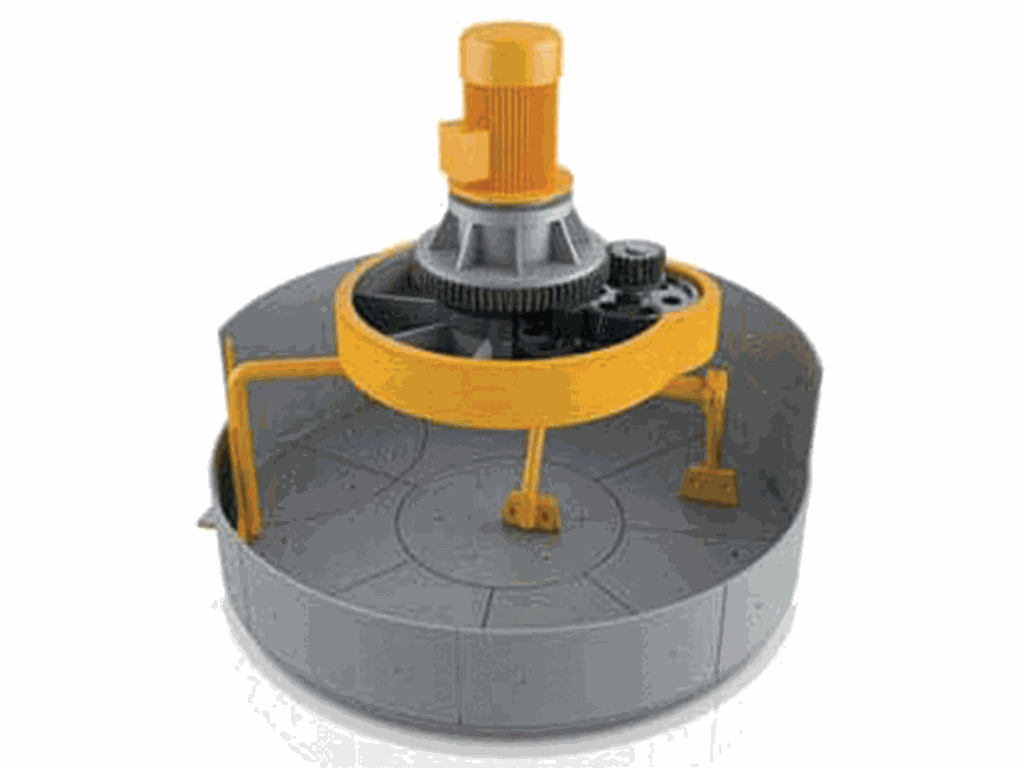

A concrete mixer is a piece of equipment used to create a homogeneous concrete mixture. Concrete mixers typically use a rotating drum or a mixing cylinder. This rotating system allows materials such as cement, sand, water, and aggregate to mix together and form concrete. The mixer’s rotational movement ensures a uniform mix and helps produce high-quality concrete.

Planetary Concrete Mixers

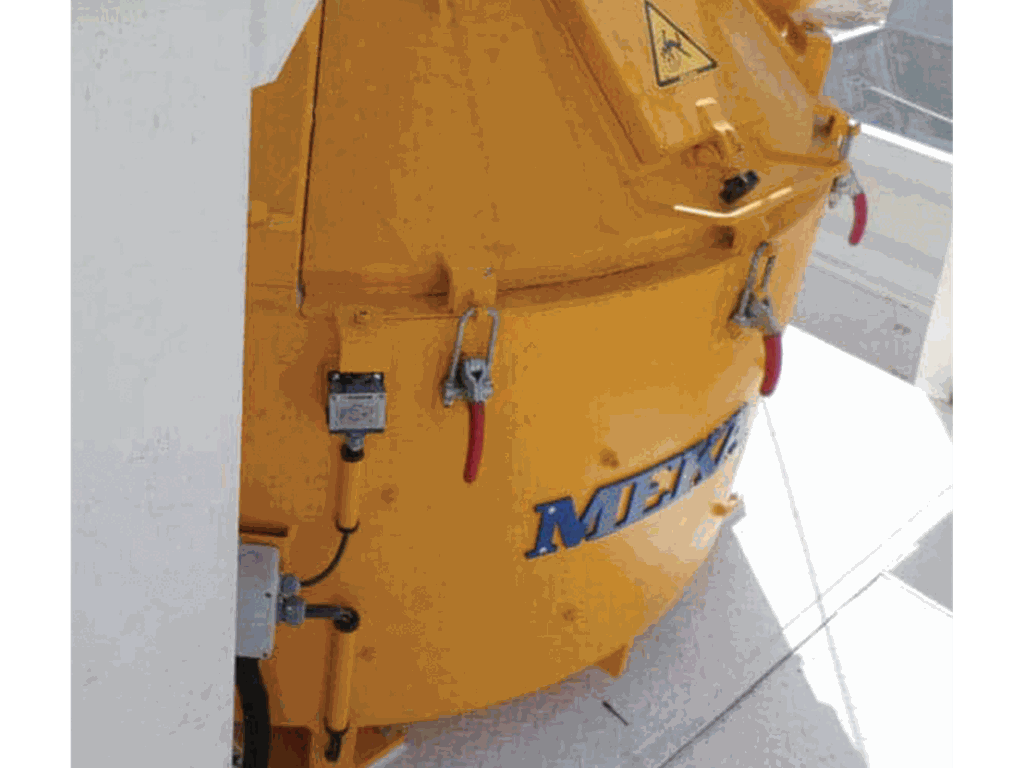

Achieving the desired homogeneity and workability of modern within the shortest period possible, is often the most critical phase of production, therefore, the need for reliable, high quality mixing equipment is essential. A MEKA with a MEKA Planetary at its heart is a combination you can always rely on. MEKA offers an extensive range of high performance – Single Shaft, Twin Shaft, and Planetary with variety of different capacities, ensuring we comply with every requirement. MEKA Planetary have proven to be reliable and built to the highest quality, resulting in MEKA equipment being the choice of many professionals, in over 70 countries around the world.

Planetary Concrete Mixers Advantages

Planetary Concrete Mixers Technical Specifications

MB-P 0,33 |

MB-P 0,5 |

MB-P 1,0 |

MB-P 2,0 |

|

| Types | MB-P 0,33 m³ MB-P 0.43 yd³ | MB-P 0,5 m³ MB-P 0.65 yd³ | MB-P 1,0 m³ MB-P 1.3 yd³ | MB-P 2,0 m³ MB-P 2.6 yd³ |

| Loading Dry Capacity | 0,5 m³ 0.65 yd³ | 0,75 m³ 1.0 yd³ | 1,5 m³ 1.95 yd³ | 3,0 m³ 3.9 yd³ |

| Fresh Capacity | 0,41 m³ 0.53 yd³ | 0,625 m³ 0.8 yd³ | 1,25 m³ 1.62 yd³ | 2,5 m³ 3.25 yd³ |

| Compacted Output | 0,33 m³ 0.43 yd³ | 0,5 m³ 0.65 yd³ | 1,0 m³ 1.3 yd³ | 2,0 m³ 2.6 yd³ |

| Motor Power | 15 kW 20 Hp | 18,5 kW 25 Hp | 45 kW 60 Hp | 90 kW 120 Hp |

| Weight | 1.900 kg 4,190 lbs | 2.620 kg 5,775 lbs | 5.380 kg 11,860 lbs | 8.900 kg 19,620 lbs |

| Side Scraper | 1 1 | 1 1 | 5.380 kg 1 | 8.900 kg 1 |

| Bottom Scraper | - - | - - | 1 1 | 2 2 |

| Nr. of Stars x Nr. of Blade on Each Star | 1x2 1x2 | 1x2 1x2 | 2x2 2x2 | 3x3 3x3 |

| Star RPM / RPM | 46/min - 17/min 46/min - 17/min | 46/min - 16/min 46/min - 16/min | 42/min - 12/min 42/min - 12/min | 33/min - 9/min 33/min - 9/min |

| Body | Welded, SAND BLASTED and Layer Painted (Prime+Color) | |||

| Paint | JOTUN (Norway) / KANSAI (Japan), Thickness 120-200 micron | |||

| Gearbox | MEKA Hydrocoupling with the "Soft Start" function | |||

| Motor Safety | Adjustable Thermic Overload Protection Relay SIEMENS (Germany) | |||

| Mixing Shaft/Arms/Scrap | Robust shaft made from forged steel / Arms from cast steel, replaceable | |||

| Shaft /Arms Alignment | Ultra precision CNC robot machine with strict quality control | |||

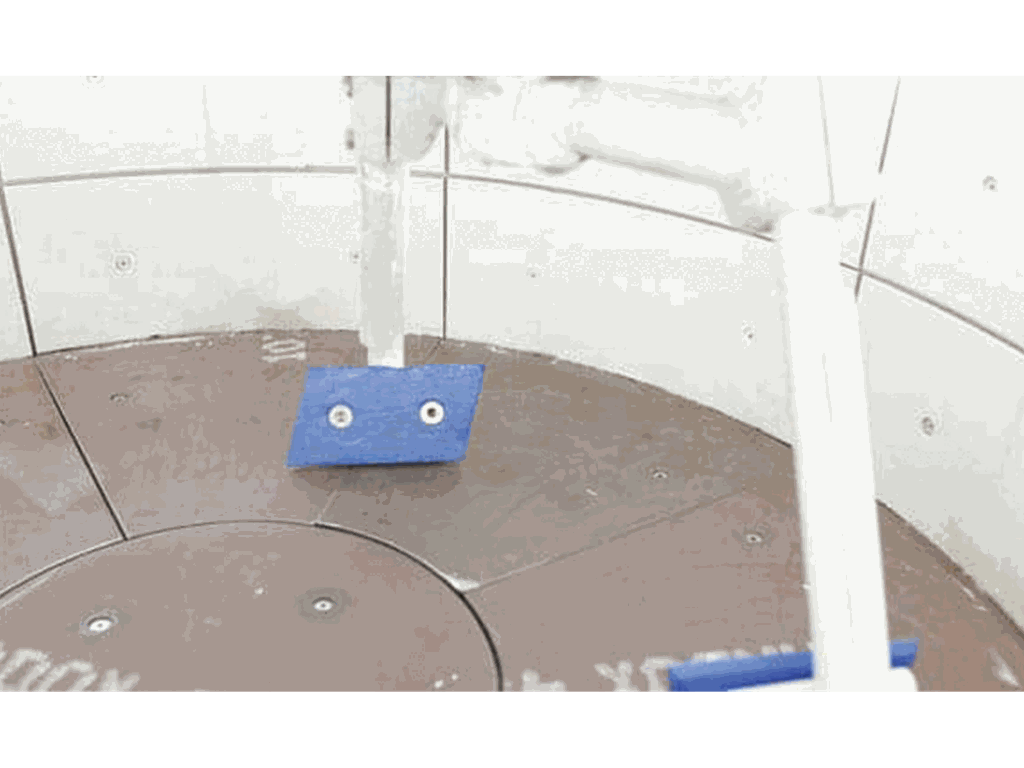

| Side Body Wearing Plates | ST52 - 10 mm thickness, replaceable | |||

| Main Body Wearing Plates | HARDOX 500 (Hardness 500 BH) - 12 mm thickness, replaceable | |||

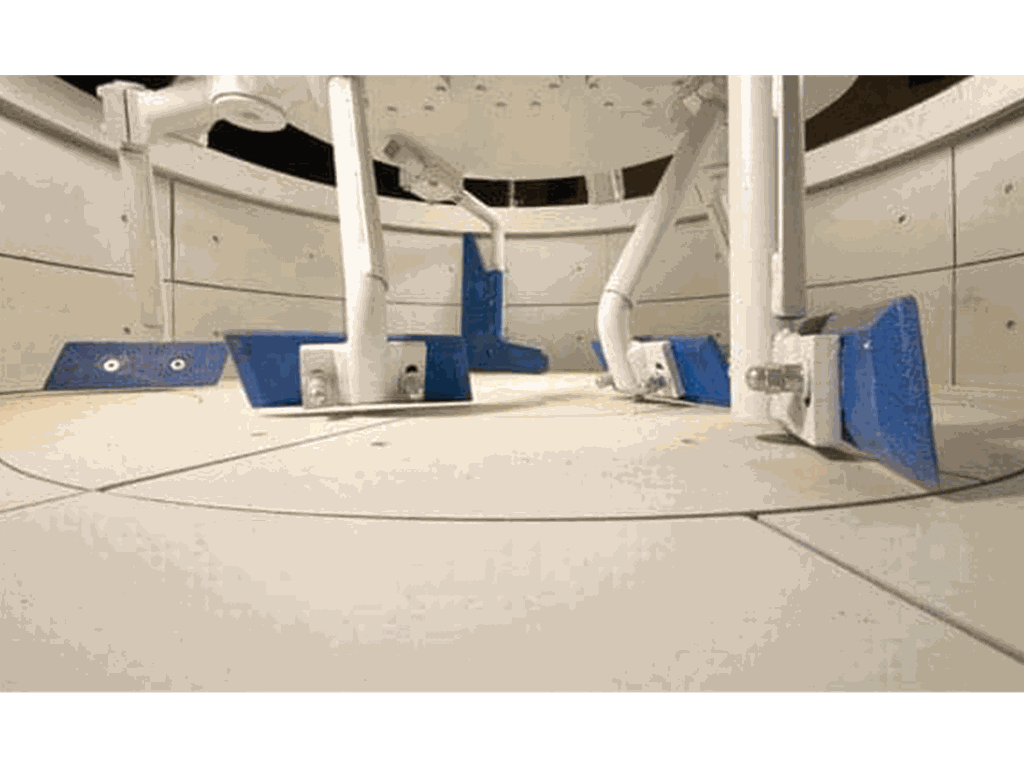

| Mixing Arm/Scraper Wearing Plates | Ni Hard 4 (Hardness 600 Brinell) - 20 mm thickness, replaceable | |||

| Automatic Lubrication | Self lubrication by distribution of oil from crankcase via gears | |||

| Discharge Gate | Hydraulic, rotary with manual pump for emergency discharge | |||

| Nr. of Discharge Gates | 1, optional installation of 2nd gate | |||

| Discharge Control | 2 switches with wide range control in automation (time for opening, time for waiting) | |||

| Water Distribution | From nozzles over arms, discharge by gravity | |||

| Emergency Stop Button | Lockable, according to CE regulations | |||

| Dust Suppression | By-Pass system connecting the Cement Scales and Agg. Holding Hopper | |||

| Maintenance Cover | With safety switch, wide, dustproof, including inspection hatch with safety grid | |||

| Wiring | Completely pre-wired to the IP55 Junction Box on main chassis | |||

| Discharge Chute | With replaceable wearing liners | |||

-

Planetary Concrete Mixers Downloadable Files

Concrete Mixers Optional Features

Concrete mixers are essential equipment in the construction industry, enabling the rapid and efficient mixing of concrete. These mixers ensure a homogeneous blend of concrete, contributing to the production of high-quality and durable concrete on construction sites. They are commonly used in concrete production plants and construction sites for transporting and pouring concrete.

Concrete mixers are available in various capacities and can be adapted to meet different project needs, from large-scale construction projects to smaller applications. Typically, mixers have capacities ranging from 4 m³ to 10 m³, but some models may have smaller or larger capacities depending on specific requirements.

Concrete mixers are widely used in the construction industry. They are essential in various projects, from residential buildings to infrastructure works, road construction projects, and commercial buildings. Concrete mixers are indispensable on construction sites, especially for concrete pouring processes. They are also frequently used in concrete production plants.

The capacity of concrete mixers typically ranges from 4 m³ to 10 m³. However, with custom designs, smaller or larger capacity mixers can also be produced. The mixer capacity is determined based on the scale of the construction project and the daily concrete requirement. Smaller capacity mixers are sufficient for small projects, while higher-capacity mixers are preferred for larger projects.

Regular maintenance of concrete mixers is essential for ensuring their long lifespan and efficient operation. The drum and motor should be inspected and cleaned regularly. After each mixing process, any remaining concrete should be removed, and surfaces should be lubricated. Additionally, gears, tires, and other moving parts should be periodically checked and replaced or lubricated if necessary. Following the manufacturer’s maintenance guidelines helps keep the mixer operating efficiently.

The decision to rent or buy a concrete mixer depends on the size and duration of the project. For short-term projects, renting a concrete mixer may be more cost-effective. However, for long-term or large-scale projects, purchasing a mixer can be more economical. Buying ensures continuous availability and maintenance control, whereas renting is a better option if you need the mixer for a limited period and want to avoid maintenance responsibilities.