Simply fill out the form to review our comprehensive catalog of product solutions for crushing, screening, and mining equipment.

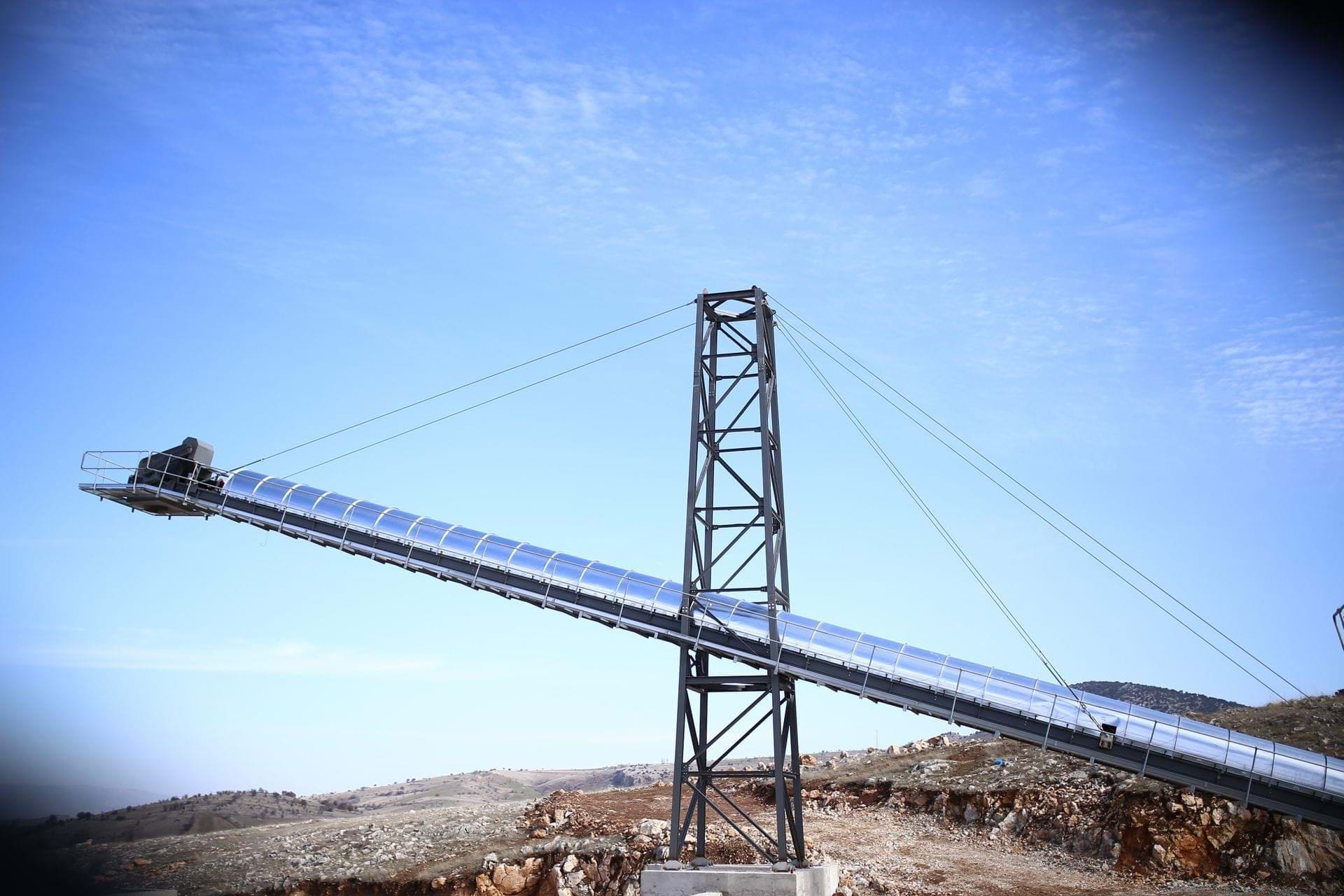

Belt Conveyor

The quality of conveyor systems in quarries and mining sites is crucial in establishing a trouble-free connection between the crushing and screening equipment. Thus, MEKA belt conveyors are made of a solid bended steel frame and equipped with the best solutions to build and maintain trust with our customers.

Belt Conveyor Optional Features

Belt conveyor systems can be customized with various optional features according to the area of use and customer needs. It is possible to offer different solutions depending on the structure of the conveyor, its carrying capacity, the working environment and the type of material to be transported. While the belt width and length are among the basic elements affecting the overall performance of the system, the belt material may also vary if needed. Heat-resistant, oil and chemical-resistant, antistatic or food-approved belt types can be preferred according to the purpose of use of the system.