Una mezcladora de concreto es un equipo utilizado para crear una mezcla homogénea de concreto. Las mezcladoras de concreto generalmente utilizan un tambor giratorio o un cilindro mezclador. Este sistema de rotación permite que materiales como cemento, arena, agua y áridos se mezclen juntos y formen concreto. El movimiento rotacional de la mezcladora asegura una mezcla uniforme y ayuda a producir concreto de alta calidad.

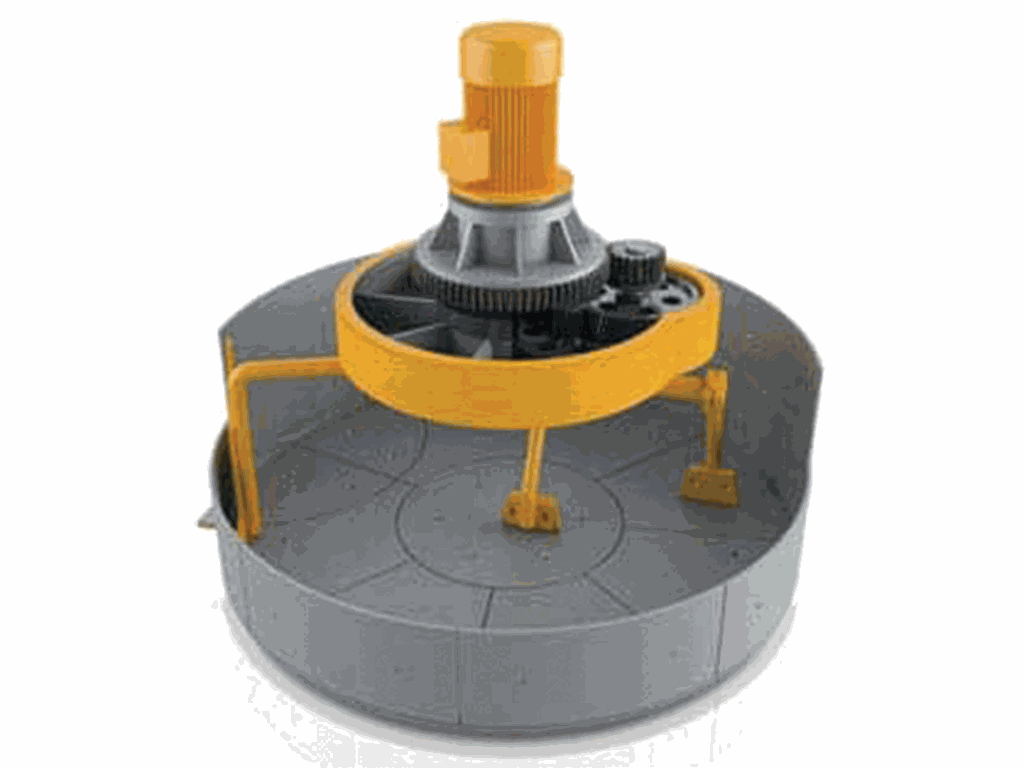

Mezcladores De Concreto Planetarios

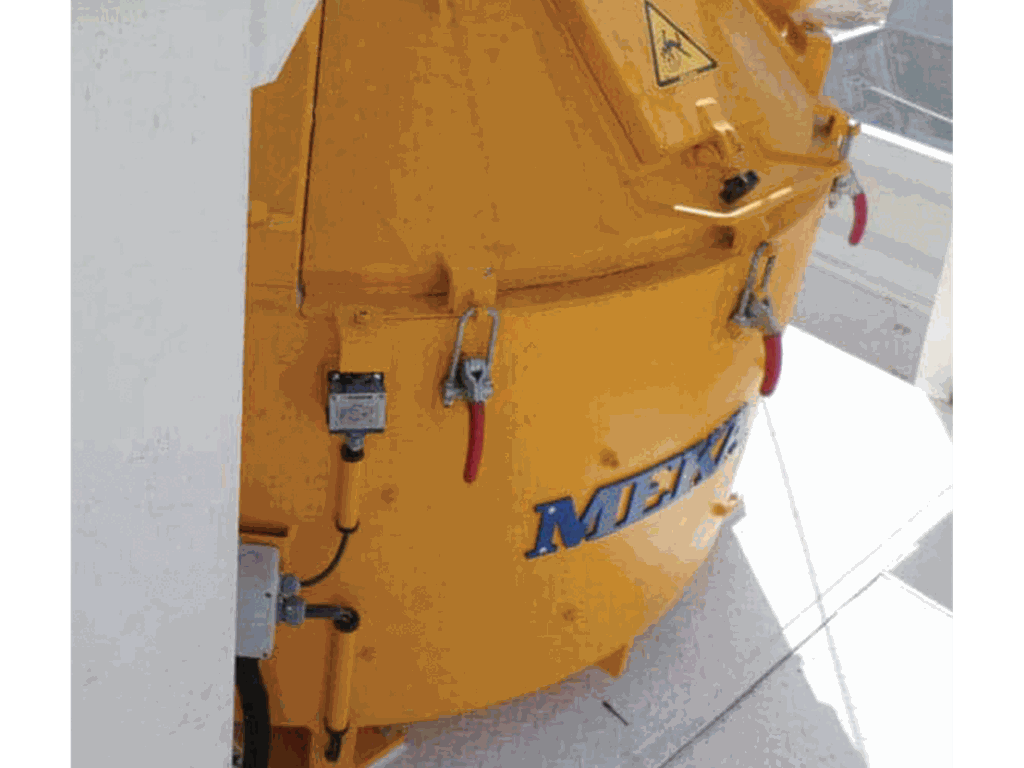

Achieving the desired homogeneity and workability of modern concrete mixtures, within the shortest period possible, is often the most critical phase of concrete production, therefore, the need for reliable, high quality mixing equipment is essential. A MEKA Concrete Plant with a MEKA Planetary Concrete Mixer at its heart is a combination you can always rely on. MEKA offers an extensive range of high performance concrete mixers – Single Shaft, Twin Shaft, and Planetary with variety of different capacities, ensuring we comply with every concrete mixing requirement. MEKA Planetary Concrete Mixers have proven to be reliable and built to the highest quality, resulting in MEKA equipment being the choice of many professionals, in over 70 countries around the world.

Mezcladores De Concreto Planetarios Ventajas

Mezcladores De Concreto Planetarios Especificaciones Técnicas

MB-P 0,33 |

MB-P 0,5 |

MB-P 1,0 |

MB-P 2,0 |

|

| Tipos | MB-P 0,33 m³ MB-P 0.43 yrd³ | MB-P 0,5 m³ MB-P 0.65 yrd³ | MB-P 1,0 m³ MB-P 1.3 yrd³ | MB-P 2,0 m³ MB-P 2.6 yrd³ |

| Carga de capacidad seca | 0,5 m³ 0.65 yrd³ | 0,75 m³ 1.0 yrd³ | 1,5 m³ 1.95 yrd³ | 3,0 m³ 3.9 yrd³ |

| Capacidad concreto fresco | 0,41 m³ 0.53 yrd³ | 0,625 m³ 0.8 yrd³ | 1,25 m³ 1.62 yrd³ | 2,5 m³ 3.25 yrd³ |

| Salida de concreto compactado | 0,33 m³ 0.43 yrd³ | 0,5 m³ 0.65 yrd³ | 1,0 m³ 1.3 yrd³ | 2,0 m³ 2.6 yrd³ |

| Poder de Motor | 15 kW 20 Hp | 18,5 kW 25 Hp | 45 kW 60 Hp | 90 kW 120 Hp |

| Peso del mezclador | 1.900 kg 4,190 lbs | 2.620 kg 5,775 lbs | 5.380 kg 11,860 lbs | 8.900 kg 19,620 lbs |

| Rascador lateral | 1 1 | 1 1 | 5.380 kg 1 | 8.900 kg 1 |

| Raspador inferior | - - | - - | 1 1 | 2 2 |

| Nr. de Estrellas x Nr. de Blade en cada estrella | 1x2 1x2 | 1x2 1x2 | 2x2 2x2 | 3x3 3x3 |

| Arrancador RPM / mezclador RPM | 46/min - 17/min 46/min - 17/min | 46/min - 16/min 46/min - 16/min | 42/min - 12/min 42/min - 12/min | 33/min - 9/min 33/min - 9/min |

| Cuerpo del mezclador | Welded, SAND BLASTED and Layer Painted (Prime+Color) | |||

| Pintura | JOTUN (Norway) / KANSAI (Japan), Thickness 120-200 micron | |||

| Caja reductora | MEKA Hydrocoupling with the "Soft Start" function | |||

| Seguridad del motor | Adjustable Thermic Overload Protection Relay SIEMENS (Germany) | |||

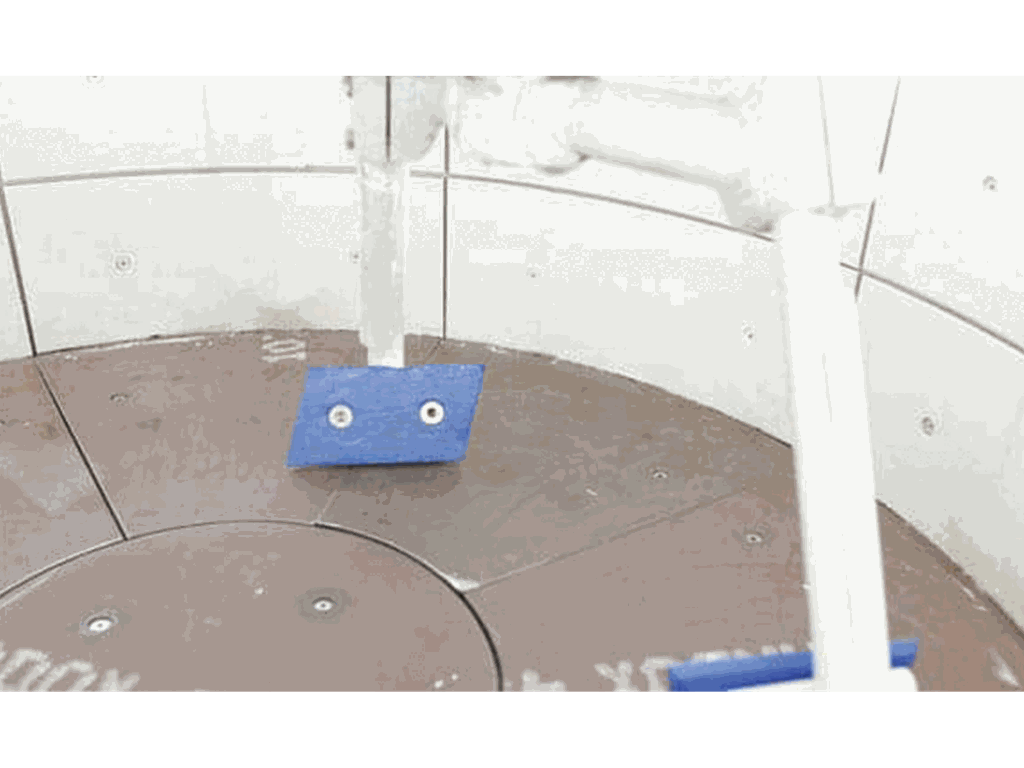

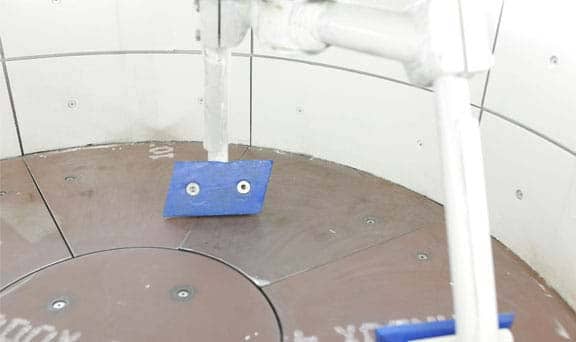

| Mezcla de ejes / brazos | Robust shaft made from forged steel / Arms from cast steel, replaceable | |||

| Eje/Alineación de brazos | Ultra precision CNC robot machine with strict quality control | |||

| Placas laterales que llevan el cuerpo | ST52 - 10 mm thickness, replaceable | |||

| Placas de uso del cuerpo principal | HARDOX 500 (Hardness 500 BH) - 12 mm thickness, replaceable | |||

| Brazo de mezcla/Raspador con placas | Ni Hard 4 (Hardness 600 Brinell) - 20 mm thickness, replaceable | |||

| Lubricación automática | Self lubrication by distribution of oil from crankcase via gears | |||

| Puerta de descarga | Hydraulic, rotary with manual pump for emergency discharge | |||

| Nr. de puertas de descarga | 1, optional installation of 2nd gate | |||

| Control de descarga | 2 switches with wide range control in automation (time for opening, time for waiting) | |||

| Distribución del agua | From nozzles over arms, discharge by gravity | |||

| Paro de emergencia. | Lockable, according to CE regulations | |||

| Supresión de polvo | By-Pass system connecting the Mixer, Cement Scales and Agg. Holding Hopper | |||

| Cubierta de mantenimiento | With safety switch, wide, dustproof, including inspection hatch with safety grid | |||

| Alambrado | Completely pre-wired to the IP55 Junction Box on main chassis | |||

| Canal de descarga | With replaceable wearing liners | |||

-

Mezcladores De Concreto Planetarios Archivos Descargables

Hormigoneras Características Opcionales

Las mezcladoras de concreto son equipos esenciales en la industria de la construcción, que permiten la mezcla rápida y eficiente del concreto. Estas mezcladoras aseguran una mezcla homogénea de concreto, contribuyendo a la producción de concreto de alta calidad y durabilidad en los sitios de construcción. Son comúnmente utilizadas en plantas de producción de concreto y en sitios de construcción para transportar y verter concreto.

Las mezcladoras de concreto están disponibles en varias capacidades y se pueden adaptar para satisfacer las diferentes necesidades de los proyectos, desde grandes proyectos de construcción hasta aplicaciones más pequeñas. General

Las mezcladoras de concreto son ampliamente utilizadas en la industria de la construcción. Son esenciales en diversos proyectos, desde edificios residenciales hasta obras de infraestructura, proyectos de construcción de carreteras y edificios comerciales. Las mezcladoras de concreto son indispensables en los sitios de construcción, especialmente para los procesos de vertido de concreto. También se utilizan frecuentemente en plantas de producción de concreto.

La capacidad de las mezcladoras de concreto generalmente varía entre 4 m³ y 10 m³. Sin embargo, con diseños personalizados, también se pueden producir mezcladoras de capacidad más pequeña o más grande. La capacidad de la mezcladora se determina en función de la escala del proyecto de construcción y la necesidad diaria de concreto. Las mezcladoras de menor capacidad son suficientes para proyectos pequeños, mientras que se prefieren mezcladoras de mayor capacidad para proyectos más grandes.

El mantenimiento regular de las mezcladoras de concreto es esencial para garantizar su larga vida útil y un funcionamiento eficiente. El tambor y el motor deben inspeccionarse y limpiarse regularmente. Después de cada proceso de mezcla, cualquier concreto restante debe ser retirado, y las superficies deben ser lubricadas. Además, los engranajes, llantas y otras partes móviles deben ser revisados periódicamente y reemplazados o lubricados si es necesario. Seguir las pautas de mantenimiento del fabricante ayuda a mantener la mezcladora funcionando eficientemente.

La decisión de alquilar o comprar una mezcladora de concreto depende del tamaño y la duración del proyecto. Para proyectos a corto plazo, alquilar una mezcladora de concreto puede ser más rentable. Sin embargo, para proyectos a largo plazo o de gran escala, comprar una mezcladora puede ser más económico. Comprar asegura la disponibilidad continua y el control del mantenimiento, mientras que alquilar es una mejor opción si necesita la mezcladora por un período limitado y desea evitar responsabilidades de mantenimiento.