Applications

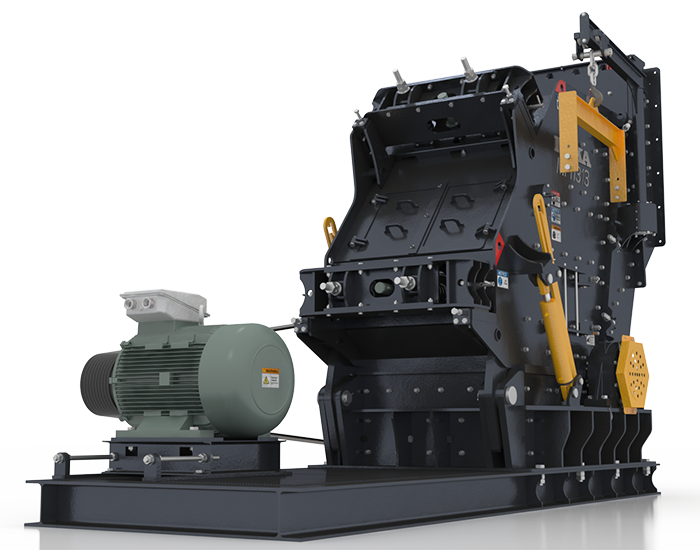

The strength of Primary Impact Crushers(MPI) makes them ideal for diverse applications and configurations.

These crushers can replace large jaw crushers and be fed with material blocks the size of their feed opening. MPI crushers are extremely versatile machines and have proven their effectiveness in a host of missions like crushing low abrasive materials for quarrying, cement industry, concrete and asphalt recycling, and slag recycling.

Why MEKA Primary Impact Crusher?

- Very High Reduction Ratio

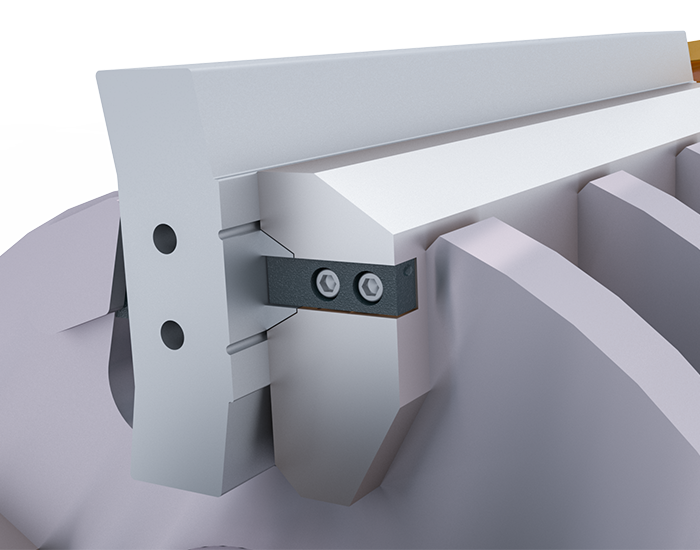

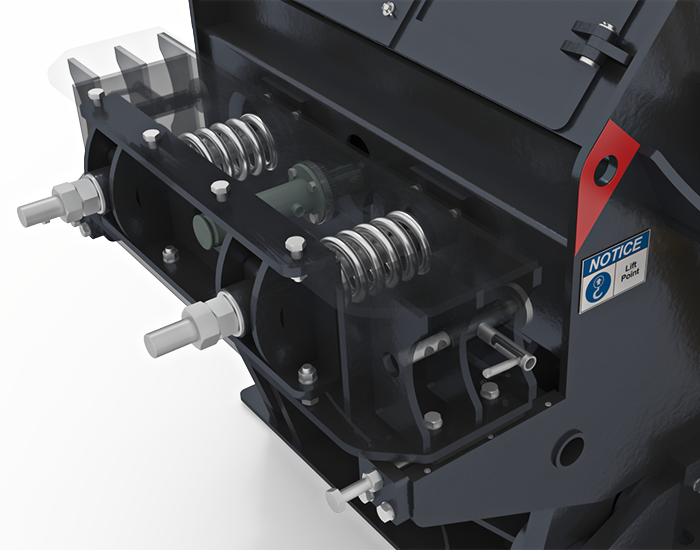

- Primary Impact Crushers achieve a higher reduction with fewer crushing stages, lowering your capital costs and saving energy. The design of crushing chamber with double breaker plates ensures great reduction ratios and with the addition of a third plate, reduction ratio can even be improved.

- Can produce aggregates in a single stage crusher

- With the ability to recirculate material to the MPI range of crushers, it is now possible to achieve single stage crushing. This will allow customers to set up a plant for minimal capital outlay and start producing aggregates quickly and simply, thus enabling a relatively quick return on investments.

- Can accept big boulders

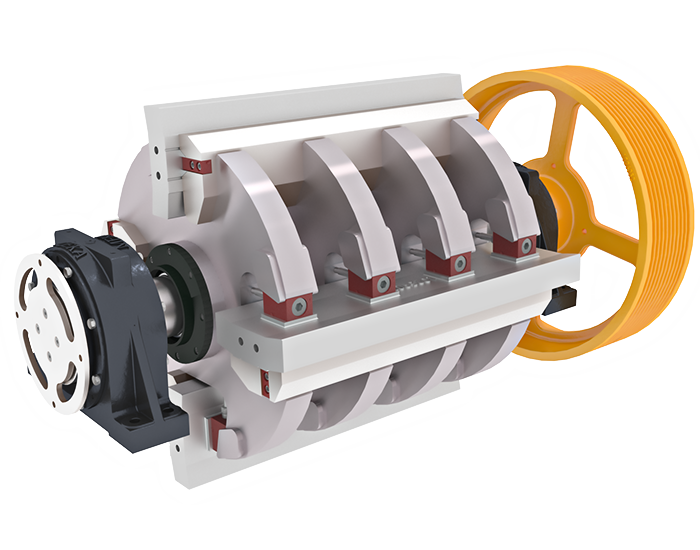

- Large unobstructed feed opening, heavy-duty breaker plates and heavy rotor are designed to accept big feed size for high production.

- Very high throughputs

- Design of the crusher maximizes loading, and with a bigger crushing chamber, the result is a boost in productivity in every type of application.

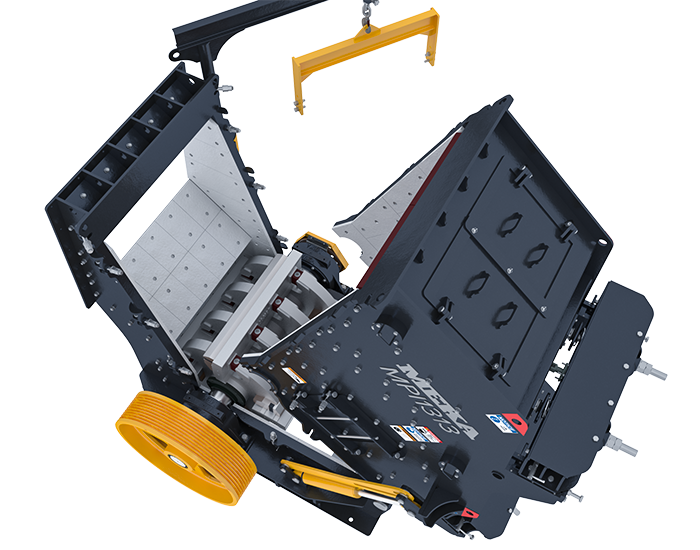

Primary Impact Crusher Gallery

Primary Impact Crusher Technical Specifications

MPI 1111 |

MPI 1012 |

MPI 1114 |

MPI 1313 |

MPI 1515 |

MPI 1620 |

|

| Rotor Diameter (mm) | 1100 | 1100 | 1100 | 1300 | 1500 | 1600 |

| Rotor Width (mm) | 1100 | 1100 | 1400 | 1300 | 1500 | 2000 |

| Feed Opening (mm) | 1140x950 | 1140x840 | 1410x950 | 1340x1000 | 1540x920 | 2040x1400 |

| Maximum Feed Size (mm) | 600 | 600 | 600 | 900 | 850 | 1300 |

| *Capacity (mtph) | 150-200 | 150-200 | 250-350 | 300-500 | 400-600 | 600-950 |

| Power (kW) | 160 | 160 | 200 | 250 | 315 | 500 |

| **Weight (kg) | 15100 | 13150 | 16800 | 22400 | 26800 | 40500 |

*For material weighing 1.6 t/m³ or 100 lbs/ft³.

Minimum capacities are for top feed size of 800 mm (31”) and end product of 100 mm (4”).

Maximum capacities are for top feed size of 600 (24”) mm and end product of 200 mm (8”).

Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture content, crushability of the material, crusher rpm, installed power and the crushing circuit design.

**Weights shown do not include drive motor package, support legs, maintenance platform, inlet and outlet chutes.

What is Primary Impact Crusher?

The primary impact crusher is used in the primary crushing stage of various materials and is a horizontal shaft crusher utilizing impact force to crush the material.

The materials are crushed by the impact force generated by the blowbars on the rotating rotor. With the impact of of material on the blowbars on the rotor, the material hits the opposite breaker plates and a secondary crushing takes place.

Primary impact crushers are designed for high throughput and large feed sizes. High reduction ratio and high production make impact crushers ideal crusher for large capacity projects. Produces cubical end products with high proportions even in the primary stage. Energy cost per ton of product produced is low.