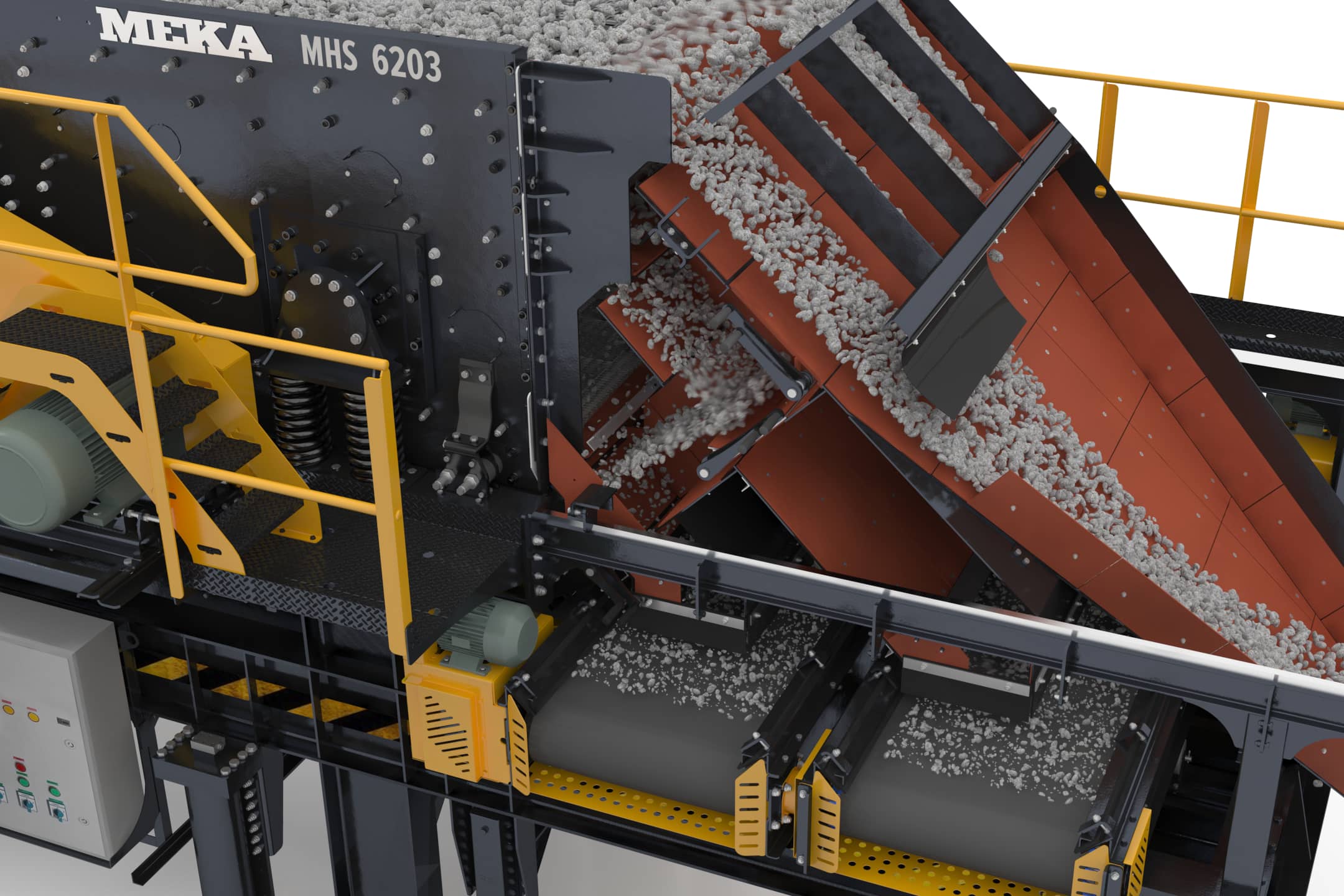

The MP 8203/6203 delivers up to four finished products with exceptional efficiency, excelling in sand production and blending up to 1/4 ratio with its innovative flop gate design.

Special prices for the USA

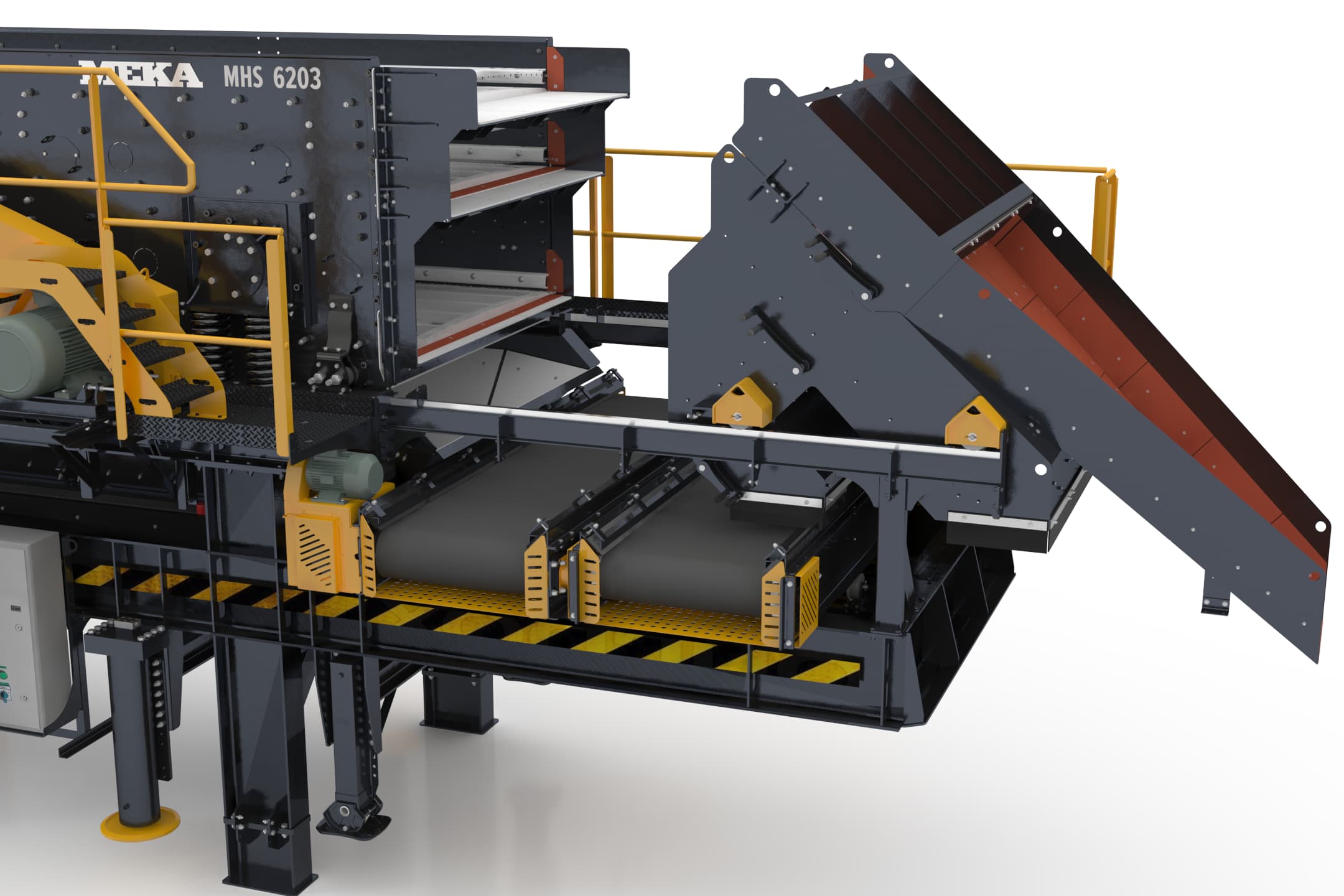

MP Series MEKA Portable Horizontal Screen Plants

The MEKA MP series horizontal screen plants, MP6203 – 8203, a three-deck portable horizontal screen, combines exceptional performance, rugged durability, and eco-friendly efficiency to deliver unmatched results for mining, aggregates, and recycling industries.

Discover MEKA Portable Wash Plants

Why MEKA MP Series Portable Horizontal Screen?

The MEKA MP 8203 - 6203 combines exceptional screening performance, rugged durability, and eco-friendly operation, making it ideal for industries like mining, aggregates, and recycling. With features like an advanced screenbox, unmatched mobility, heavy-duty design, and fully electric drive, it delivers efficiency and reliability for the toughest applications.

Yes, they fully comply with USA homologation standards and is designed to be highway towable. It can be easily transported with a single truck, ensuring convenience and cost efficiency for your operations.

The MP Series Portable Screen Plants are versatile solutions designed for a wide range of applications, including mining, aggregates, sand production, and concrete and asphalt recycling.

MEKA MP Series plants are equipped with MHS Series Horizontal Screens, designed for durability and high stroke capacity. Their three-shaft design enhances G-force, providing superior screening performance compared to other models.

Yes, they are built to handle tough environments. With heavy-duty options, reinforced top decks, and AR 400 perforated plates, they deliver exceptional durability and performance for demanding applications.

Flop Gate System:

Features 4 blending gates per deck, enabling precise material mixing and flexibility in product output.Wing-Type Tail Drum:

Ensures smooth operation for cross and under-screen conveyors, enhancing durability and efficiency.Double AxleMobile Chassis:

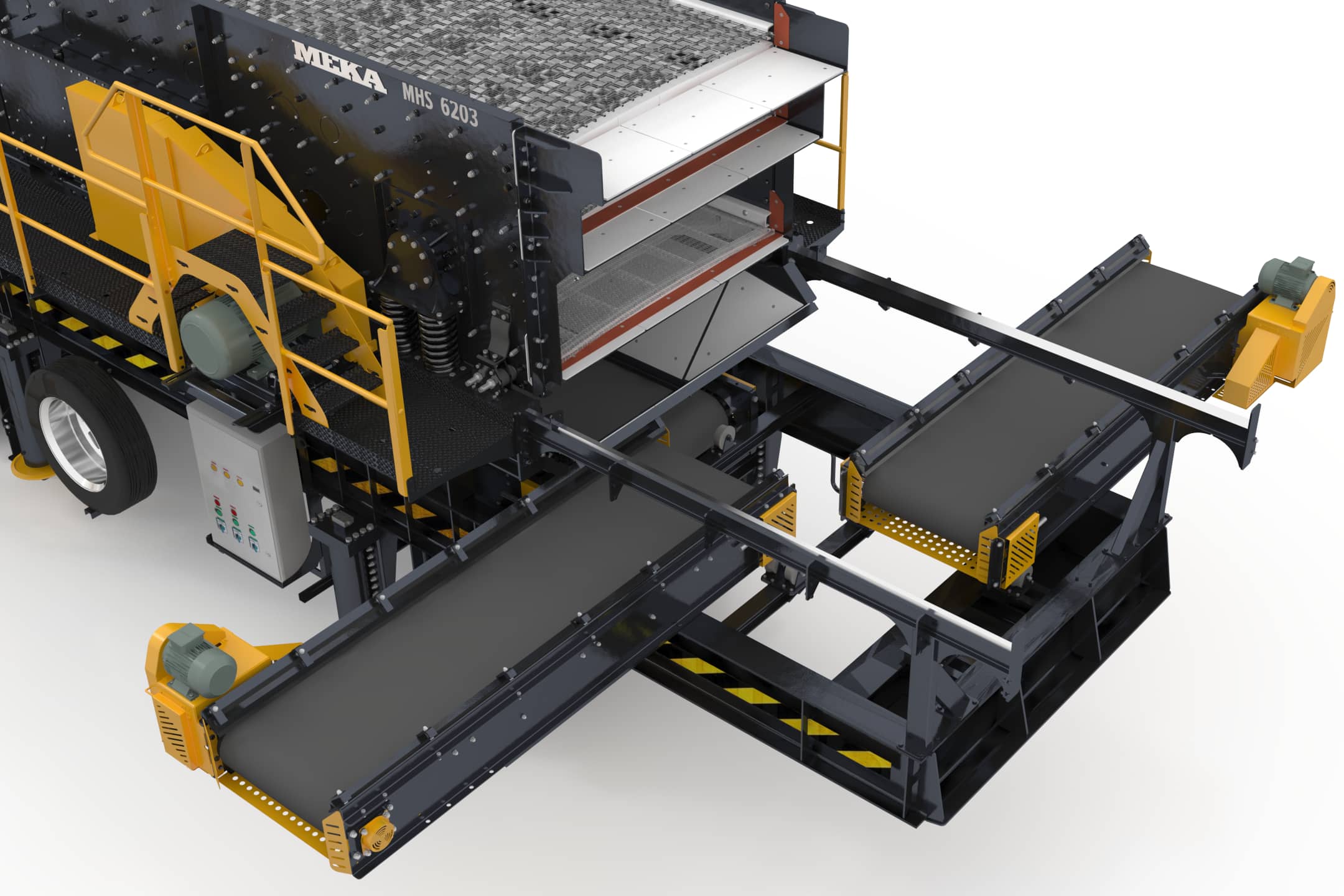

Provides excellent mobility and stability, making it easy to transport and position on-site.Reversible Cross Conveyors with Roll-Away System:

Allows efficient material handling and simplifies maintenance.Triple Shaft Drive System:

Delivers high G-force and superior screening performance, even under demanding conditions.Run-On Jacks:

Simplify installation and setup, reducing downtime and effort.Bi-Directional Cross Conveyors equipped with wing-type tail drums for efficient material handling.

Electrical Control Panel with an additional 11 switches to accommodate stackers and auxiliary equipment.

High-Capacity Screw Washer (MFW 3625 S) with a rising current setup for superior washing efficiency.

Run-On Jacks for quick and effortless setup, saving valuable time.

Triple Shaft Horizontal Screen for precise material separation and durability.

Washing Nozzles strategically placed at each deck for thorough cleaning.

3-Axle Semi-Trailer Design for easy transportation and highway compliance.