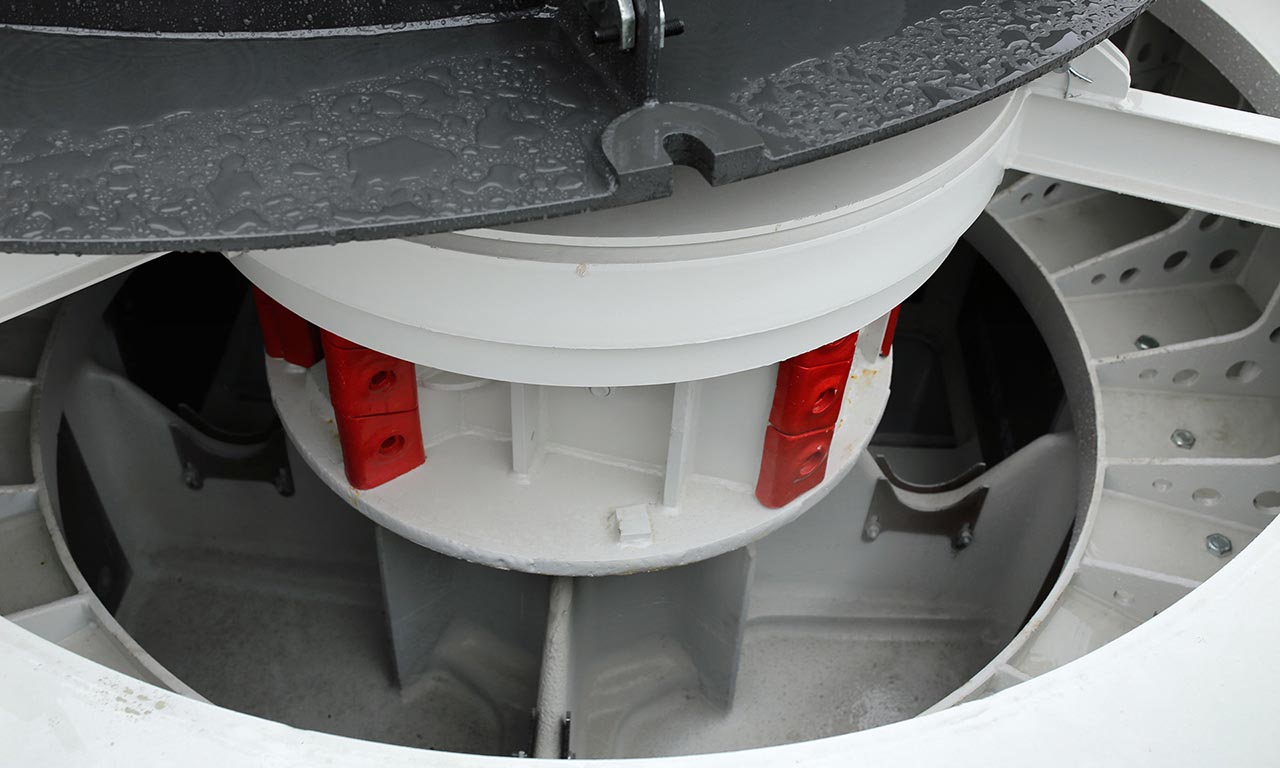

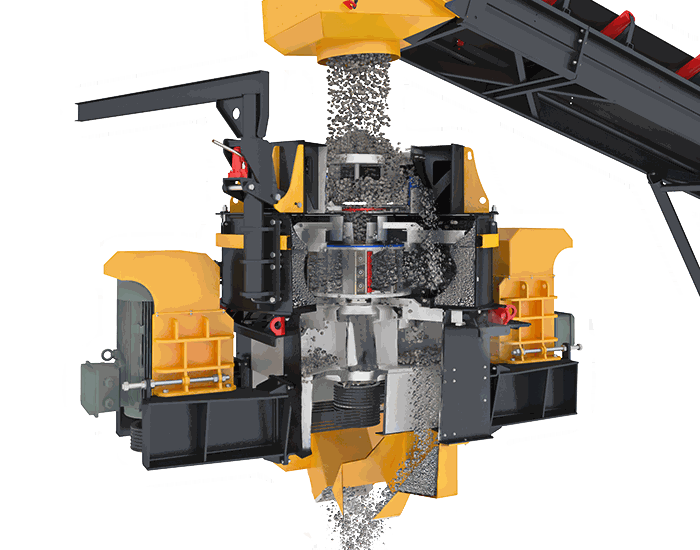

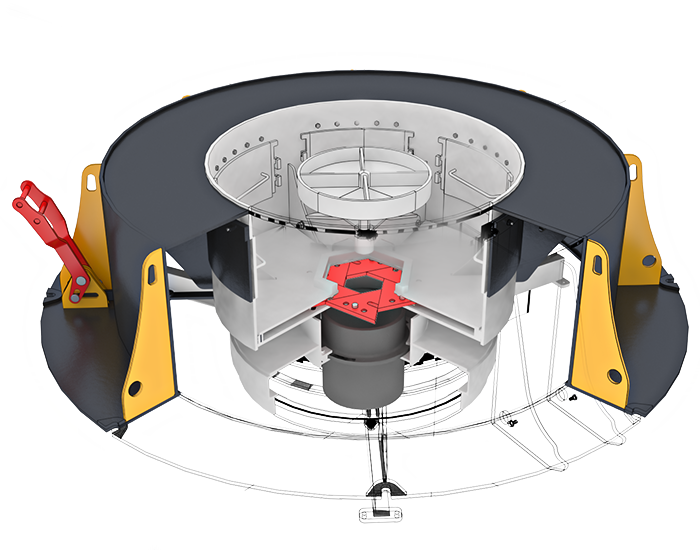

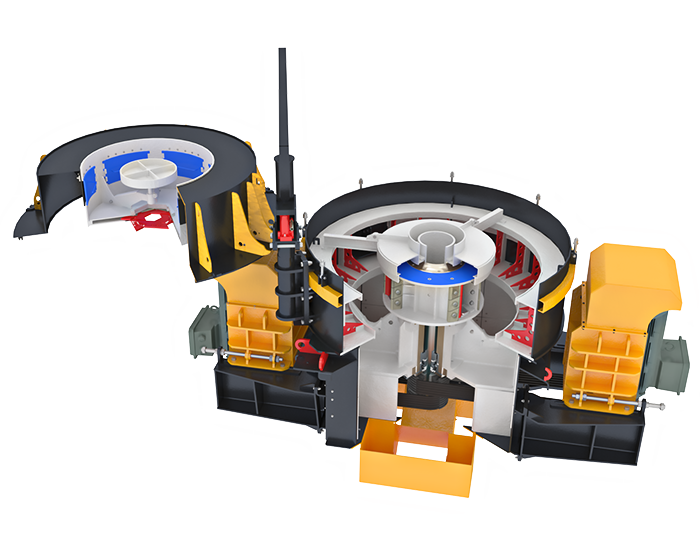

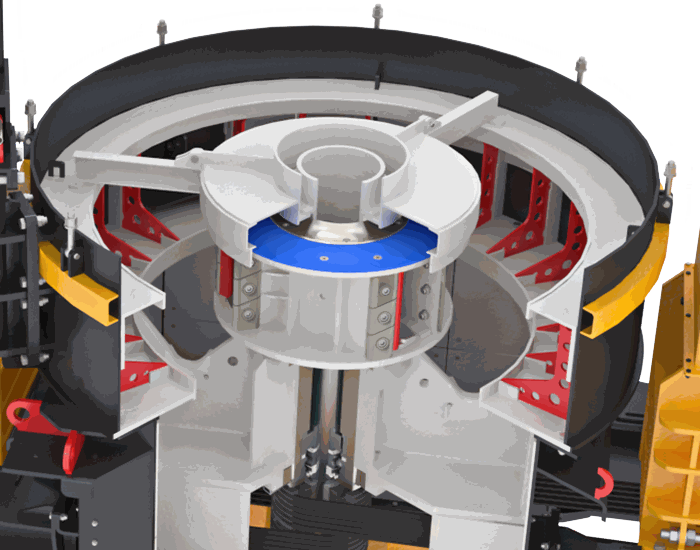

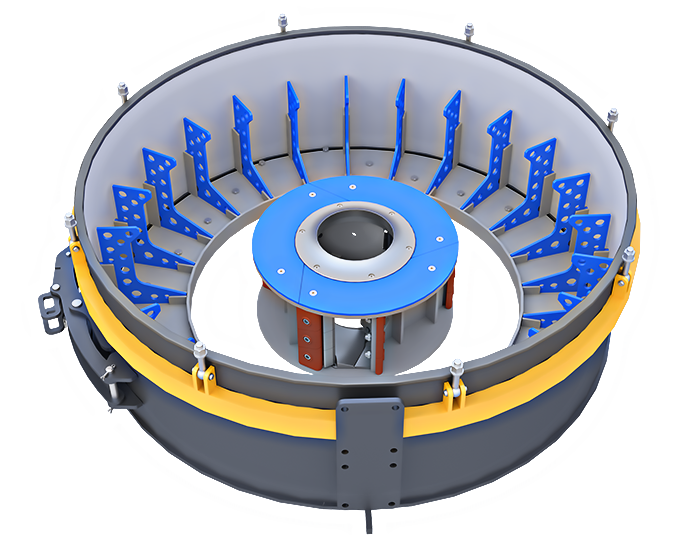

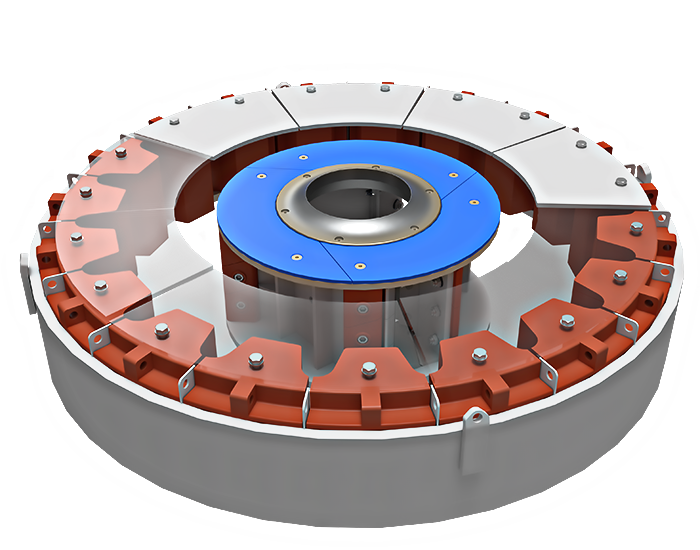

Configuration options include enclosed rotor and rock shelf (ROR), enclosed rotor and anvil ring (ROS). In rock on rock (ROR) configuration, autogenous crushing occurs inside the crusher chamber between material thrown from rotor and material resting on rock shelf or material springing back from rock shelf. In rock on steel (ROS) configuration, impact crushing on anvils and also autogenous crushing between material springing back from anvils and material thrown from rotor occurs at the same time.

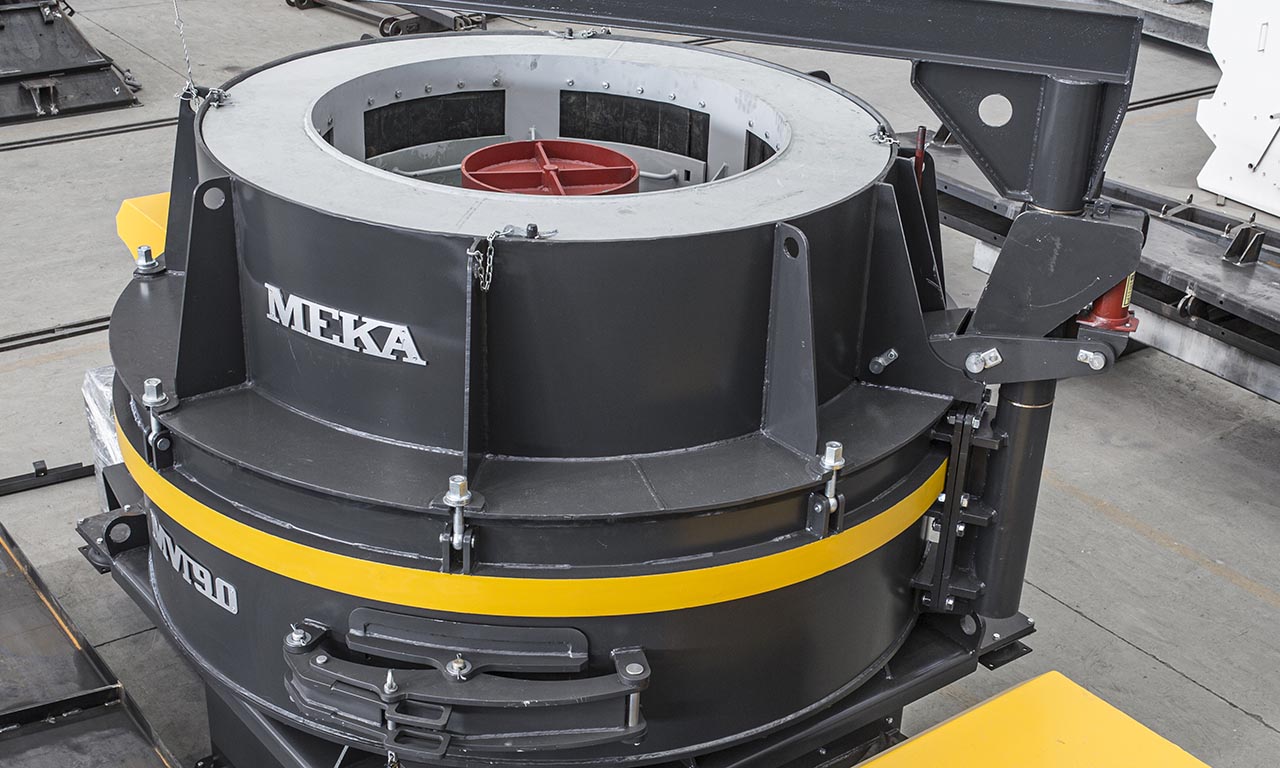

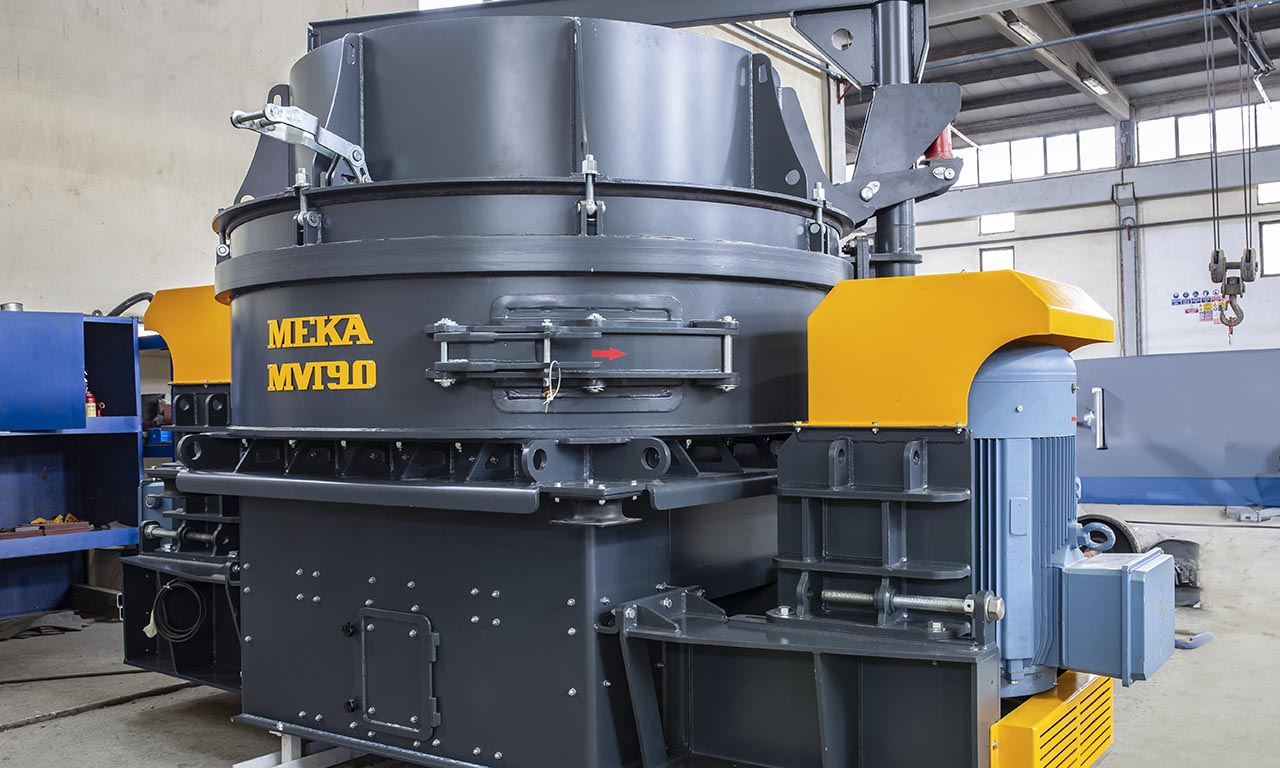

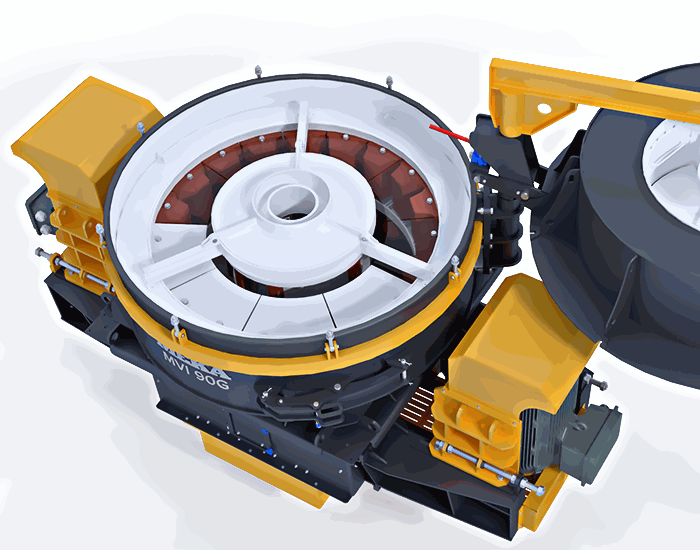

Vertical Shaft Impact Crusher - G Model

Applications

MVI-G Series vertical shaft impact crusher are designed to be used in tertiary or quarternary stage crushing.

These crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial minerals. Crushers can also be used for shaping or removal of soft stone from aggregate.

Why MEKA Vertical Shaft Impact Crusher - G Model?

- Rock on rock design decreases operation costs

- The rock-on-rock crushing principle of the crusher minimises metallic wear resulting in low maintenance and wear costs. The low wear of internal components ensures extremely low contamination of fine products by wearing metal parts.

- Adjustable cascade provides control on final product gradation

- The cascade feed system to introduce a second stream of material, in a controlled quantity, into the crushing chamber turbulence

- Shapes product after a cone crusher

- Can be operated either in open or closed circuit after a cone crusher, depending on the types of aggregates and the specifications required.

- Can accept upto 50mm feed size

- Rock-on-rock technology minimises wear part requirements.

MEKA Vertical Shaft Impact Crusher - G Model Advantages

-

MEKA Vertical Shaft Impact Crusher - G Model Download Catalogue

Vertical Shaft Impact Crusher - G Model Technical Specifications

MVI 90G

|

MVI 90G

|

MVI 90G

|

MVI 90G

|

MVI 70G

|

MVI 70G

|

MVI 70G

|

MVI 70G

|

|

| Max Feed Size (mm) Max Feed Size (inch) | 50 2 | 50 2 | 50 2 | 50 2 | 35 1 ³/₈ | 35 1 ³/₈ | 35 1 ³/₈ | 35 1 ³/₈ |

| *Capacity (mtph) *Capacity (stph) | 200 220 | 300 330 | 200 220 | 300 330 | 120 130 | 160 175 | 120 130 | 160 175 |

| Power (kW) Power (HP) | 200-250 275-340 | 2x110-200 2x150-275 | 200-250 275-340 | 2x110-200 2x150-275 | 110-160 150-220 | 2x110 2x150 | 110-160 2x150-220 | 2x110 2x220 |

| Speed (rpm) Speed (rpm) | 1400-1800 1400-1800 | 1400-1800 1400-1800 | 1400-1800 1400-1800 | 1400-1800 1400-1800 | 1500-2100 1500-2100 | 1500-2100 1500-2100 | 1500-2100 1500-2100 | 1500-2100 1500-2100 |

| **Weight (kg) **Weight (lbs) | 8590 18932 | 9400 20718 | 10990 24222 | 11800 26007 | 4900 10800 | 5550 12232 | 6300 13885 | 6950 15318 |

*For material weighing 1.6 t/m³ or 100 lbs/ft³. Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture content,crushability of the material, crusher rpm, installed power and the crushing circuit design.

**Weights shown do not include drive motor package, support legs, maintenance platform, inlet and outlet chutes

What is Vertical Shaft Impact Crusher - G Model?

Vertical shaft impact crusher is a tertiary or quaternary crusher, and crushes the material fed into the rotor by accelerating and throwing them outwards against the crushing chamber. They utilize impact force to manufacture sand and aggregate to meet the required specifications for concrete and asphalt.

It has a wide range of uses from soft to hard, non-abrasive to abrasive materials in tertiary and quaternary stages for the production of sand and aggregates ,metal and industrial mineral processes.